Printing method with metal luster

A printing method and metal texture technology, applied in the printing industry, can solve the problems of limited implementation methods, no ICC files, etc., and achieve the effect of huge cost advantage, less improvement, and high printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

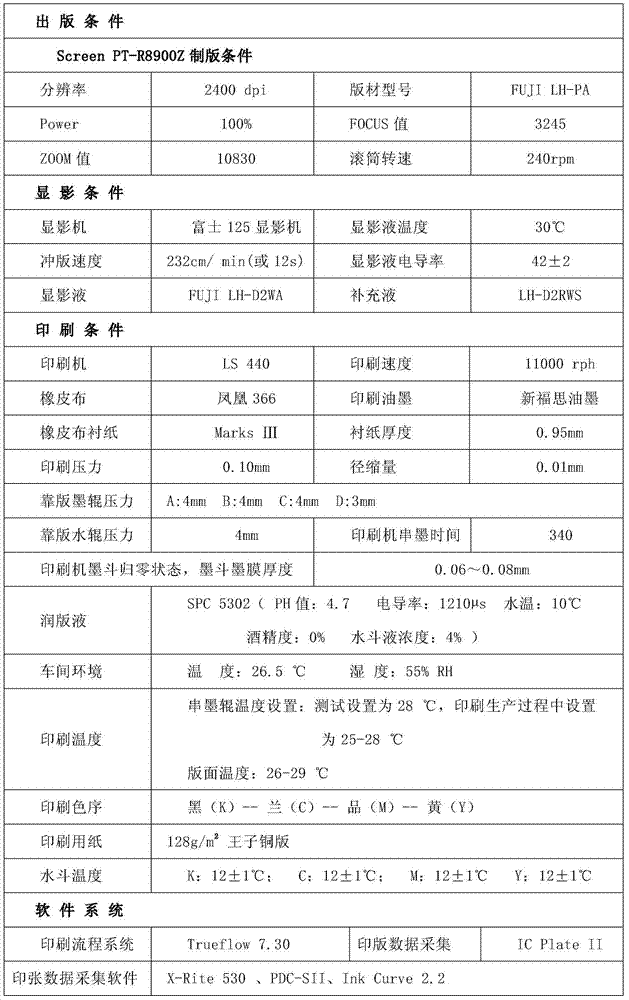

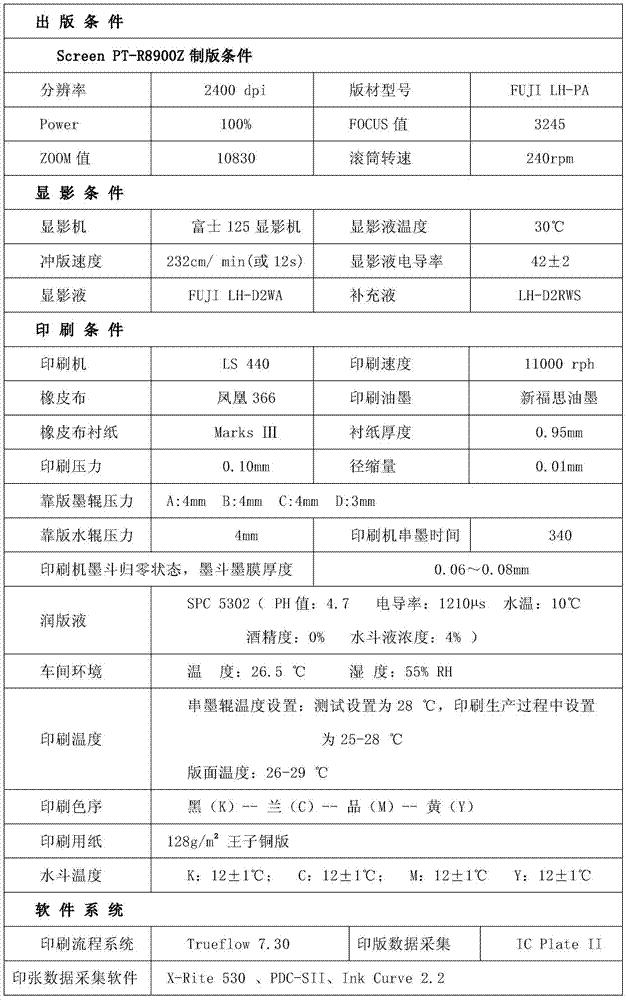

[0024] The manufacturing steps of the present invention are:

[0025] 1), standard color target design

[0026] In order to achieve the ideal metal printing effect in the present invention, the present invention first needs to design a suitable target color target. The traditional target color target has only four color targets, and the color information of the traditional four-color target color target only includes C\M\Y\K\ R\G\B\CMY these eight categories of color information. However, the present invention is 5-color printing, and a 5-color color target needs to be specially designed. The newly designed color target must include a color block printed with metallic color and other colors. The purpose is to obtain the matching relationship information between metallic color and other 4-color inks, and accurately grasp The characteristics of various metallic colors, the designed color targets include C\M\Y\K\R\G\B\CMY\metal+C\metal+M\metal+Y\metal+CMY\metal Color+K, a total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com