Energy dissipation enhanced-type replaceable coupling beam

An enhanced and connecting beam technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of poor energy dissipation capacity and deformation capacity, and achieve strong energy dissipation capacity, easy disassembly and replacement, and dissipation of earthquake input energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

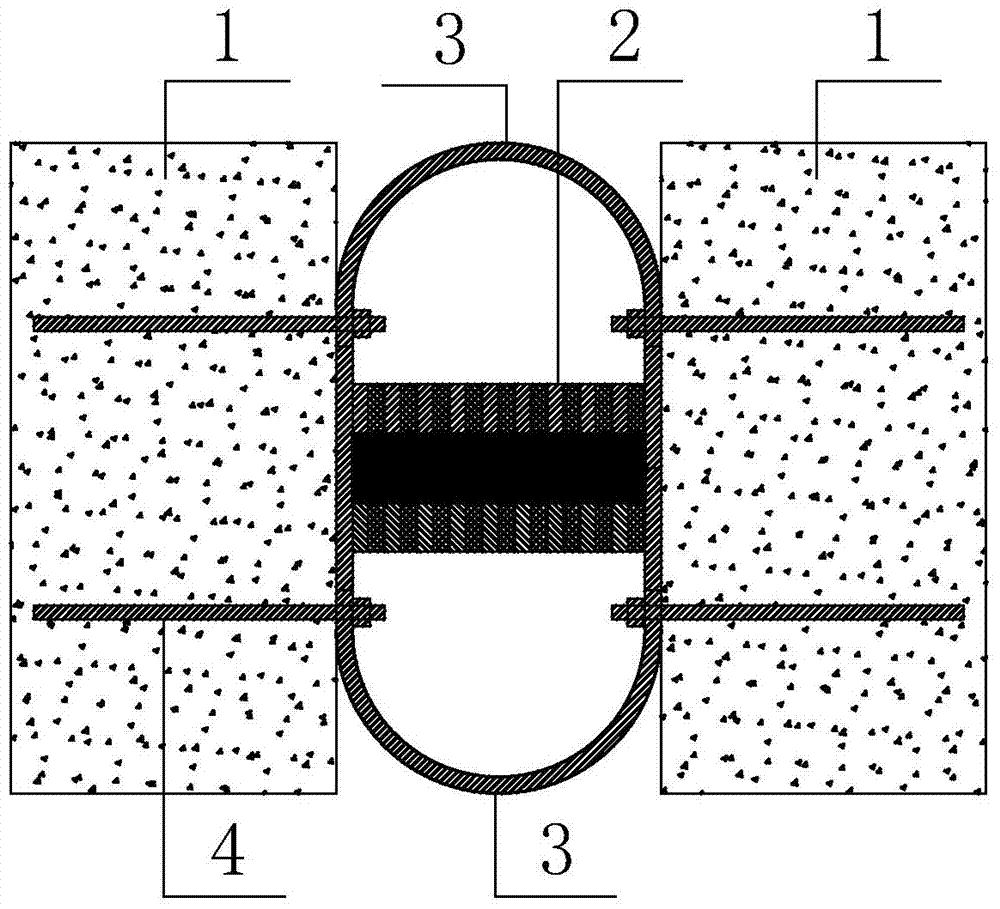

[0018] As shown in the accompanying drawings, the present invention is a replaceable coupling beam with enhanced energy consumption, which consists of a non-yielding section 1 and a replaceable section, the replaceable section is connected in parallel by a lead rubber damper 2 and two U-shaped steel plates 3 Composition, two U-shaped steel plates 3 are symmetrically arranged on the upper side and the lower side of the lead rubber damper 2 and fixed together with the end plate of the lead rubber damper 2 .

[0019] The U-shaped steel plate 3 is made of low yield point steel.

[0020] The U-shaped steel plate 3 does not yield during a small earthquake, but yields to dissipate the input energy of the earthquake during a moderate or large earthquake.

[0021] The replaceable section and the non-yielding section 1 are connected together by an embedded part 4 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com