Method for fast predicting compressive strength of cement in 24 hours

A compressive strength, 24-hour technology, applied in the fields of civil engineering, construction industry, and hydraulic engineering, can solve problems such as low correlation, long cycle, and changing experimental conditions, and achieve the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: A certain brand of Portland cement P.II42.5R

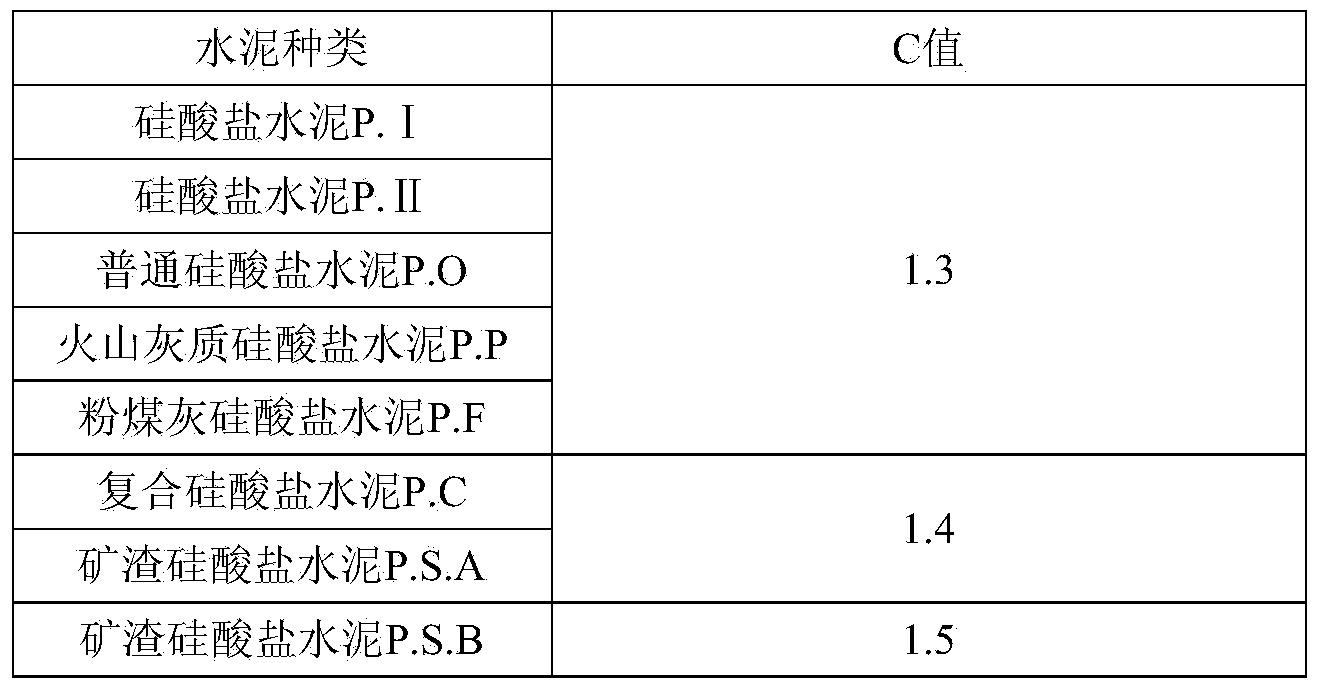

[0058] Look up Table 1 to determine that the cement C value is 1.3.

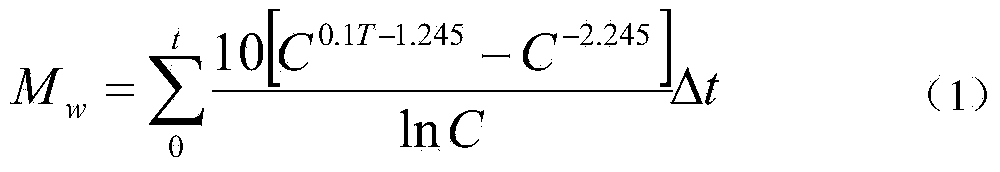

[0059] When placed in the humid heat curing box, the temperature is 20.7°C, and the calculated weight maturity and strength results are as follows:

[0060] Age 4h:

[0061] Age 5.5h: 1.5h is from 20.7°C to 55°C, this part is calculated according to the average temperature

[0062]

[0063] Age 9h: and 55 ℃ constant temperature time is 9h-0.5h-5.5h=3h

[0064]

[0065] The calculation is the same as the 9h age, except that the 55°C constant temperature time for other ages is different. The calculation results are as follows:

[0066] m w24h =1872.9℃.h

[0067] The 28-day weight maturity under 20°C standard maintenance is calculated as follows:

[0068]

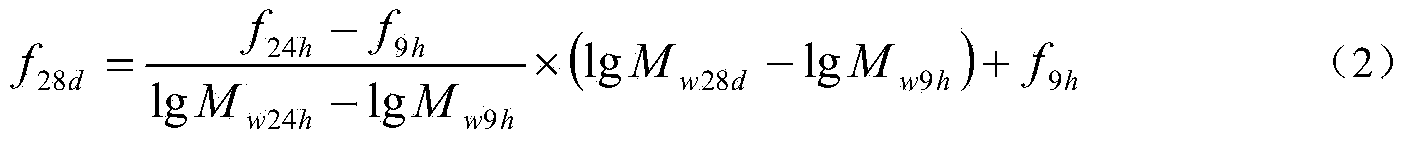

[0069] The predicted value can be obtained by substituting the compressive strength of cement mortar sand for 9h and 24h under humid heat curing into formula (2):

[0070] ...

Embodiment 2

[0074] Example 2: A certain brand of fly ash Portland cement P.F32.5

[0075] Look up Table 1 to determine that the cement C value is 1.3.

[0076] When placed in the humid heat curing box, the temperature is 21°C, and the calculated weight maturity results are as follows:

[0077] m 9h =479.7℃.h

[0078] m w24h =1873.4℃.h

[0079] m w28d =17012℃.h

[0080] The predicted value can be obtained by substituting the compressive strength of cement mortar sand for 9h and 24h under humid heat curing into formula (2):

[0081] f 28 d = 19.8 - 7.8 lg 1873.4 - lg 479.7 × ( lg 17012 - lg 479.7 ) + 7.8 = 40....

Embodiment 3

[0085] Example 3: A certain brand of slag portland cement P.S.A32.5

[0086] Look up Table 1 and determine that the C value of the cement is 1.4.

[0087] When placed in the humid heat curing box, the temperature is 20°C, and the calculated weight maturity results are as follows:

[0088] m 9h =523.5℃.h

[0089] m w24h =2137℃.h

[0090] m w28d =16364.7℃.h

[0091] The predicted value can be obtained by substituting the compressive strength of cement mortar sand for 9h and 24h under humid heat curing into formula (2):

[0092] f 28 d = 18.2 - 7.2 lg 2137 - lg 523.5 × ( lg 16364.7 - lg 523.5 ) + 7.2 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com