Mechanically-jointed integrated board technique for natural width beveled edge board

A natural width, integrated board technology, used in the joining of wooden veneers, other plywood/plywood appliances, manufacturing tools, etc., can solve the problems of limited splicing area, waste of boards, increase in the number of defective plates, etc., to improve splicing The effect of quality, saving sheet, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] The machine assembled integrated board process of the natural width beveled edge board of the present invention specifically includes the following steps:

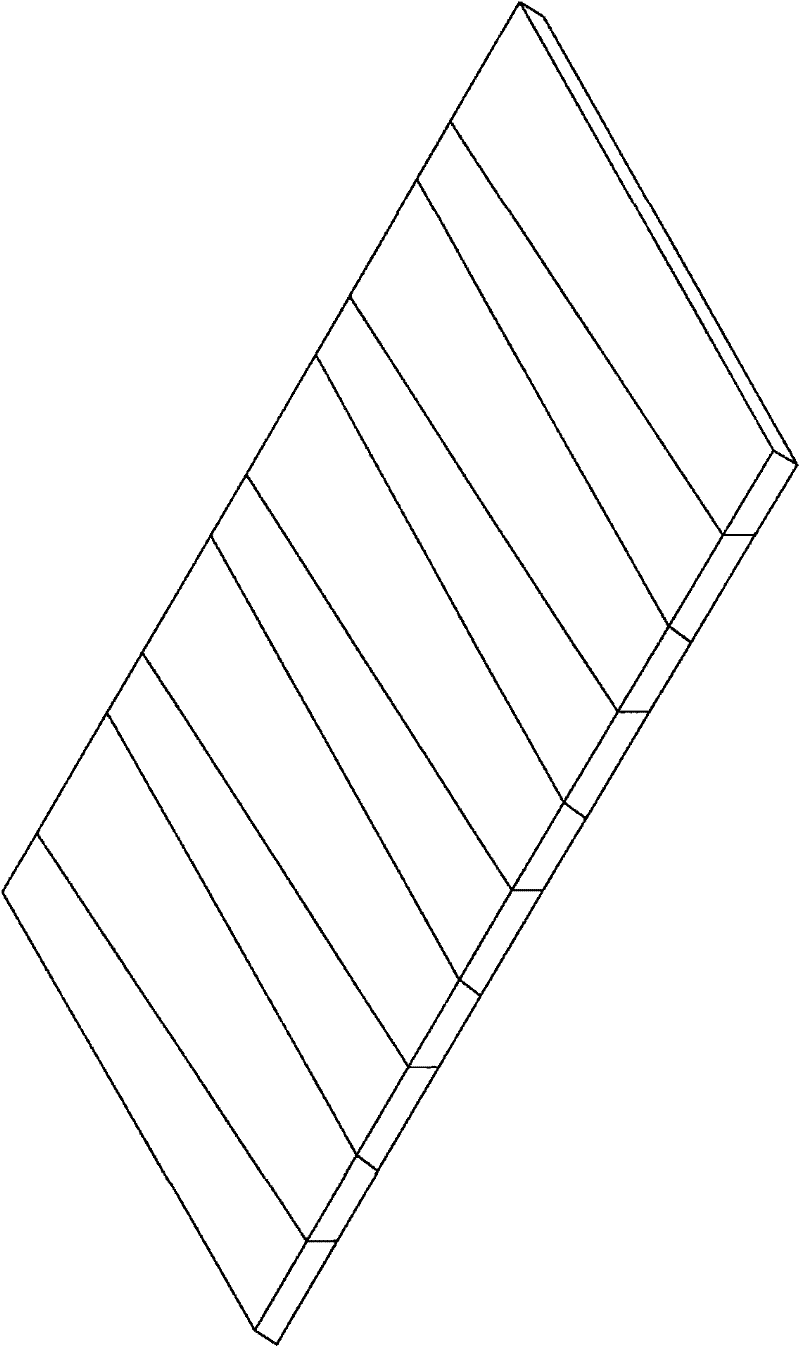

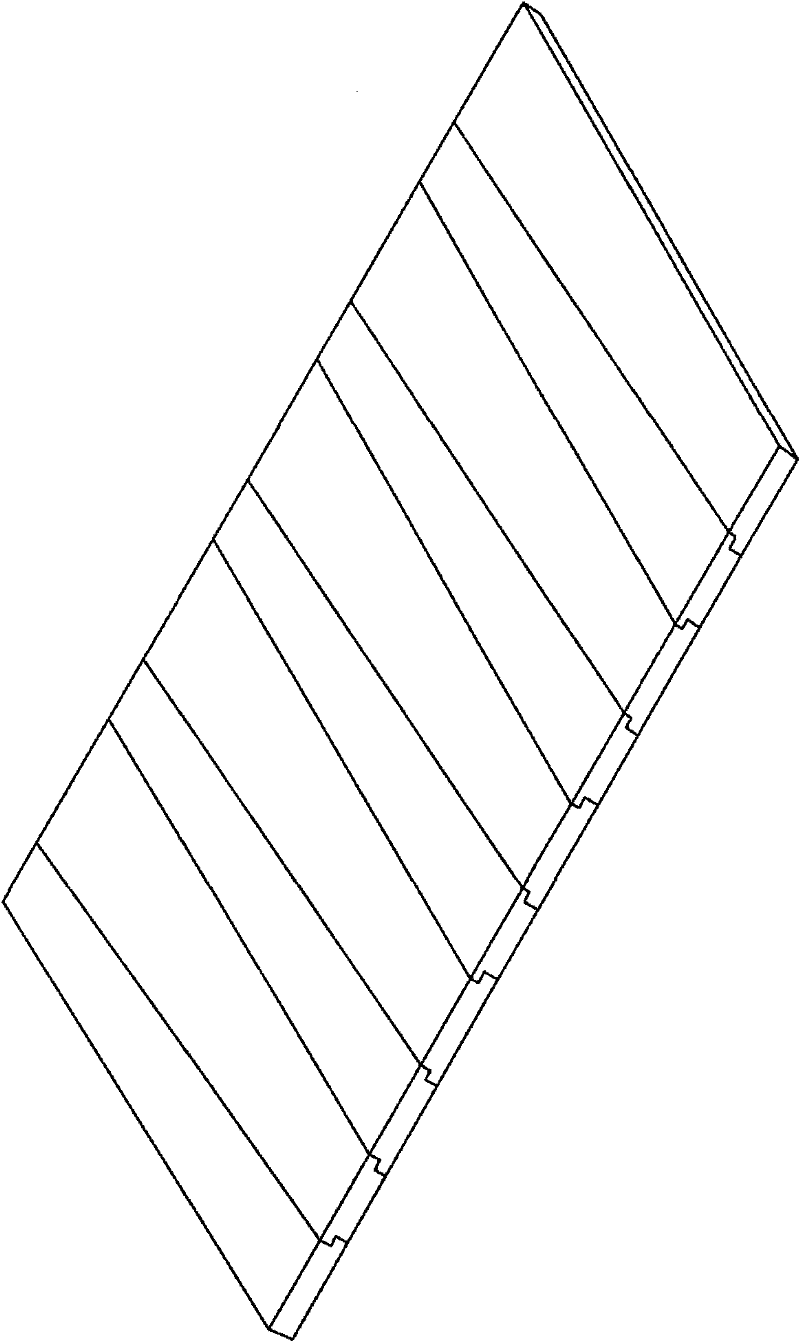

[0019] 1) Saw the original wood board with the natural width of the bark along its two long beveled sides into a standard-slope specification board with an edge-slipping machine, that is, the slope of the two long sides of the machine-sawed specification board are fixed. Such as figure 1 with figure 2 As shown, the boards processed by this process have kept the natural width of the original wood boards to the greatest extent, and the beveled edges of the standard boards can increase the splicing area, which is conducive to improving the splicing quality of the integrated boards.

[0020] 2) Preliminarily arrange multiple pieces of specification boards sawed by the machine in the order of large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com