A kind of continuous synthesis method of polyether

A synthesis method and polyether technology are applied in the field of continuous synthesis of polyethers prepared from small molecular alcohols as starting agents, and can solve problems such as wide molecular weight distribution of polyethers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

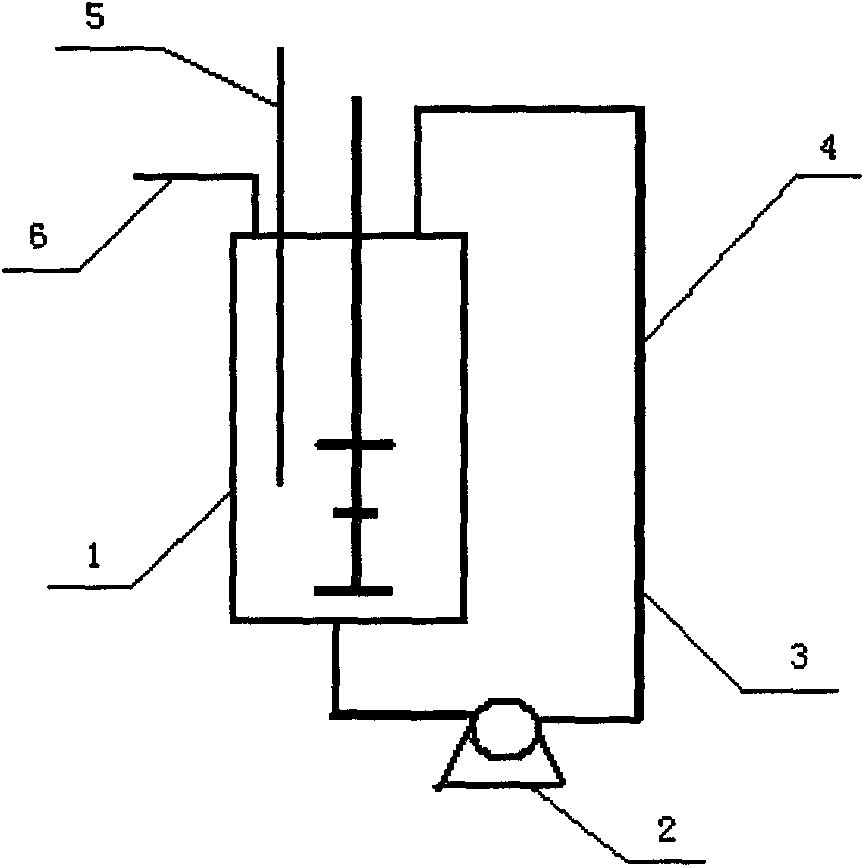

Method used

Image

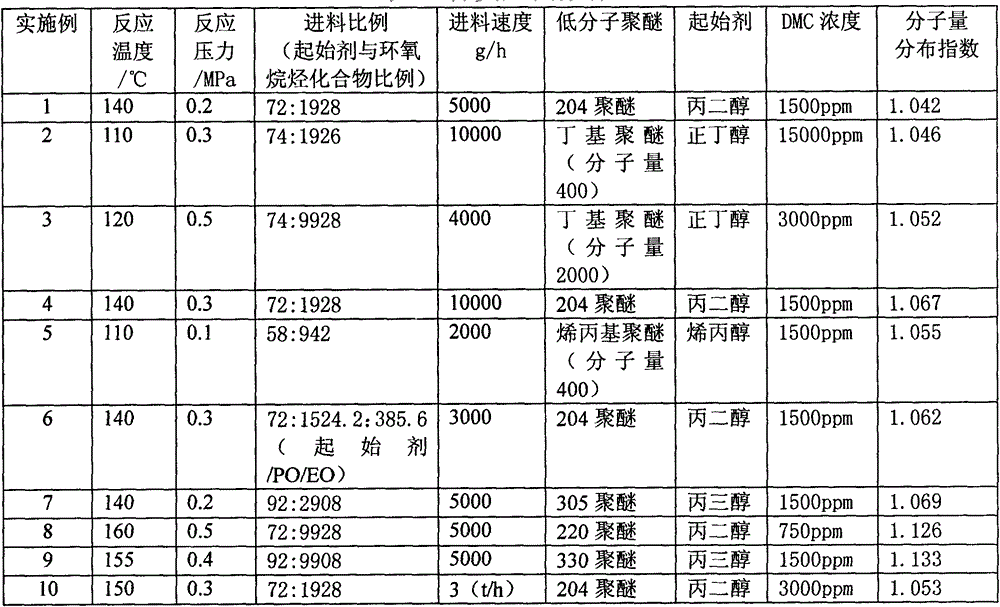

Examples

Embodiment 1

[0026] Add 600g of 204 polyether and 0.09g of DMC catalyst into a 5L reaction kettle with an external circulation feeding pipe, replace with nitrogen three times, vacuumize and raise the temperature to 130°C, then pressurize to 0.000MPa and feed 120g of propylene oxide until the pressure drops significantly 1. When the temperature rises rapidly, it indicates that the DMC catalyst has been induced, and when the pressure drops below 0.003MPa, it indicates that the induction is over. Keep the temperature of the reactor at 140° C., and then continuously feed 2280 g of propylene oxide. Then continuously add the mixture of propylene glycol and propylene oxide (propylene glycol / propylene oxide weight ratio=72: 1928) in the reactor with the speed of 5000g / h, simultaneously DMC catalyst and 220 polyether carrier (in terms of carrier DMC concentration is 1500ppm ) is added continuously through the external circulation pipeline at a speed of 100g / h. Keep the pressure of the reactor at 0...

Embodiment 2

[0028] Add 400g of butyl polyether (molecular weight: 400) and 0.06g of DMC catalyst to a 5L reaction kettle with an external circulation feeding pipe, replace with nitrogen three times, vacuumize and raise the temperature to 110°C, then pressurize to 0.000MPa and pass through 80g of ring Propylene oxide, when the pressure drops significantly and the temperature rises rapidly, it indicates that the DMC catalyst has been induced, and when the pressure drops below 0.003MPa, it indicates that the induction is over. Keep the temperature of the reactor at 110° C., and then continuously feed 1520 g of propylene oxide. Then add the mixture of n-butanol and propylene oxide (n-butanol / propylene oxide=74: 1926) continuously in the reactor with the speed of 10000g / h, simultaneously DMC catalyst and butyl polyether (molecular weight 2000) carrier ( DMC concentration (15000ppm in terms of carrier) is continuously added through the external circulation pipeline at a speed of 20g / h. Keep th...

Embodiment 3

[0030] Add 600g of butyl polyether (molecular weight: 2000) and 0.09g of DMC catalyst to a 5L reaction kettle with an external circulation feeding pipe, replace with nitrogen three times, vacuumize and raise the temperature to 120°C, then pressurize to 0.000MPa and pass through a 120g ring Propylene oxide, when the pressure drops significantly and the temperature rises rapidly, it indicates that the DMC catalyst has been induced, and when the pressure drops below 0.003MPa, it indicates that the induction is over. Keep the temperature of the reactor at 120° C., and then continuously feed 2280 g of propylene oxide. Then add the mixture of n-butanol and propylene oxide (n-butanol / propylene oxide=74:9928.4) continuously in the reactor with the speed of 4000g / h, simultaneously DMC catalyst and butyl polyether (molecular weight 2000) carrier ( DMC concentration (3000ppm in terms of carrier) is continuously added through the external circulation pipeline at a speed of 40g / h. Keep th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com