Novel control system of longitudinal cutting machine for glass production line

A technology of control system and slitting machine, which is applied in the direction of glass production, glass manufacturing equipment, glass cutting device, etc., can solve the problems of wasting plates, manpower consumption, poor precision, etc., and achieve the effect of saving plates and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

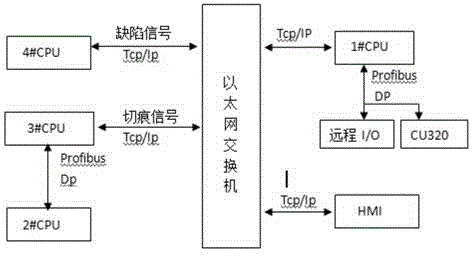

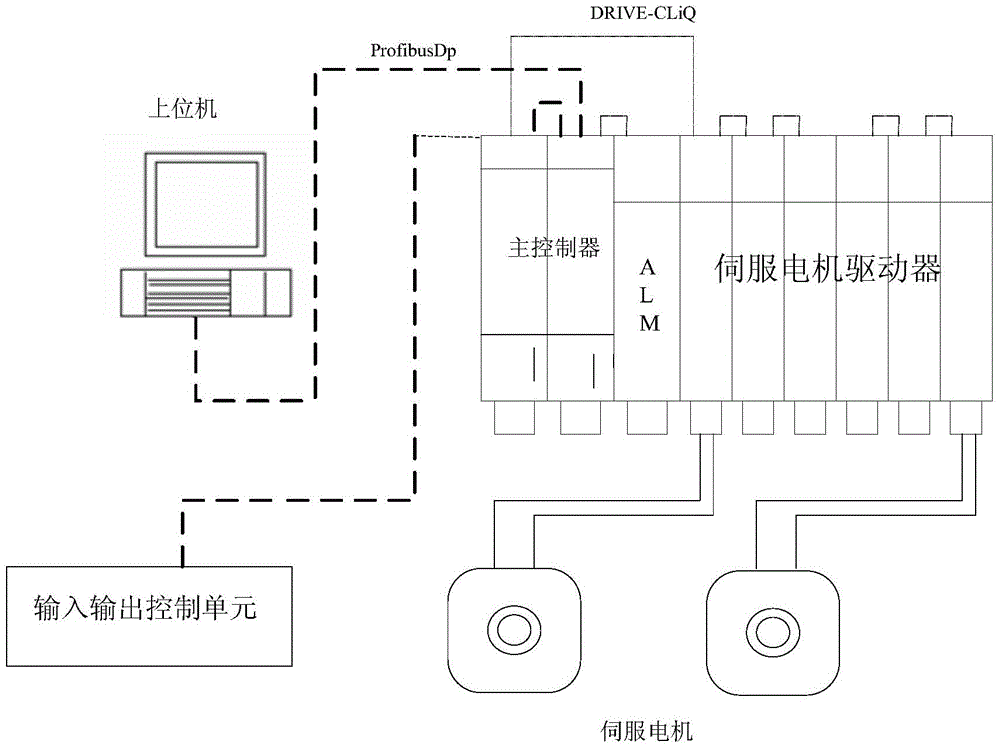

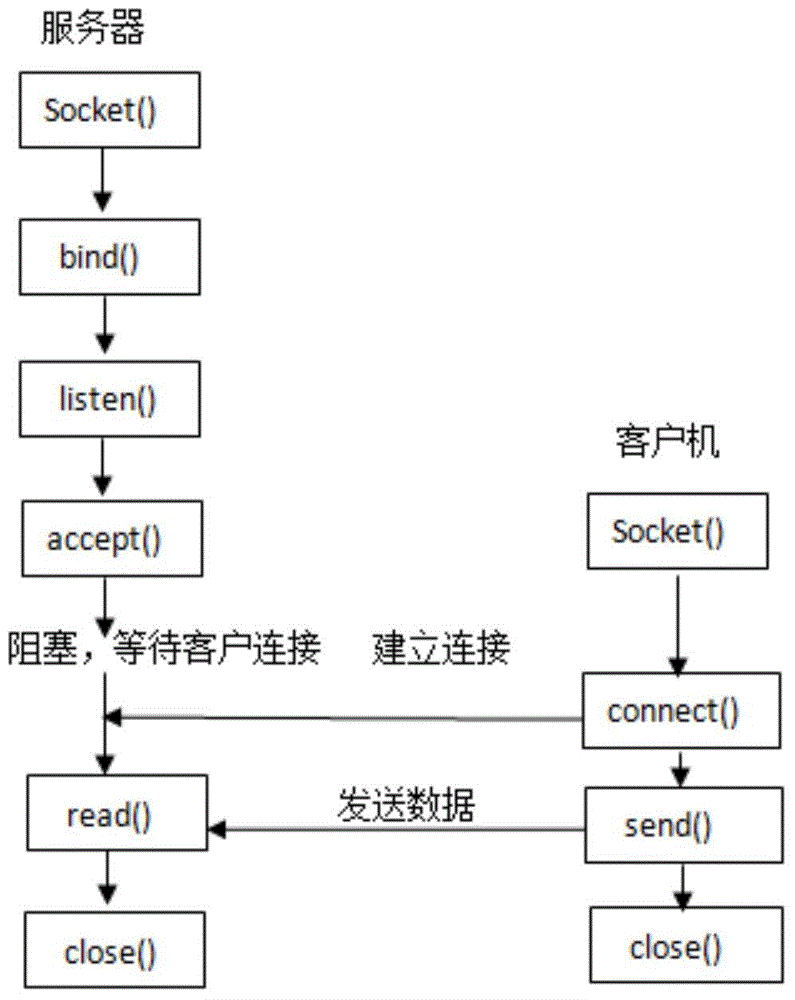

[0016] Such as figure 1 with figure 2 As shown, a new type of slitting machine control system, said slitting machine falling and refueling actions are controlled by relays, several knives are installed on said slitting machine, and the speed and position of said knives are controlled by servo motors, said The control system includes a main controller, and also includes a human-machine interface, a servo motor driver, and an input and output control unit. The input end of the main controller is connected to a host computer, and two-way communication is realized between the host computer and the main controller through industrial Ethernet. , the output end of the main controller is connected with a servo motor driver and an input and output control unit, and the main controller and the servo motor driver are connected to each other through a high-speed drive communication interface DRIVE-CLiQ, and the main controller and the input and output Two-way communication is realized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com