Method for preparing laminated battery cell

A laminated battery technology, which is applied in the manufacture of electrolyte batteries, circuits, electrical components, etc., can solve the problems of battery pole pieces that cannot be fixed and stack failures, and achieve the effect of firm fixation and easy loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

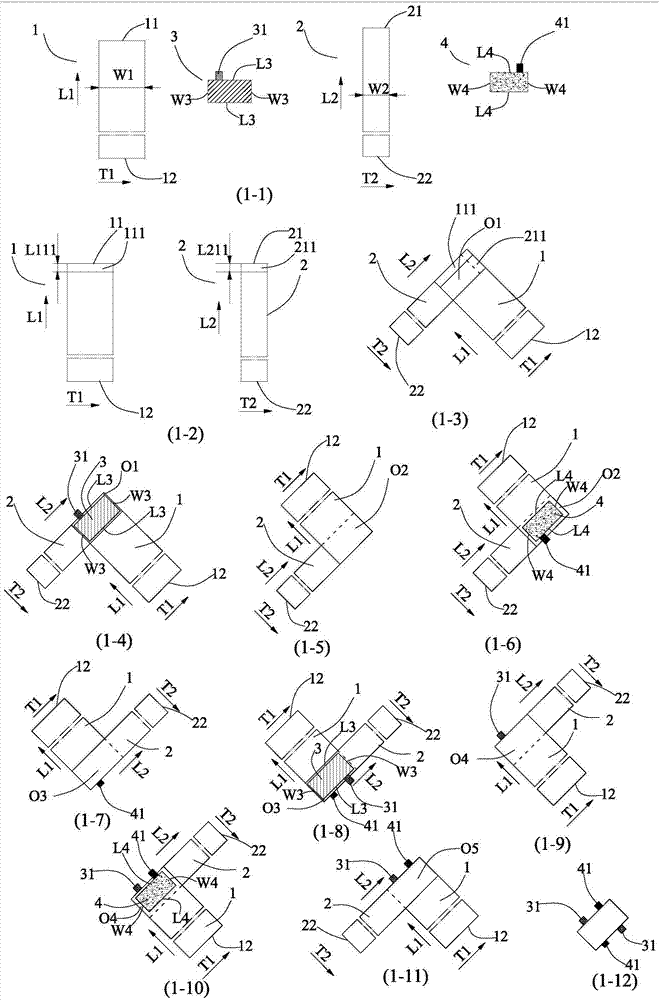

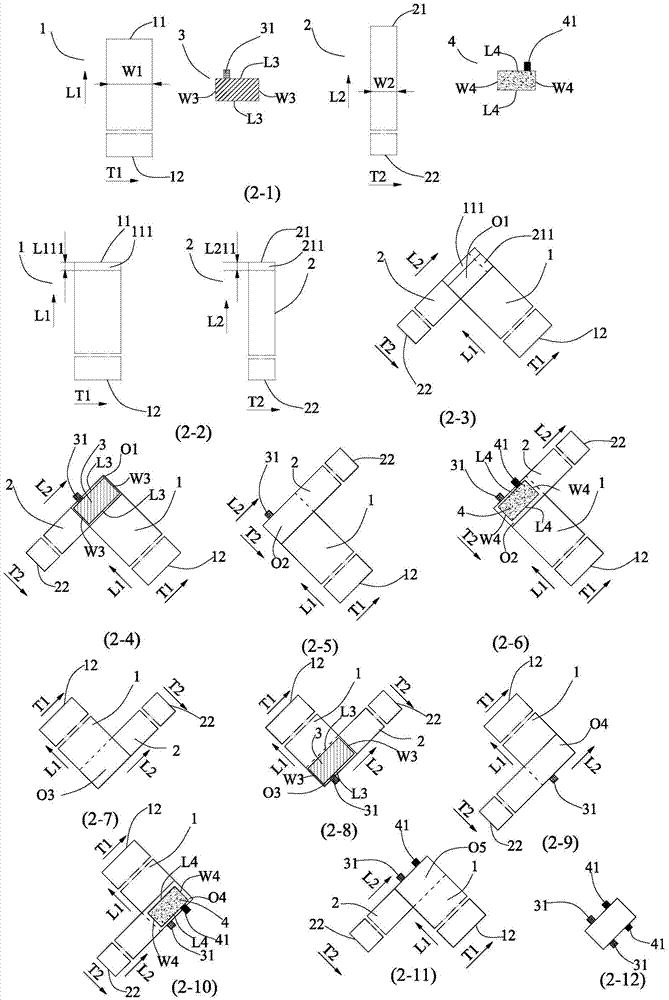

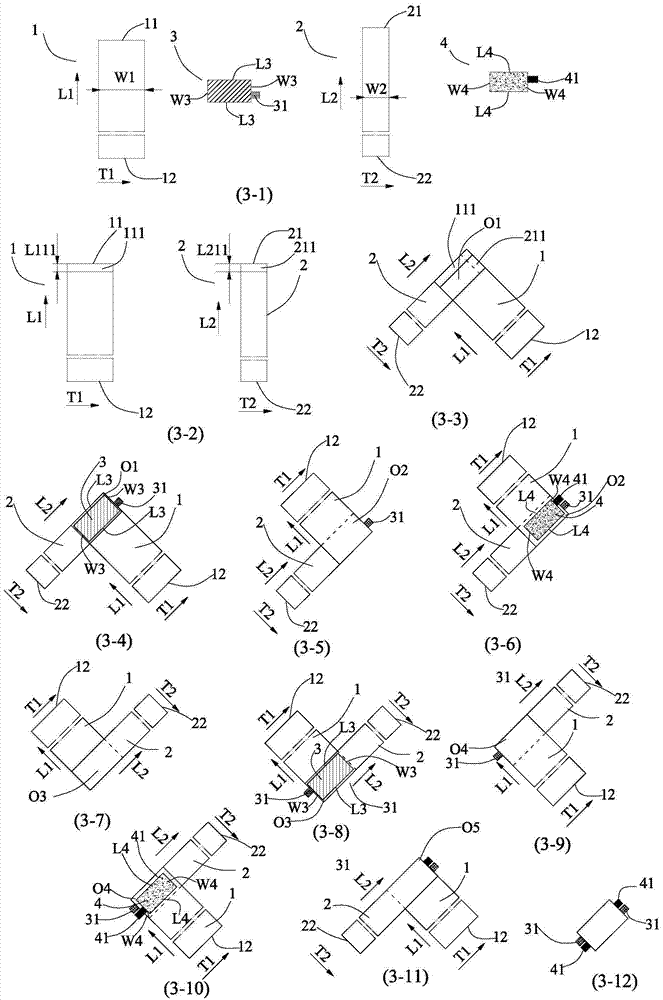

[0029] The preparation method of the laminated battery cell according to the present invention will be described in detail below with reference to the accompanying drawings.

[0030] refer to Figure 1 to Figure 6 , according to the preparation method of the laminated battery cell of the present invention comprises the steps of: preparing the first separator 1, the second separator 2 and the first pole piece 3 and the second pole piece 4 with opposite polarities, the first pole piece 3 It has a first tab lead-out end 31 and has a width side W3 and a length side L3. The second pole piece 4 has a second tab lead-out end 41 and has a width side W4 and a length side L4. The first separator 1 has a width side W3 and a length side L3. It has the opposite first head 11 and first tail 12, the width W1 of the first isolation film 1 in its transverse direction T1 is greater than the length side L3 of the first pole piece 3 and the length side L4 of the second pole piece 4, the first Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com