Balanced metal valve seat sealing structure for high-temperature high-pressure regulating ball valve

A high temperature and high pressure, metal valve seat technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as the inability of the valve to open, the deformation and failure of the graphite sealing ring, and the impact on the valve adjustment performance, so as to improve the performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and implementation methods.

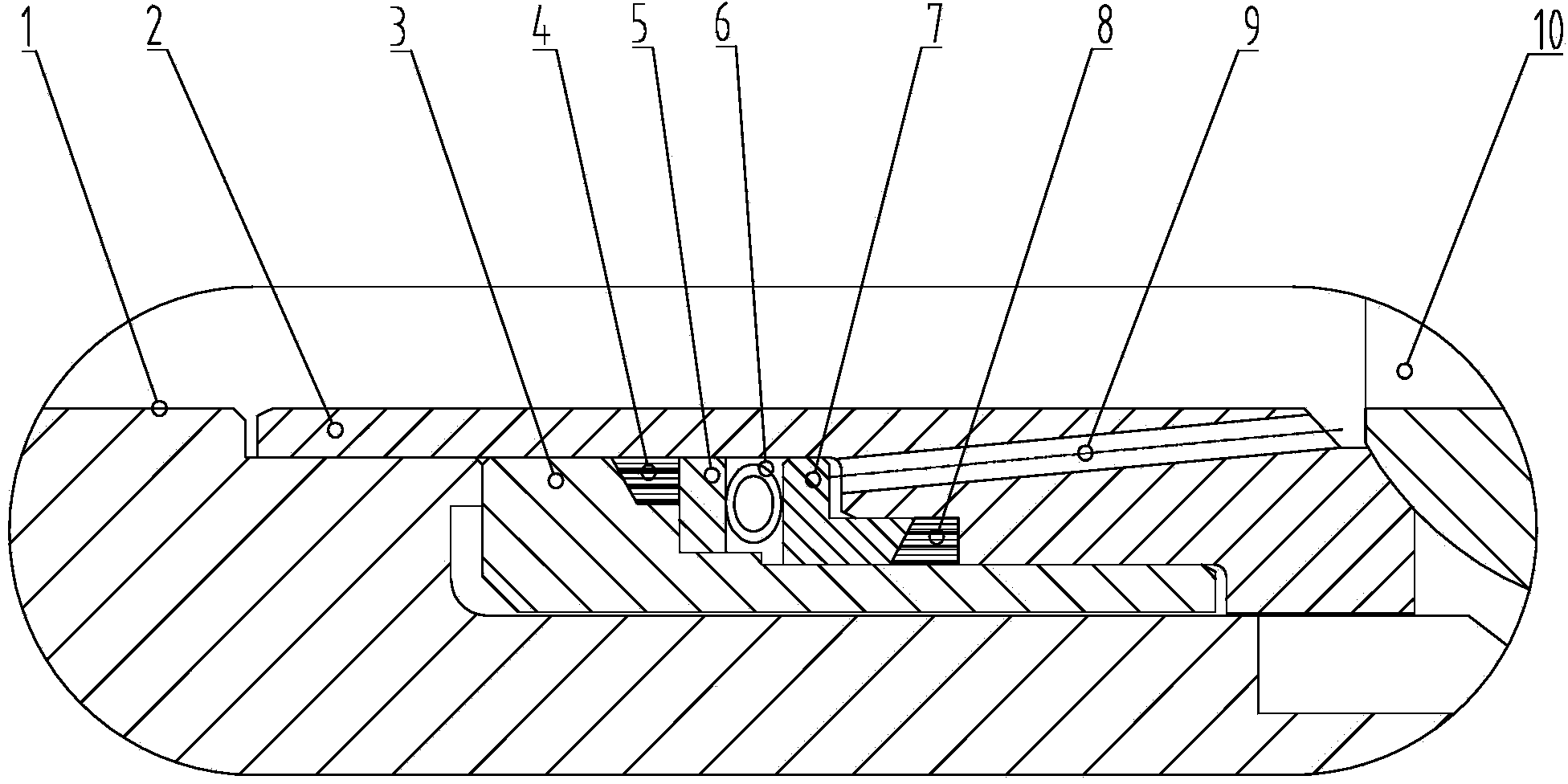

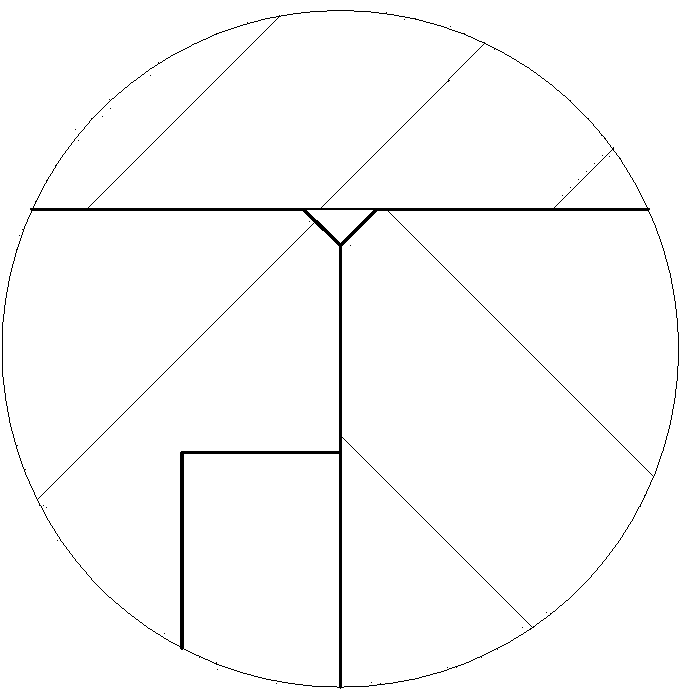

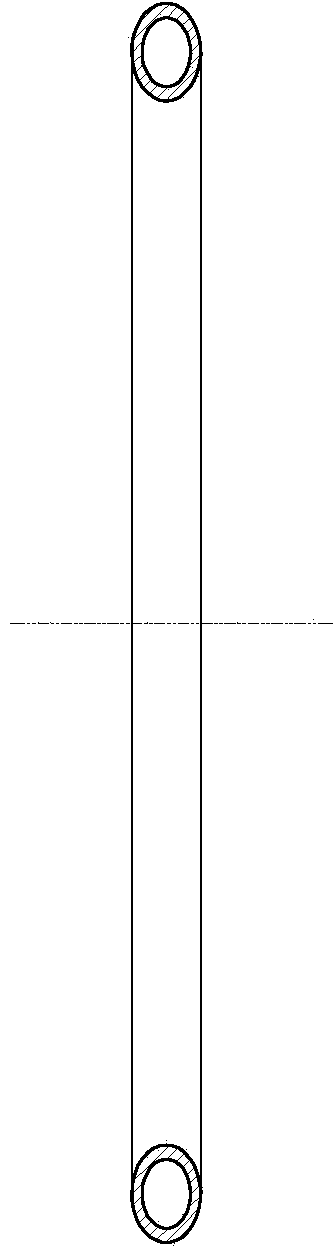

[0018] As shown in the figure: the high temperature and high pressure regulating ball valve balanced metal seat sealing structure includes valve body 1, valve seat 2, auxiliary valve seat 3, first metal graphite ring 4, thrust ring 5, metal O-ring 6, support ring 7 , The second metal graphite ring 8, balance hole 9, valve ball 10 and other components. The valve body 1 is connected with the valve seat 2, and the auxiliary valve seat 3 is installed in the valve body 1; the first metal graphite ring 4, the thrust ring 5, the metal O-ring 6, the support ring 7, the second The metal graphite ring 8 is sequentially installed between the auxiliary valve seat 3 and the valve seat 2; the metal O-ring 6 is installed between the thrust ring 5 and the support ring 7 to play the role of elastic compensation, and the balance valve seat 3 is close to the Ball 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com