An electric field enhanced plate type falling film evaporation device and method thereof

A technology of falling film evaporation and strengthening plate, which is applied in the direction of chemical instruments and methods, evaporation, separation methods, etc., can solve the problems of low heat transfer coefficient, high heat transfer coefficient, large volume, etc., to improve heat transfer coefficient and reduce Energy consumption, the effect of increasing the effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

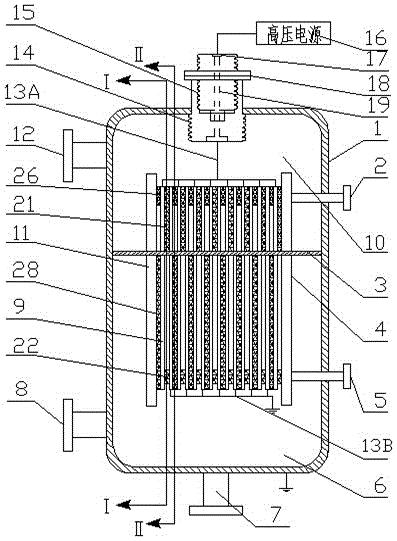

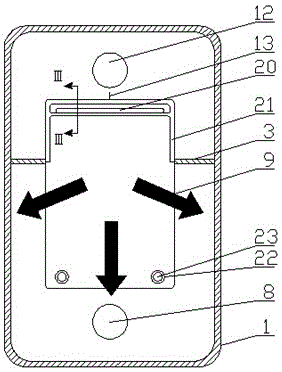

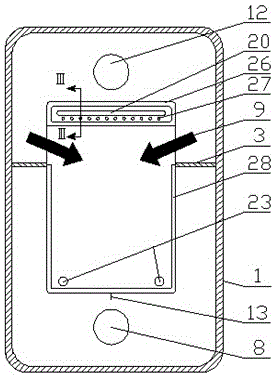

[0025] Such as figure 1 , 2 , 3, 4, the electric field-enhanced plate falling film evaporation device includes a housing 1, a liquid inlet 2, an insulating support partition 3, a plate falling film heat exchanger 4, a condensed water outlet 5, a gas-liquid separation space 6, a concentrated liquid Outlet 7, secondary steam outlet 8, stainless steel plate 9, inlet steam space 10, baffle 11, steam inlet 12, high voltage electrode wire 13A, ground electrode wire 13B, insulating base 14, PTFE spiral shell 15, High-voltage power supply 16, insulator 17, fastening ring 18, conductive rod 19, upper convex insulating sealing gasket 21, insulating sealing ring 22, liquid inlet insulating sealing gasket 26, lower convex insulating sealing gasket 28, condensation chamber 29, Evaporation chamber 30;

[0026] The shell 1 is provided with a plate falling film heat exchanger 4, and the insulating support partition 3 is fixed on the shell 1, and surrounds the plate falling film heat exchanger 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com