Tool pedestal for detecting reference point through laser tracker

A laser tracker and detection benchmark technology, which is applied in the directions of measuring point marks, permanent markers, and landmarks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings, in order to explain its structure and working principle more clearly, but this cannot limit the protection scope of the present invention.

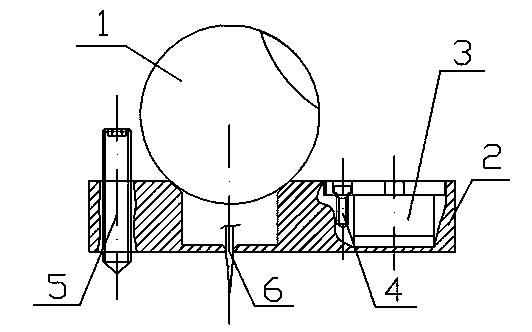

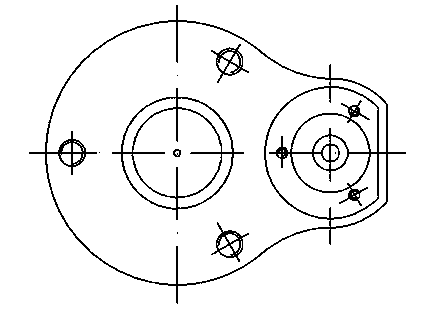

[0014] as attached Figure 1~2 As shown, the tooling base for the laser tracker of the present invention to detect the reference point includes a flat base 2, a universal level bubble 3, three leveling screws 5, a positioning needle 6 and a target reflective ball 1 , the universal vial 3 is fixed in the counterbore hole on the outer edge of the flat base 2 by fastening screws 4 . The flat plate base 2 is a metal plate placed horizontally. There is a cup-shaped cylindrical cavity on the metal plate. The upper edge of the cavity has a 45° chamfer. The target reflective ball 1 is placed on the cylindrical cavity, and the bottom of the cylindrical cavity is There is a reference point positioning hole at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com