Elevator guide rail connecting structure and elevator

A connecting structure and elevator guide rail technology, which is applied in the field of elevators, can solve the problems of increasing rectangular connecting plates, consuming materials, increasing the configuration space of guide rail connections, etc., and achieves the effects of economical connection, saving plates, and reducing the thickness of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

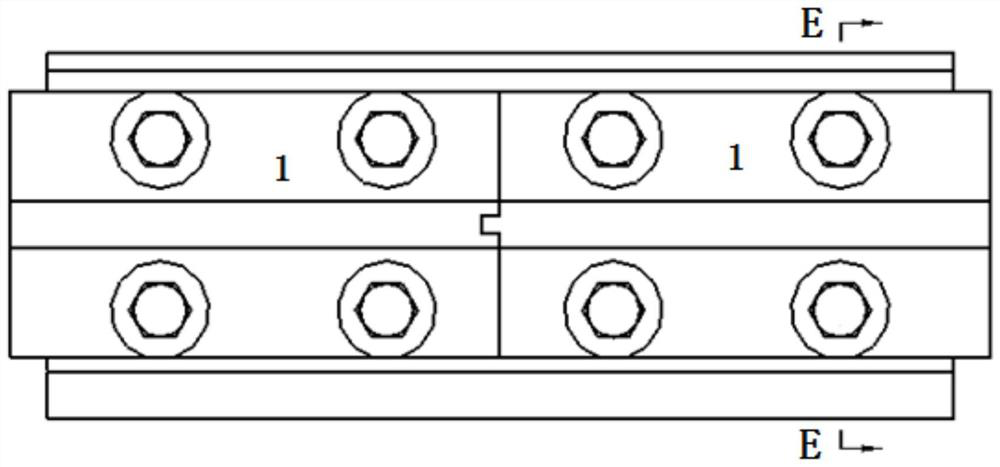

[0057] Such as Figure 1 to Figure 10 As shown, the elevator guide rail connection structure includes a guide rail 1 and a connecting plate 2;

[0058]The bottom surface of the guide rail 1 is T-shaped perpendicular to the guide surface;

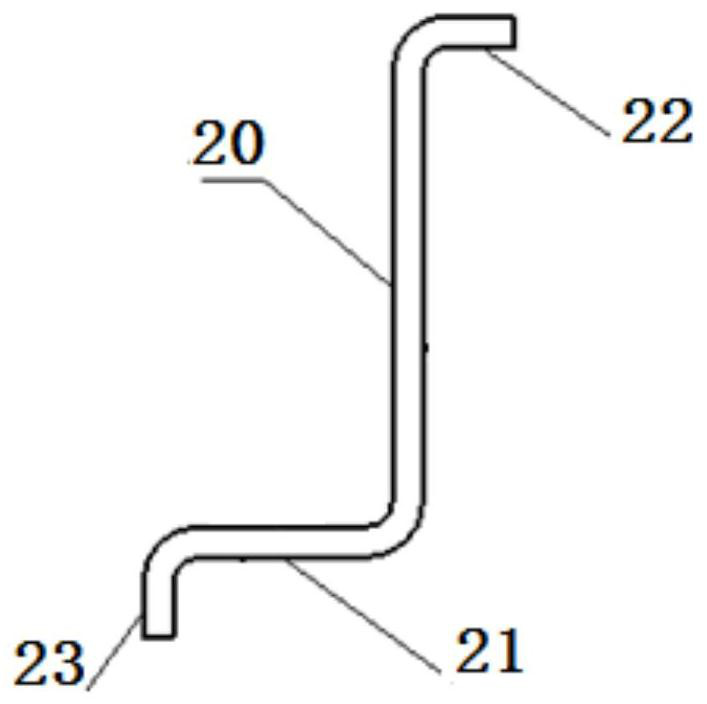

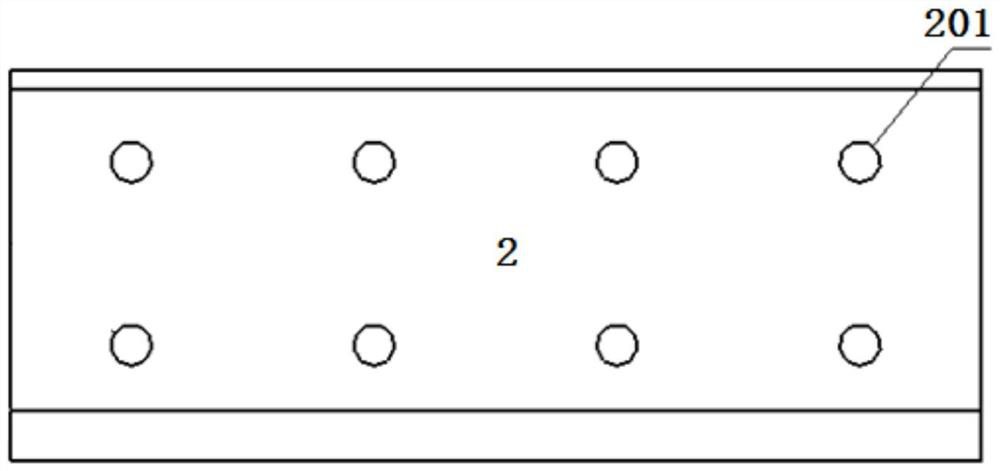

[0059] The connecting plate 2 is integrally formed, including a rectangular support portion 20 and a main reinforcing portion 21;

[0060] The main reinforcing part 21 is bent backward from the first end of the supporting part 20, and the first end is the left end or the right end;

[0061] The support portion 20 is vertically provided with a plurality of through holes 201;

[0062] Fasten the supporting part 20 of the connecting plate 2 with the bottom surfaces of the two docking rails 1 by bolts passing through the through holes 201 of the supporting parts 20 and the holes on the bottom surfaces of the two docking rails 1;

[0063] The front side of the support part 20 is attached to the bottom surface of the guide rail 1;

[0064] The...

Embodiment 2

[0068] Based on the connecting structure of elevator guide rails in Embodiment 1, the main reinforcing part 21 is rectangular, and the ratio of the length of the bolt at the rear side of the bottom surface of the guide rail 1 to the front and rear length of the main reinforcing part 21 is 0.5-1.1.

[0069] The elevator guide rail connection structure of the second embodiment is beneficial to reduce the occupied space of the elevator guide rail connection structure.

Embodiment 3

[0071] Based on the elevator guide rail connection structure of embodiment two, such as figure 1 , Figure 4 As shown, the connecting plate 2 also includes a main extension 23;

[0072] The main extension part 23 is parallel to the support part 20;

[0073] The main extension part 23 is bent from the rear end of the main reinforcing part 21 to the side away from the through hole.

[0074] Preferably, the main reinforcement part 21 is bent backwards from the first end of the support part 20 to form a 90° 0 ;

[0075] The main extension part 23 is bent at 90 degrees from the rear end of the main reinforcing part 21 to the side away from the through hole. 0 .

[0076] In the elevator guide rail connection structure of the third embodiment, the main extension part 23 of the connecting plate 2 is bent away from the surface of the main reinforcing part 21 and extends in a direction away from the through hole. The bending and forming of the main extension part 23 increases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com