Stamping mould for motor connector

A technology for stamping dies and connecting parts, which is applied in the field of stamping dies for motor connecting parts, can solve the problems of difficult to guarantee processing accuracy, low product qualification rate, low processing efficiency, etc., and achieves the effect of compact layout, improved qualification rate and plate saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

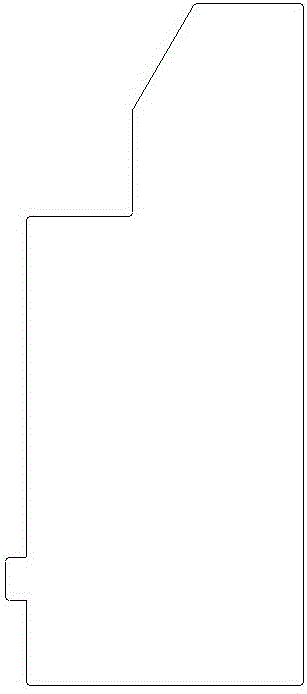

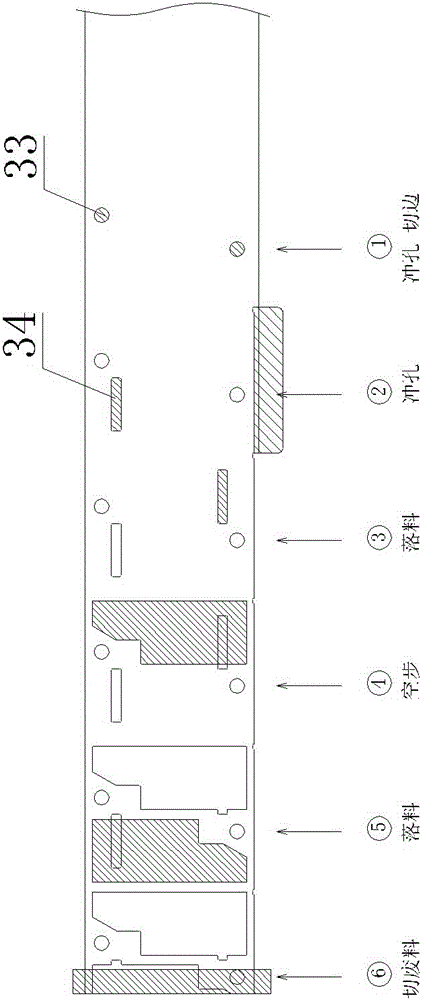

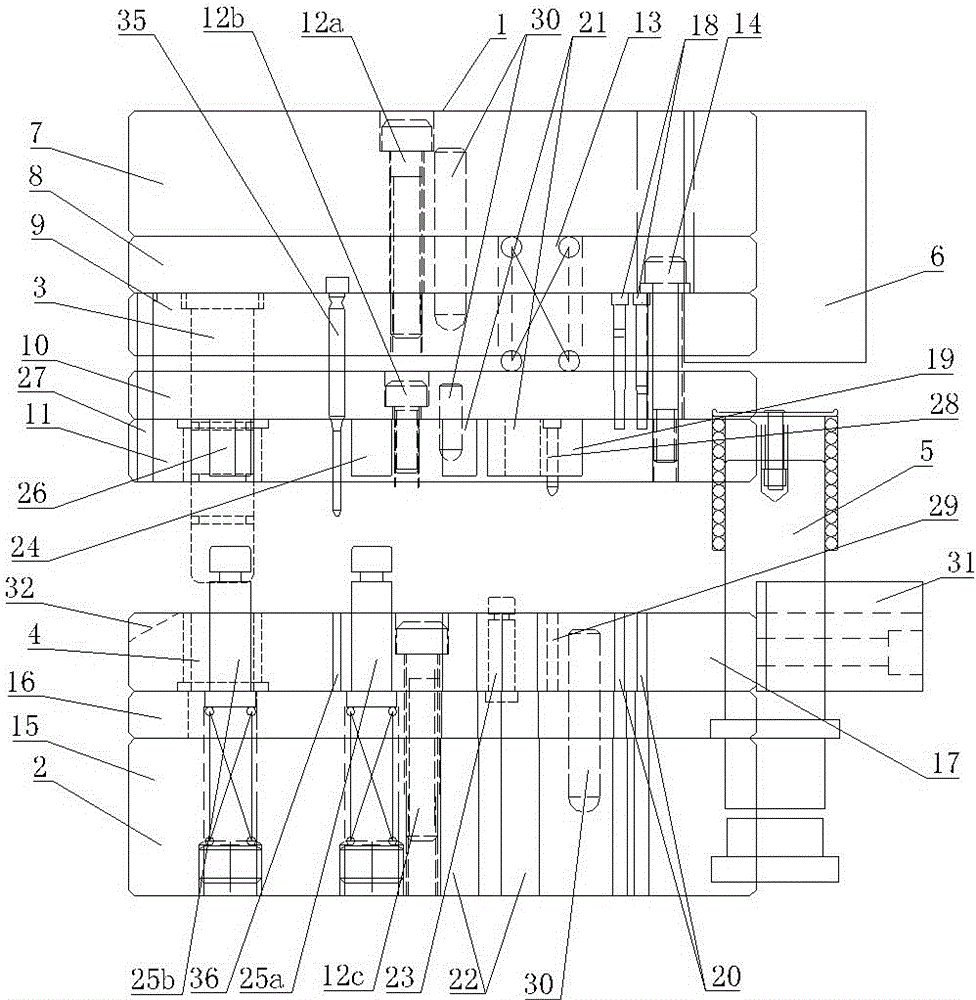

[0015] like figure 2 , image 3 As shown, the upper mold body 1 and the lower mold body 2 are included, and the upper mold body 1 and the lower mold body 2 are respectively guided by the inner guide post 3 and the inner guide sleeve 4, and the outer guide post 5 and the outer guide sleeve 6. The upper mold body 1 includes an upper mold base 7 and an upper backing plate 8, an upper splint 9, a stop plate 10 and a stripping plate 11 installed under the upper die base 7 in sequence, and the upper backing plate 8 and the upper splint 9 pass through The fixing bolt 12a is fixedly connected, and the stop plate 10 and the stripping plate 11 are fixedly connected by the fixing bolt 12b and installed under the upper clamping plate 9 by the spring 13 and the contour sleeve 14. The lower mold body 2 includes the lower mold base 15 and The lower backing plate 16 and the lower template 17 installed on the lower mold base 15 in sequence, the lower template 17 and the lower backing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com