Water-saving reverse osmosis water purifier

A reverse osmosis water purifier, water-saving technology, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Large emissions and other issues, to achieve the effect that the service life will not be shortened, it will not be easily blocked, and the system will run stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

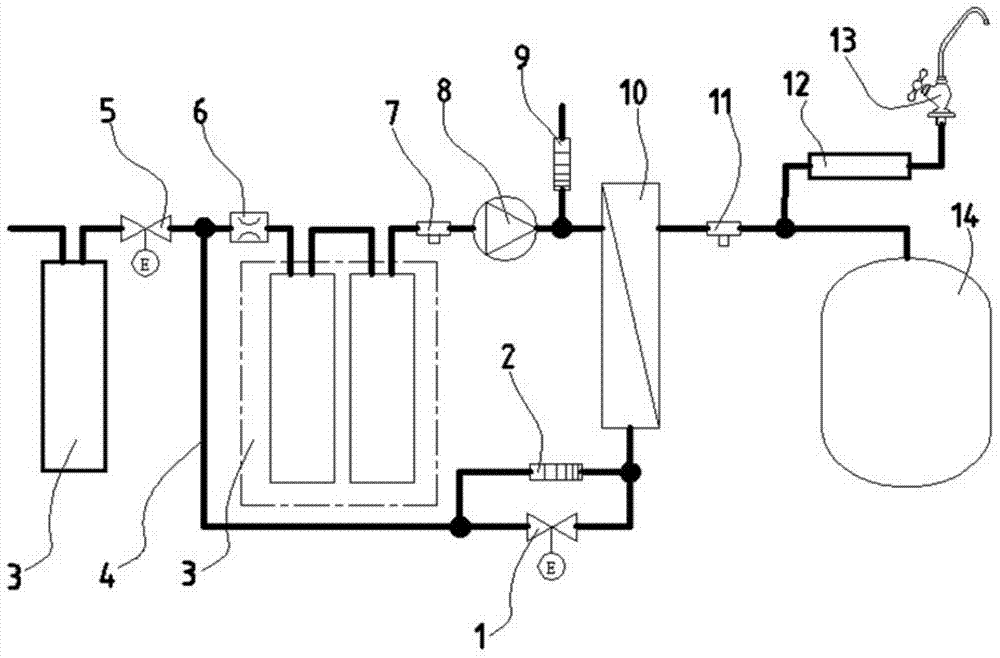

[0028] See figure 1 , the water-saving reverse osmosis water purifier of the present embodiment comprises a flushing valve 1, a large flow throttle valve 2, a pretreatment filter element 3, a return pipe 4, a water inlet valve 5, a water diverter 6, a low pressure switch 7, a booster Pump 8, small flow throttle valve 9, reverse osmosis processor 10, high pressure switch 11, rear activated carbon filter element 12, pure water outlet faucet 13 and pressure water storage tank 14.

[0029] The inlet of the pretreatment filter element 3 is connected to the water source, and the outlet thereof is connected to the inlet of the reverse osmosis processor 10 . The booster pump 8 is arranged in the water inlet pipeline of the reverse osmosis processor 10 . One end of the return pipe 4 is connected to the concentrated water outlet of the reverse osmosis processor 10 , and the other end is connected to the water inlet line of the booster pump 8 . The large flow throttle valve 2 is arrang...

Embodiment 2)

