Corner cabinet

A corner cabinet and cabinet surface technology, applied in the field of corner cabinets, can solve problems such as large color difference, non-adjustable angle, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

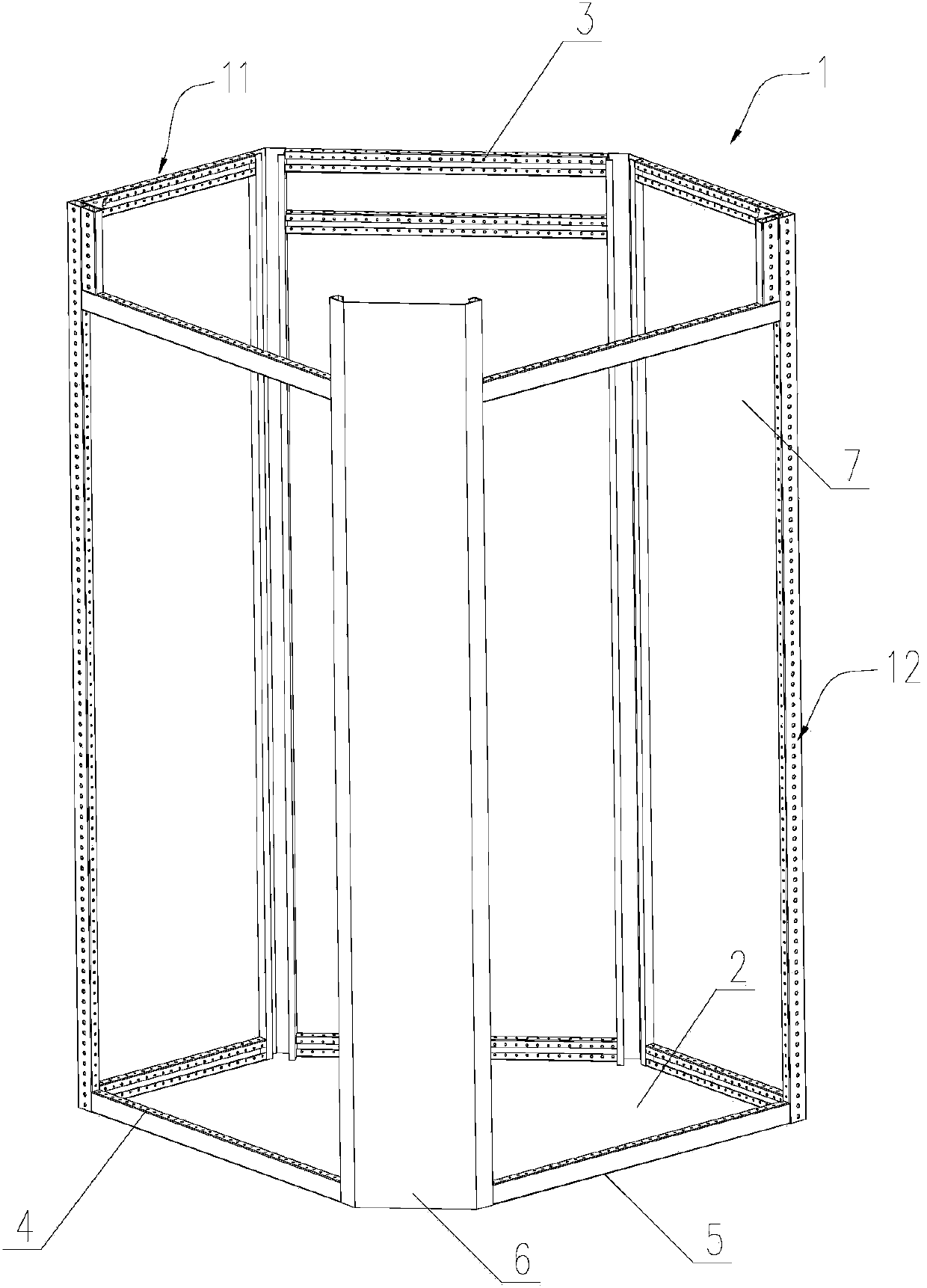

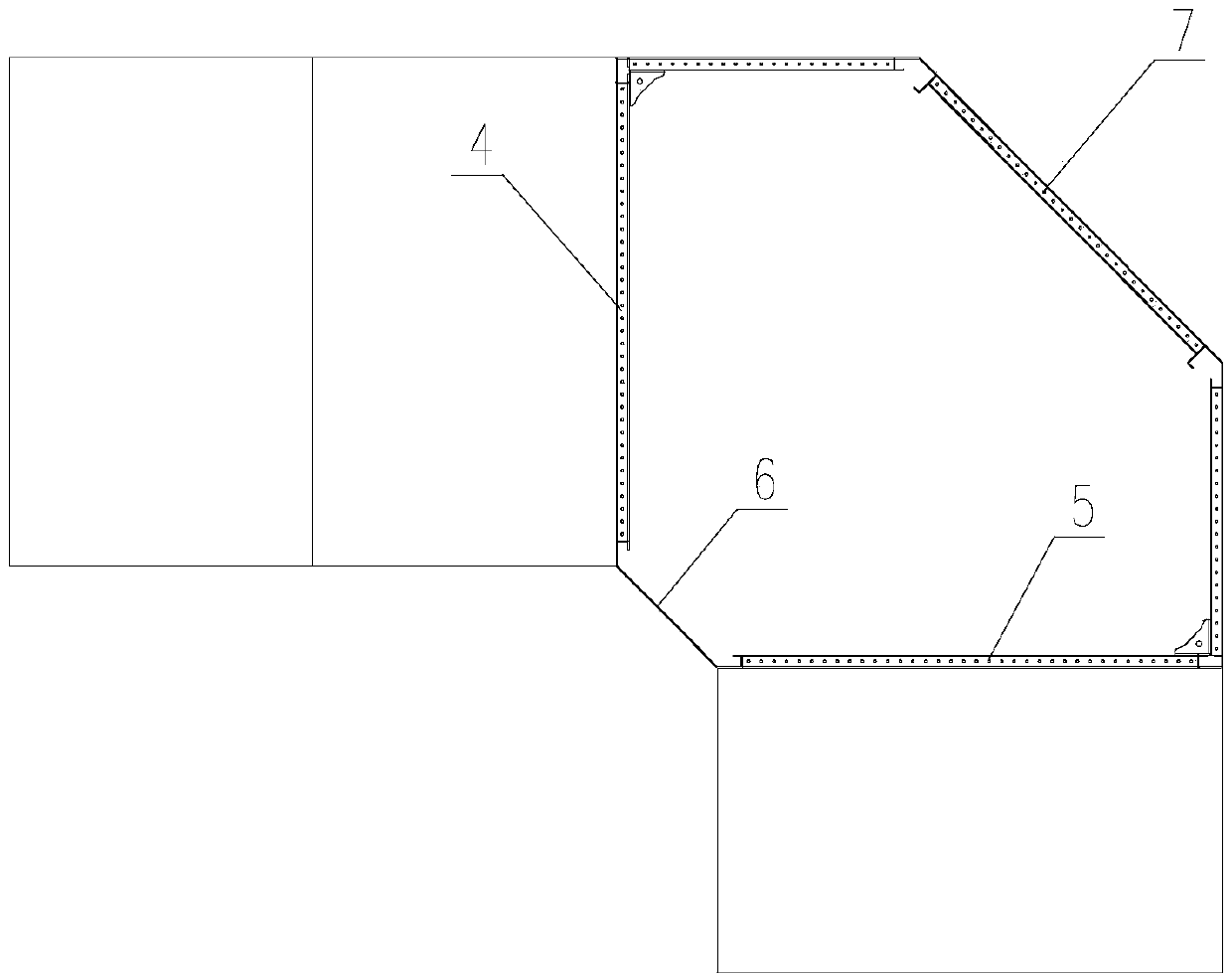

[0025] Such as figure 1 , figure 2 As shown, this embodiment provides a corner cabinet, including a main frame 1 and a sealing plate, wherein the main frame 1 is composed of a plurality of frame units, and the frame units are detachably connected.

[0026] In this embodiment, the detachable connected frame unit is used, and the assembly method used in the installation process of the corner cabinet is used for connection, which overcomes the disadvantage that the angle cannot be adjusted once the welding cabinet is welded. Moreover, the assembly-type installation structure is adopted, and partial parts processing can be realized in the production process of parts, which saves plates and facilitates processing.

[0027] At the same time, the assembled corner cabinet installation structure can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com