pneumatic tire

A technology for pneumatic tires and tires, which is applied to heavy-duty tires, tire parts, tire treads/tread patterns, etc., and can solve the problems of reducing the volume of lateral grooves and poor drainage performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

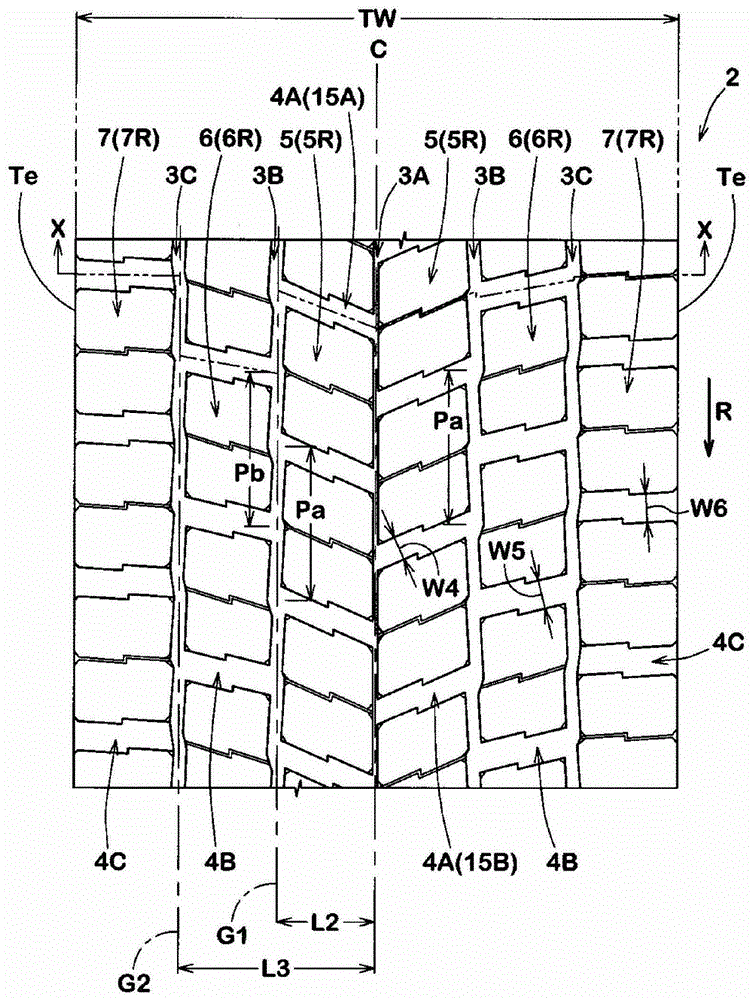

[0066] In order to confirm the effect of the present invention, the figure 1 The test was carried out on a 11.00R20 heavy-duty pneumatic tire with a basic pattern and based on the specifications in Table 1. In addition to the grooves listed in Table 1, the groove width and angle of each groove are as follows: figure 1 shown. In addition, the main common specifications of each tire are as follows.

[0067] Tread contact width TW: 242.4mm

[0068] Groove depth of each main groove: 21.0mm

[0069] Groove depth of central transverse groove: 21.0mm

[0070] The groove depth of the middle horizontal groove: 21.0mm

[0071] The groove depth of the shoulder: 14.5mm

[0072] Groove depth of fine groove: 2.0mm

[0073] The test method is as follows.

[0074]

[0075] Each test tire was mounted on all wheels of a Japanese-made truck (2-D vehicle, ABS brake mounted) with a load capacity of 8 t under the following conditions. Then, the test driver drove the test vehicle on a tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com