Grinder oil seal assembly

A combination and oil seal technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of oil seal heating, wear and tear, etc., to prevent easy leakage and ensure normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

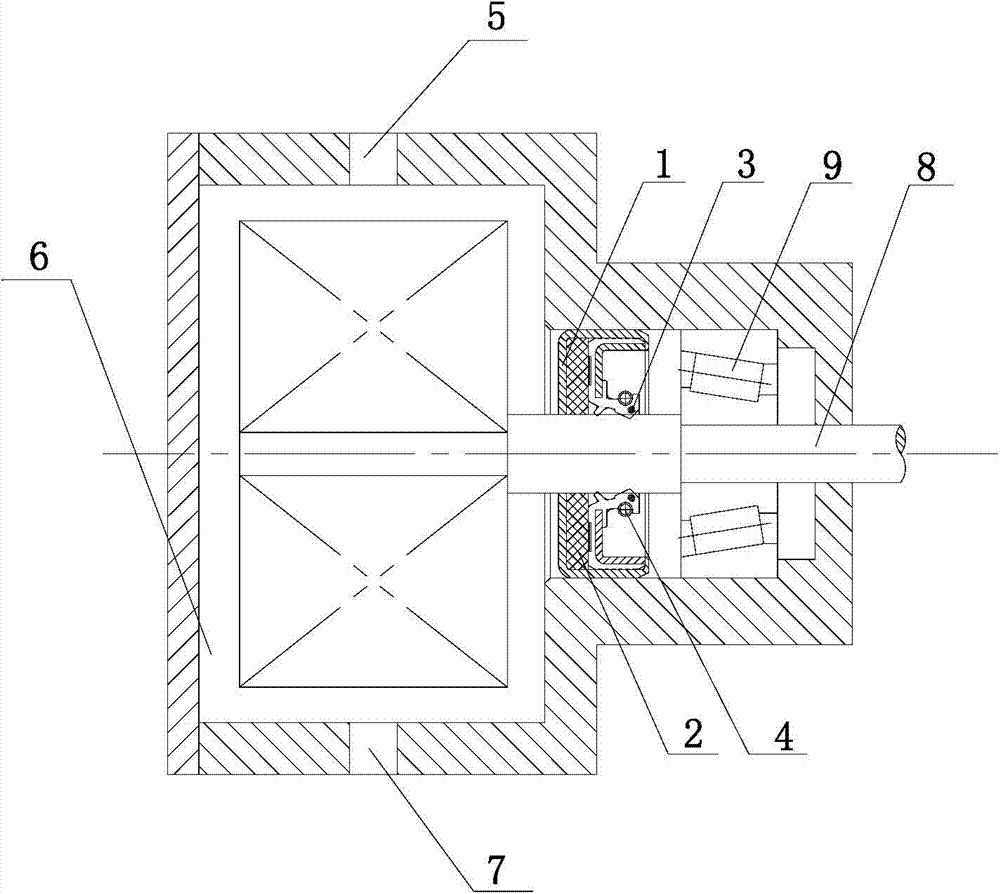

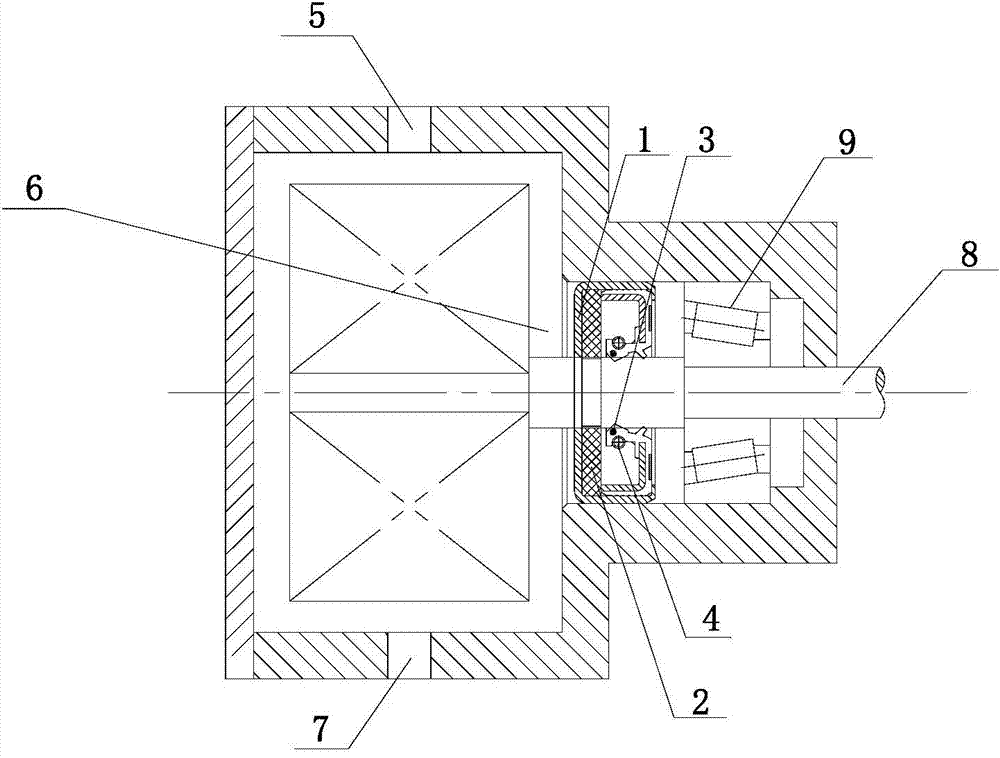

[0014] Such as figure 2 As shown, a shredder oil seal assembly includes a felt 2 and an oil seal 3 , and the oil seal 3 is mounted on the felt 2 in reverse. The oil seal 3 is in the shape of a ring. One end of the oil seal 3 has a spring 4 . The spring end of the oil seal 3 is installed near the felt 2.

[0015] After assembling the spring end of the oil seal 3 of the oil seal assembly 1 at the end 6 of the crushing chamber, the powdery fine particles rotate with the main shaft 8 and break through the lip of the end of the oil seal 3 with spring to effectively block it, preventing or delaying its entry into the bearing 9. The 3 secondary lips of the oil seal will also effectively prevent the high-temperature lithium-based grease from easily leaking, which can ensure the normal use of the bearing 9.

[0016] The foregoing embodiment is only an example of the present invention, and is not intended to limit the implementation and scope of rights of the present invention. All ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com