Lifting device of glass loading and unloading machine roller carrier

A technology of lifting device and roller frame, which is applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of unsteady lifting platform, glass quality influence, and difficult control of synchronization, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

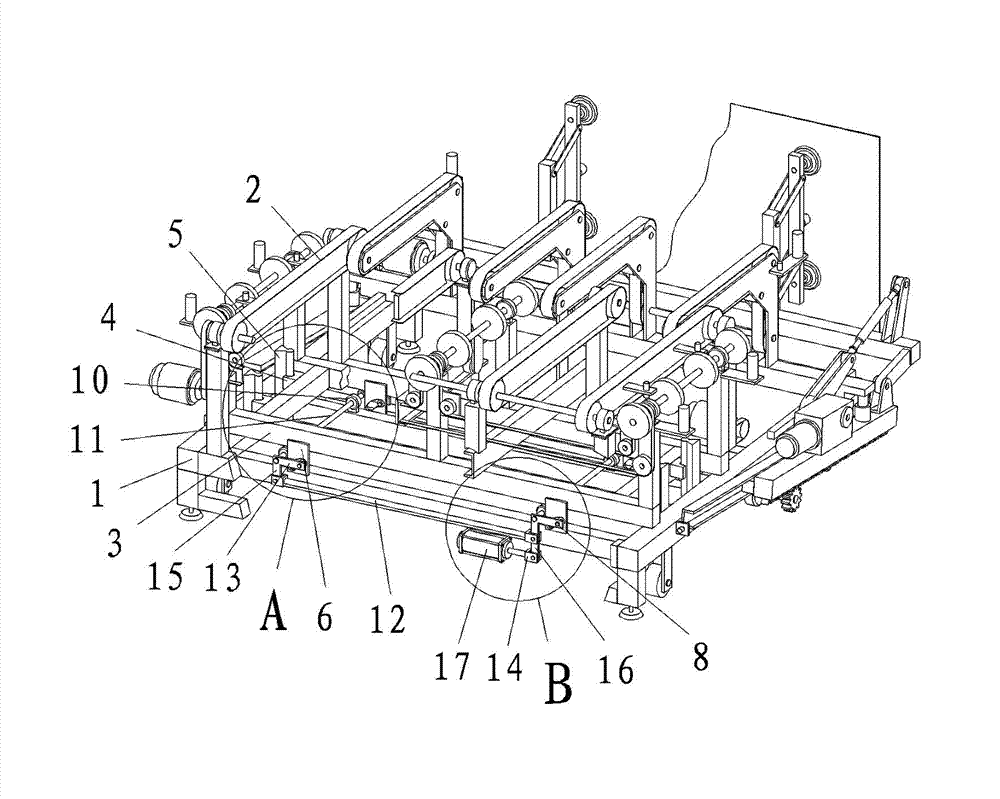

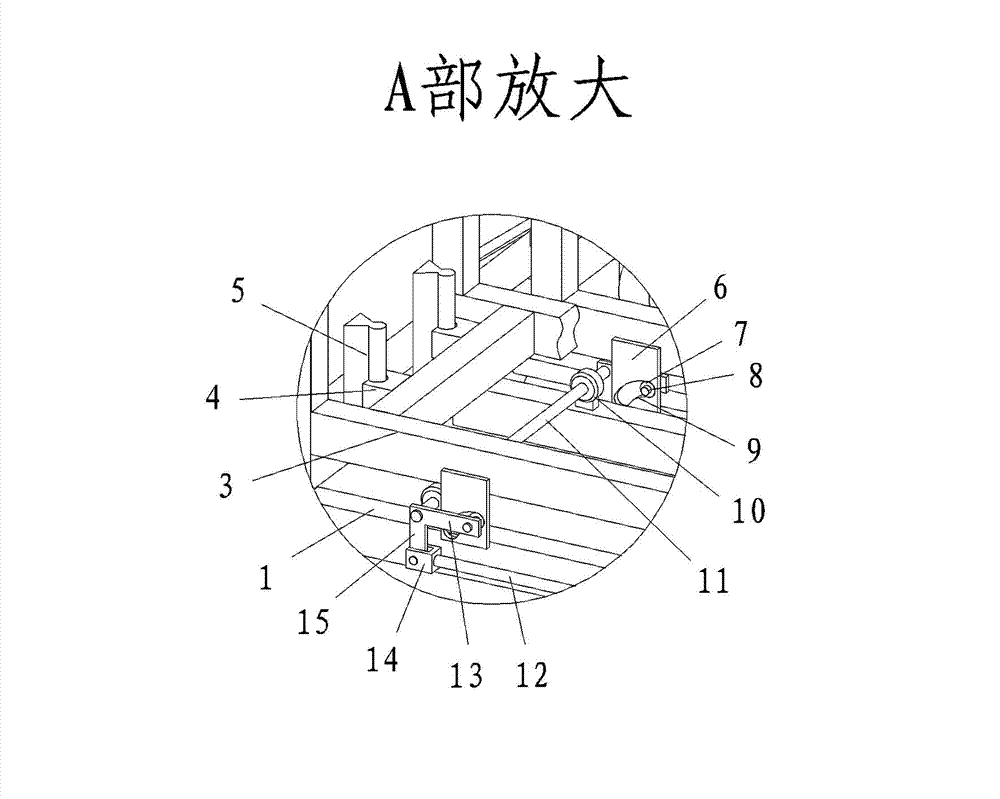

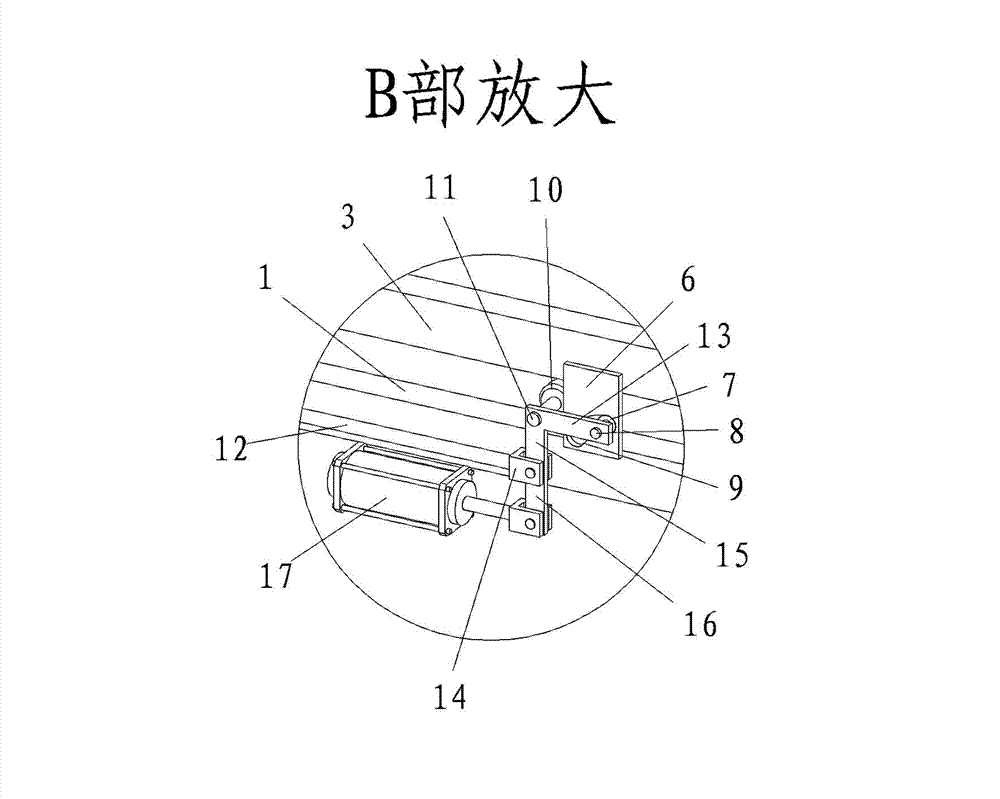

[0014] Depend on figure 1 , figure 2 , image 3 As shown, the lifting device of the roller frame of the glass loading and unloading machine includes a frame 1 and a fixed conveyor belt device 2 and a roller frame 3 arranged on it. It is characterized in that: the two sides below the roller frame 3 are provided with parallel rotating shafts 11, The both sides of rotating shaft are connected on the frame by bearing block 10, and the end of rotating shaft is provided with vertical bar 15, cross bar 13 respectively, and one end of vertical bar and cross bar is connected as a whole and fixedly connected with rotating shaft, between the vertical bar at two ends of rotating shaft Push-pull rods 12 are respectively arranged between them, and U-shaped hinged seats 14 are respectively arranged at both ends of the push-pull rods 12, and the hinged seat is hinged with the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com