Direct-draining type sewer floor drain with three cavities

A technology of sub-cavities and floor drains, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve problems that cannot meet modern life, and achieve the effects of eliminating dirt and clogging, eliminating channel blockage, and reducing drainage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

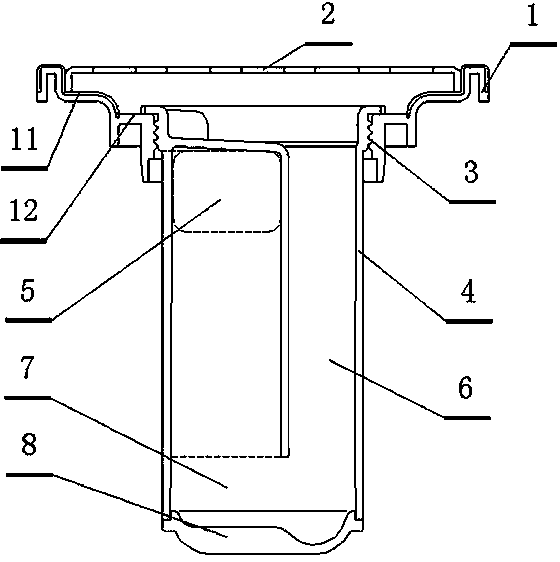

[0016] The total height of connector 1 is 26mm, the upper port is square, the side length of the outer shape is 100mm, and the side length of the inner mouth is 80mm. 2 is a metal material, square, with a side length of 80mm; the thread 3 is M48×2; the body 4 has a total height of 92mm, an outer diameter of 44.6mm, and a wall thickness of 2mm; the drain outlet 5 is 15mm high and 26mm wide, and the drain chamber 6 is a small semicircle The height of the semicircle is 14.6mm, the remaining volume of the body 4 is the drainage function space 10 and the reverse water cavity 9, the drainage function space 10 is a semicircle height of 20.3mm; the height of the channel 7 from the bottom of the body 4 is 20mm; the total height of the bottom cover 8 is 9.5mm, The shape is the same as the shape of the cross-sectional area of the bottom of the body 4, the height of the connecting table is 3mm, fixedly connected with the bottom of the body 4, and the concave height is 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com