Connecting structure for solid wood floor

A technology for connecting structures and solid wood floors, which is applied to building structures, floors, buildings, etc. It can solve the problems of easy moisture deformation, arching, high installation costs, waste of boards, etc., to achieve low installation costs, save boards, and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

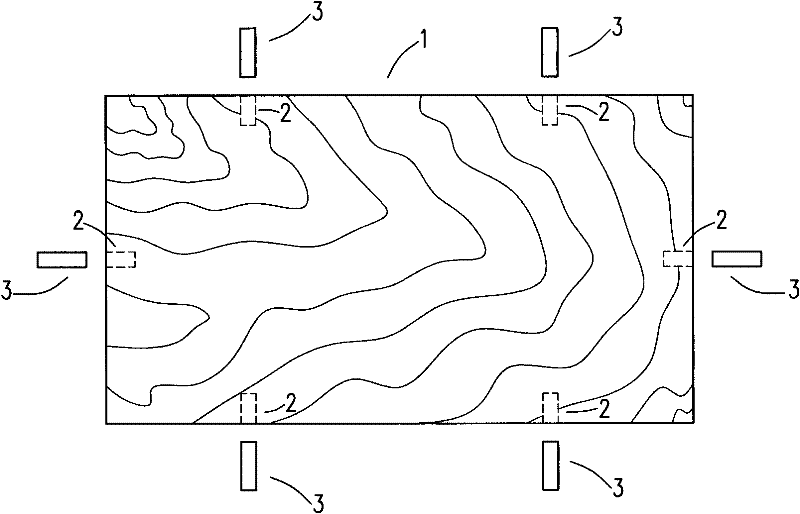

[0015] Such as Figure 1 to Figure 6 As shown, an embodiment of the present invention includes a wooden floor 1 , characterized in that: the wooden floor 1 is provided with tenon 2 on the end surface around it, and also includes a tenon post 3 matching the tenon 2 . The principle is: when installing the floor, it is not necessary to use a keel to fix it, and the adjacent wooden floors 1 are connected and positioned through the mortise 2 and the mortise post 3 arranged at corresponding positions.

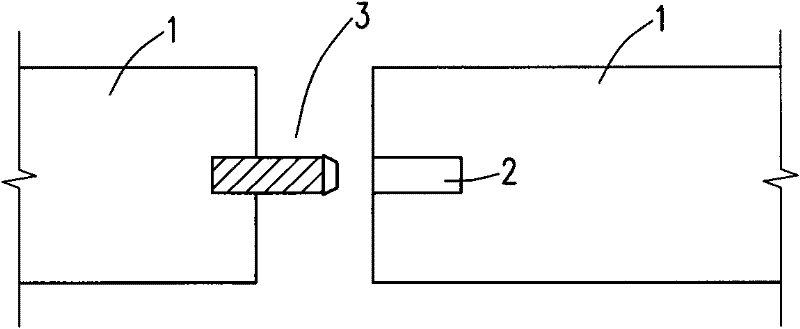

[0016] Such as figure 2 As shown, an improvement is that the tenon 2 is a blind hole, and the circumferential surface of the tenon post 3 is provided with fastening protrusions. The fastening emboss and the blind hole are an interference fit, and this connection structure is tighter and will not loosen during use. A preferred fastening relief is the use of threads.

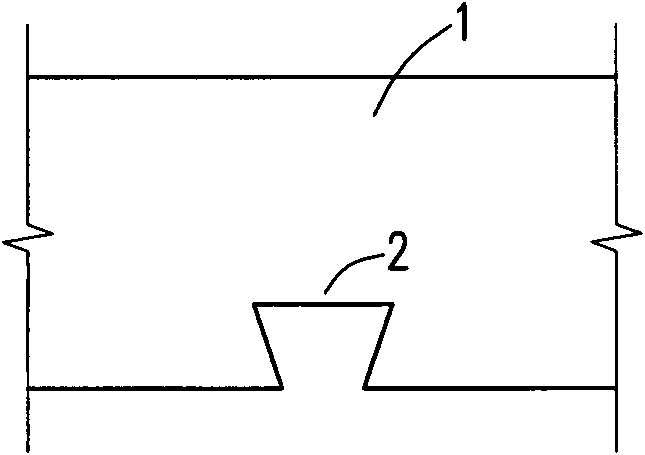

[0017] Such as image 3 As shown, the tenon 2 is a dovetail groove, and the tenon post 3 is a dovetail tenon post...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com