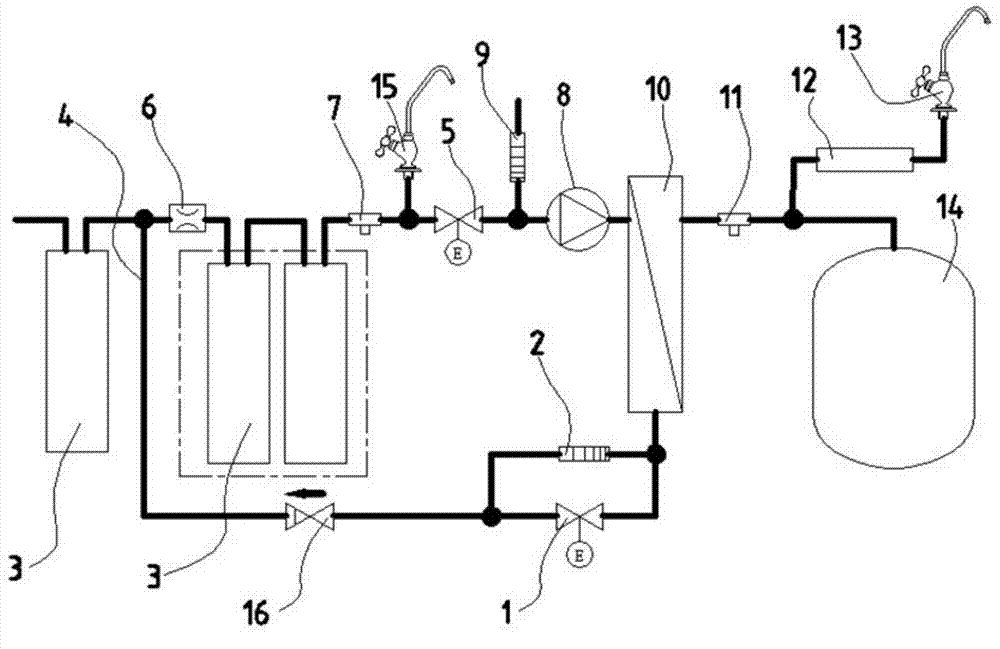

[0040] See figure 2 , this embodiment is basically the same as Embodiment 1, the difference is that: it also includes a water purification faucet 15.

[0041] The water inlet of the clean water outlet faucet 15 is connected with the water inlet of the water inlet valve 5 . The inlet of the water inlet valve 5 communicates with the outlet of the pretreatment filter element 3 . The return pipe 4 is provided with a one-way valve 16 . The direction of the one-way valve 16 is adapted to the direction of water flow in the return pipe 4 .

Embodiment 3)

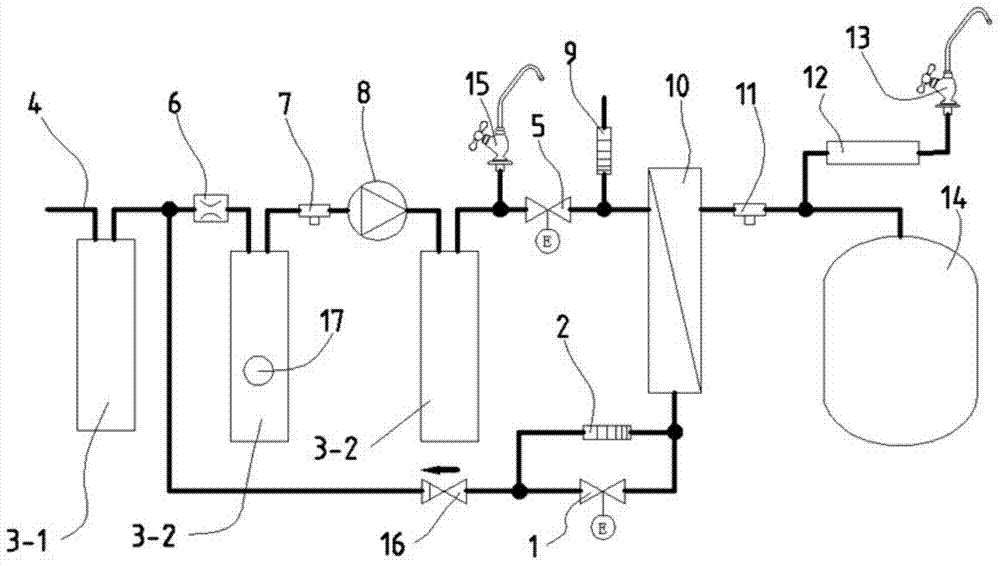

[0043] See image 3 , this embodiment is basically the same as Embodiment 1, the difference is that: it also includes a water purification faucet 15.

[0044] The water inlet of the clean water outlet faucet 15 is connected with the water inlet of the water inlet valve 5 . The pretreatment filter element 3 is provided with a solid sustained release agent 17 . The solid sustained release agent 17 includes compounds that can form complexes with calcium and magnesium ions in water after being dissolved in water. The solid sustained release agent 17 is an inorganic polymer phosphate. The pretreatment filter element 3 is composed of three stages of filter elements. One end of the return pipe 4 communicates with the water inlet or water outlet of the first-stage filter element. The booster pump 8 is arranged on the pipeline between the first-stage filter element and the second-stage filter element, or on the pipeline between the second-stage filter element and the third-stage fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap