Installation base of high-pressure oil pump of engine

A technology for high-pressure oil pumps and mounting bases, which is applied to engine components, machines/engines, and charging systems, and can solve problems such as unfavorable cylinder head production and transportation, complex installation and connection structures, and impact on cylinder head cover design, etc., to achieve a compact structure , Easy to install and disassemble, and avoid the effect of changing the shape of the engine cylinder head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

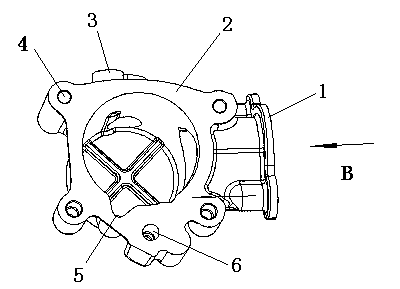

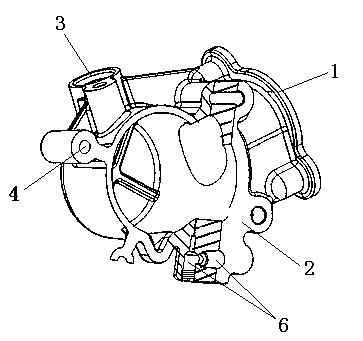

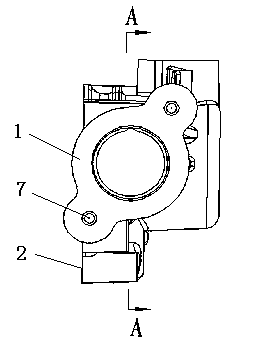

[0015] Such as figure 1 , figure 2 with image 3 As shown, the mounting base of the high-pressure oil pump of the engine is a two-way body with a 90° channel in the inner cavity. A first flange 2 and a second flange 1 are respectively arranged at both ends of the two-way body. Four flanges are opened on the first flange 2. Only one bolt passes through the hole 4, and two bolt holes 7 are provided on the second flange. A lubricating oil passage 6 is provided at the lower part of the first flange 2 of the two-way body. The oil inlet of the lubricating oil passage 6 is located at the lower part of the end face of the first flange 2, and its oil outlet is located on the inner wall of the two-way body. The diameter of the oil outlet is Like a pinhole, and upward toward the junction of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com