Crank swinging feeding mechanism

A technology of feeding mechanism and crank is applied in the field of crank swing feeding mechanism, which can solve the problems of acceleration motor damage, loud noise, affecting the service life of the mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

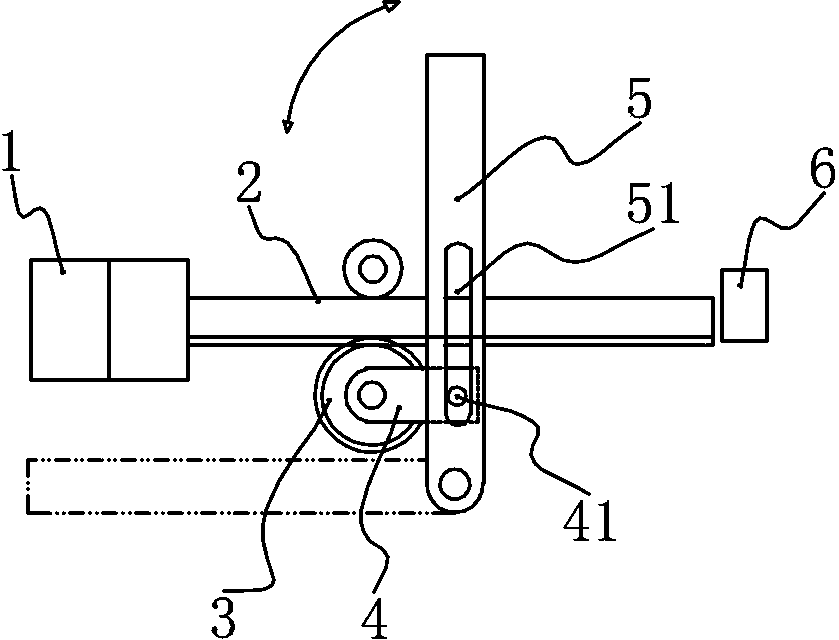

[0011] Such as figure 1 As shown, the crank swing feeding mechanism of the present invention includes a vertically arranged bracket, an electromagnet 1 is fixed on the bracket, the piston rod of the electromagnet 1 is fixedly connected to the rack 2, and the rack 2 is slidably connected to the bracket. A gear 3 is meshed on the tooth surface, and a connecting plate 4 is fixed on the gear 3 , and a transmission roller 41 is fixed on the free end of the connecting plate 4 . A fork 5 is also hinged on the support, and the middle section of the fork 5 is provided with a chute 51 , and the transmission roller 41 is inserted in the chute 51 . The stopper 6 that limits the movement of the rack 2 is also fixed on the support. By setting the stopper 6, the rack 2 can be prevented from falling out of the bracket under the action of inertia. The stopper 6 is provided with a pressure sensor, and the pressure sensor is connected to the control device of the electromagnet 1 through a proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com