Automobile brake inspection bench capable of preventing wheels from deviating from simulated road surface

A technology for simulating road surface and automobile braking, which is applied in wheel testing, vehicle testing, machine/structural component testing, etc. It can solve problems such as easy deviation of wheels, affecting inspection efficiency, and cumbersome inspection process, and achieves convenient operation and improved performance. Inspection efficiency, effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

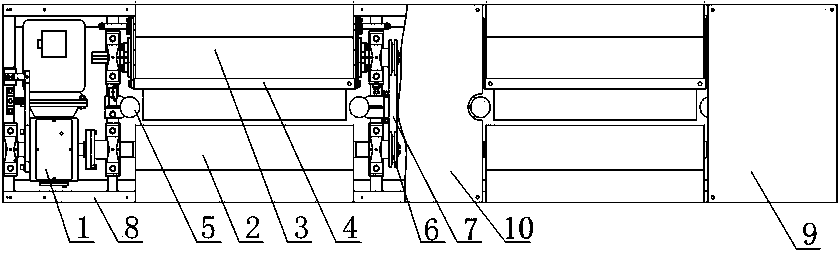

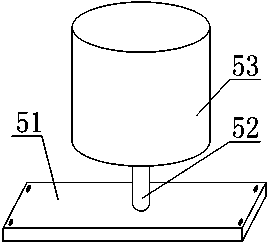

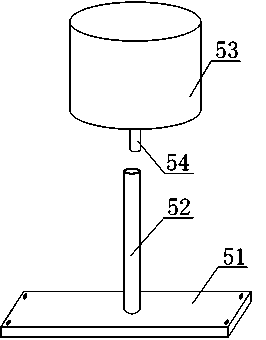

[0017] Such as figure 1 , figure 2 and image 3 As shown, the automobile brake inspection platform that can prevent the wheels from deviating from the simulated road surface includes a frame 8, and two groups of brake inspection devices on the left and right sides are arranged on the frame 8. The two groups of brake inspection devices all include a drive motor, a reduction box 1, The driving roller 2, the driven roller 3, the third roller 4, the torque box, the force measuring arm and the pressure sensor, wherein the driven roller 3 is placed parallel to the driving roller 2, and the two ends of the driven roller 3 are respectively connected to the driving roller 2. end aligned. The driving drum 2 and the driven drum 3 are all provided with a sprocket 6 at one end at the center of the frame 8, and the sprockets 6 of the driving drum 2 and the driven drum 3 in each group of brake inspection devices are connected by a roller chain 7, The other end of the driving drum 2 oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com