End wall structure and hopper car with same

A technology of hopper car and end wall, applied in the direction of hopper car, transport passenger car, railway car body parts, etc., to achieve the effect of increasing volume, increasing flexibility, and improving space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

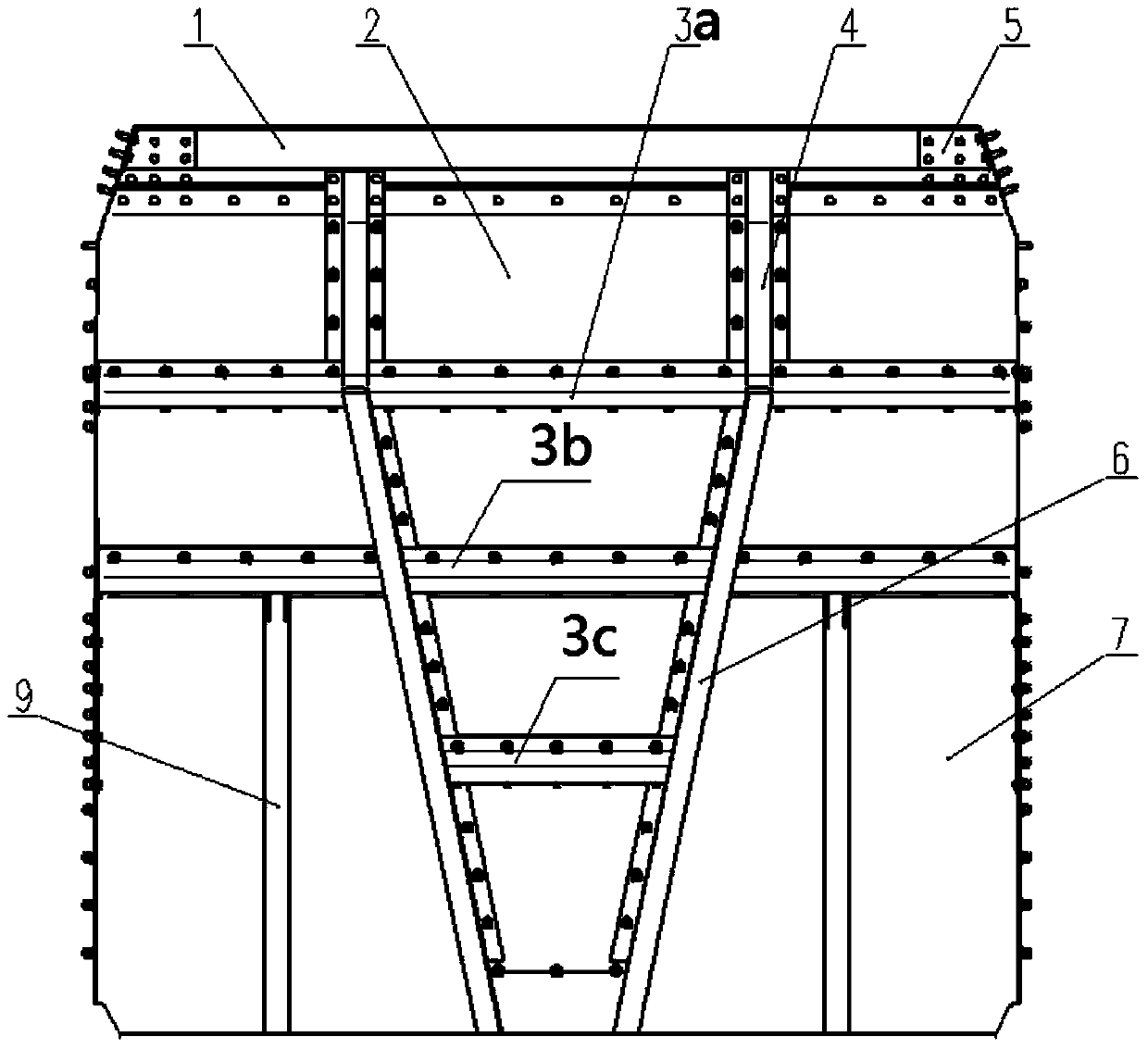

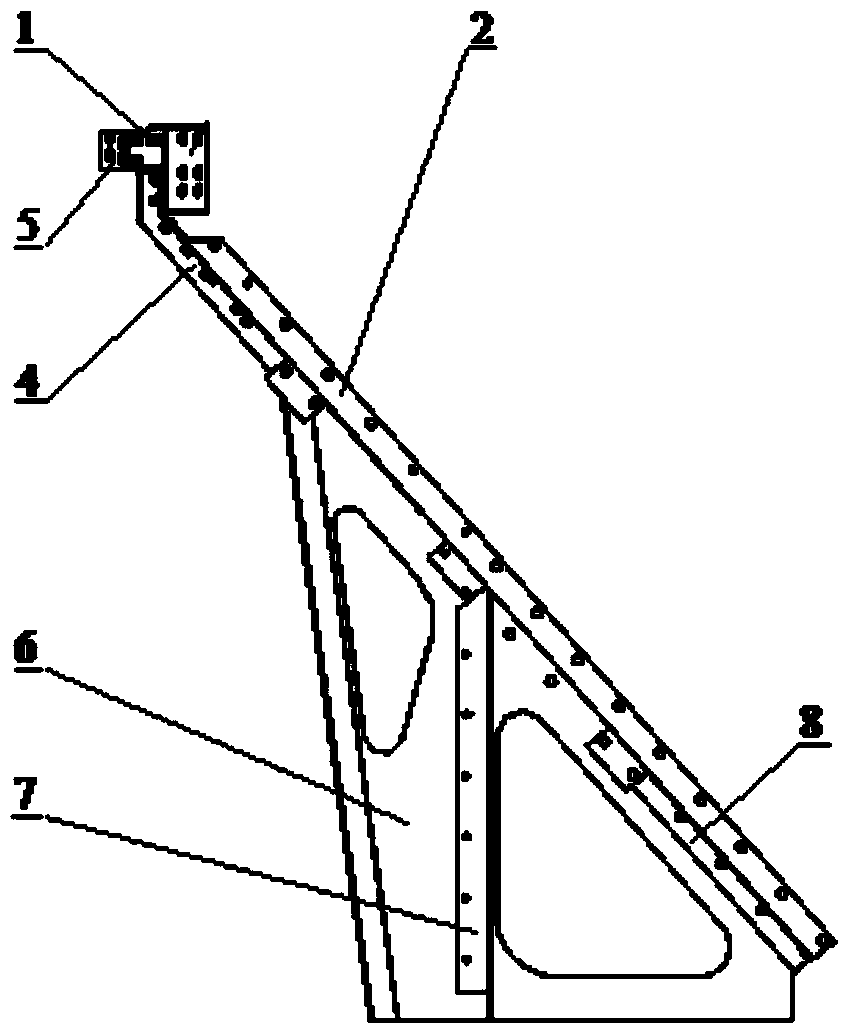

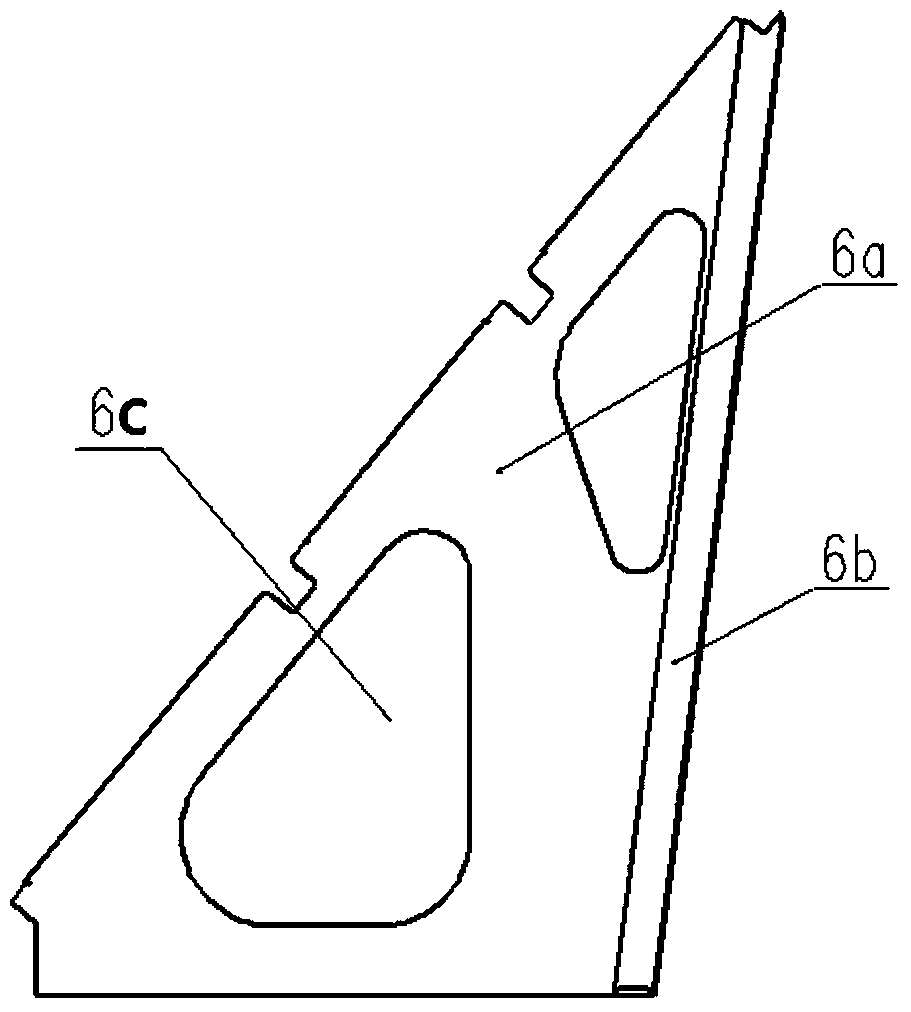

[0032] see Figure 1-8 As shown, the end wall structure of a hopper car provided by Embodiment 1 of the present invention includes a variable-angle end plate 2 with symmetrical folds (that is, the end plate 2 can be folded within a certain range of angle variation) and an upper end beam 1. On the back of the end plate 2, three horizontal belts 3 are evenly arranged by riveting from top to bottom. The end plate 2 is arranged at a variable angle to the horizontal plane (the angle can be varied within the range of 3-8 degrees, and the preferred variable angle is 5 degrees), and its upper end is connected with the upper end beam 1 in the form of riveting. The end plate 2 may be an integrally pressed end plate made of aluminum alloy. The material of the upper end beam 1 may also be an aluminum alloy profile. The upper end of the end plate 2 can be connected with the upper end beam 1 in the form of riveting. Between the upper end beam 1 and a horizontal belt 3a closest to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com