Overlay decorating plate

A decorative panel and covering technology, applied in covering/lining, floors, buildings, etc., can solve the problems of complex milling process, difficulty in improving processing efficiency, poor waterproof and dustproof effect at the joints of floor boards, etc., to achieve good anti-corrosion Dust and waterproof effect, save labor intensity, improve the effect of laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

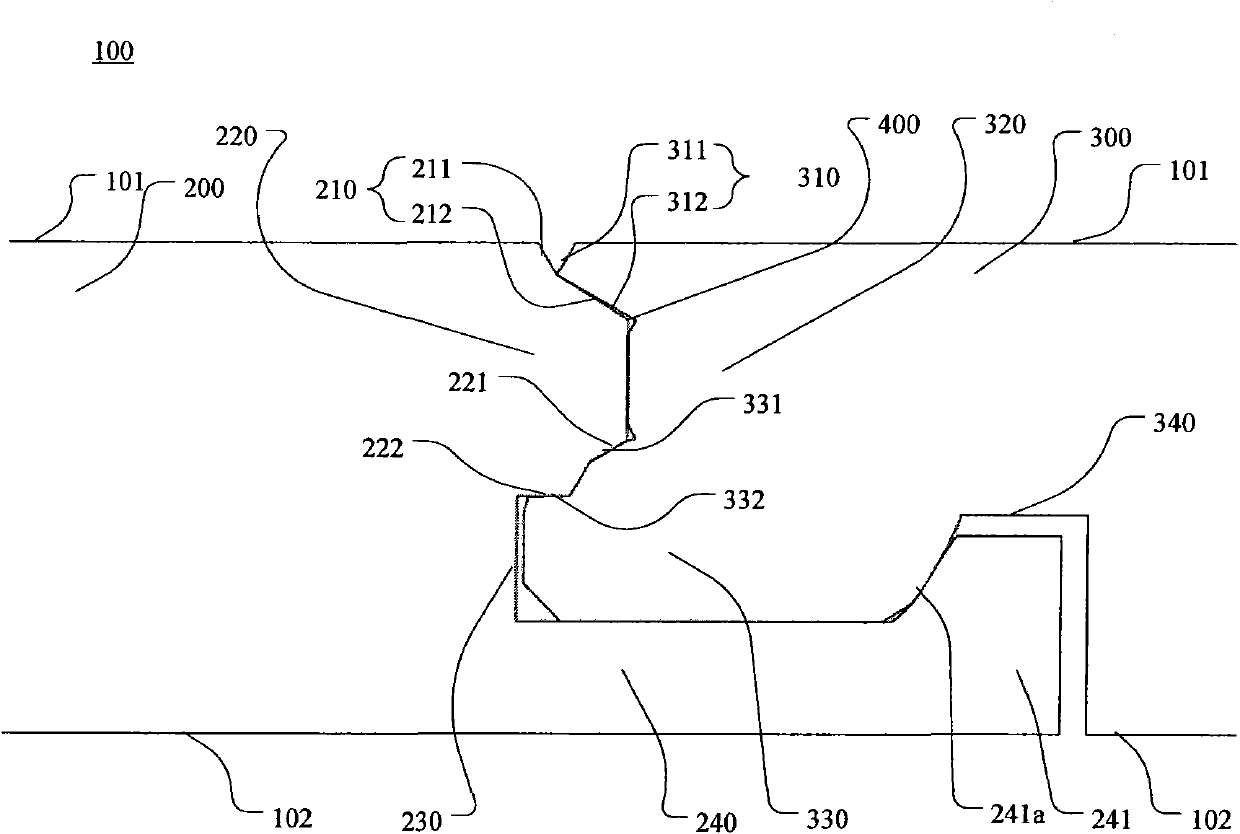

[0041] Such as image 3 As shown, a covered decorative board includes a board body 100 with a predetermined thickness, the upper surface of the board body 100 is a surface layer 101, the lower surface of the board body 100 is a bottom layer 102, and the board body 100 At least one edge is provided with an upward connecting portion 300, and the other edge opposite to this edge is provided with a downward connecting portion 200, and the two covering decorative panels can pass through the upward connecting portion 300 and the downward connecting portion 200. connected.

[0042]Wherein, the downward connecting portion 200 at least includes: a first slope 210, the first slope 210 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com