Capacitive pressure sensor

A technology of capacitive sensors and pressure sensors, which is applied in fluid pressure measurement using capacitance changes, measuring fluid pressure through electromagnetic components, measuring fluid pressure, etc., can solve molding filling, insufficient filling, material demoulding, and excessive material overflow And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

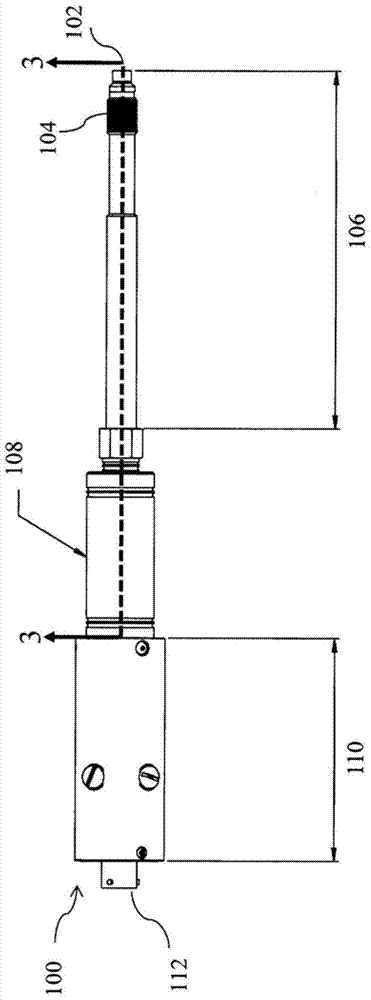

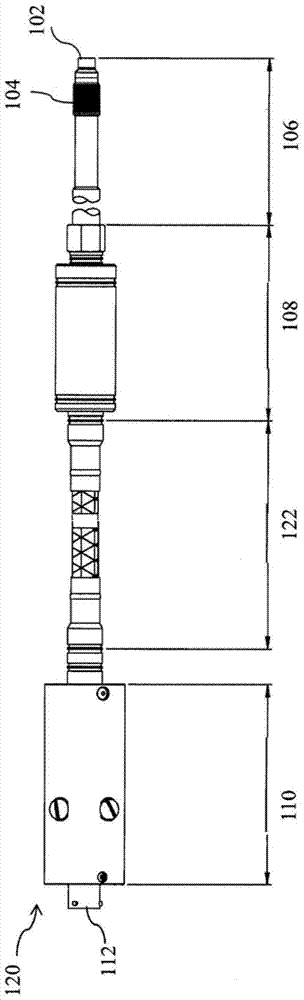

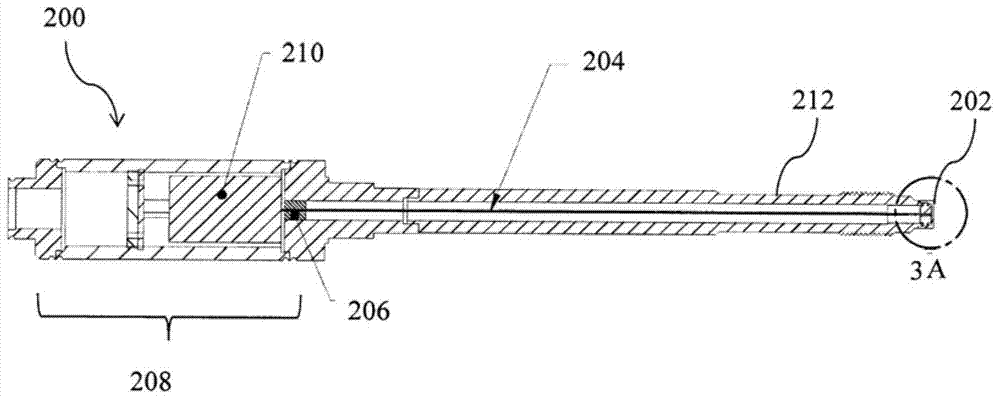

[0031] Pressure sensors used to monitor the pressure associated with polymer melts during extrusion and injection molding processes are subject to elevated temperatures ranging up to 400° C. or higher depending on the specific polymer. The inventors have realized that exposure to such a large temperature range not only requires correction of the output temperature signal due to high temperature effects, but that these temperatures also have an adverse effect on component life. Accordingly, the present inventors have recognized a need to provide a high temperature pressure sensor probe that is capable of accurately measuring pressure while also providing increased reliability and service life. Additionally, in order to provide a higher fidelity signal with greater sensitivity, the inventors have also realized that there is a need to reduce the overall signal loss and sources of interference within the pressure sensor. Additionally, the present inventors have recognized the need...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com