A high temperature sensor

A temperature sensor and high temperature technology, applied in thermometers, instruments, scientific instruments, etc., can solve the problems of not meeting the requirements of the control system, poor insulation, short service life, etc., to achieve convenient and flexible installation, small time constant and long service life high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions created by the present invention are described in detail in conjunction with the accompanying drawings and embodiments.

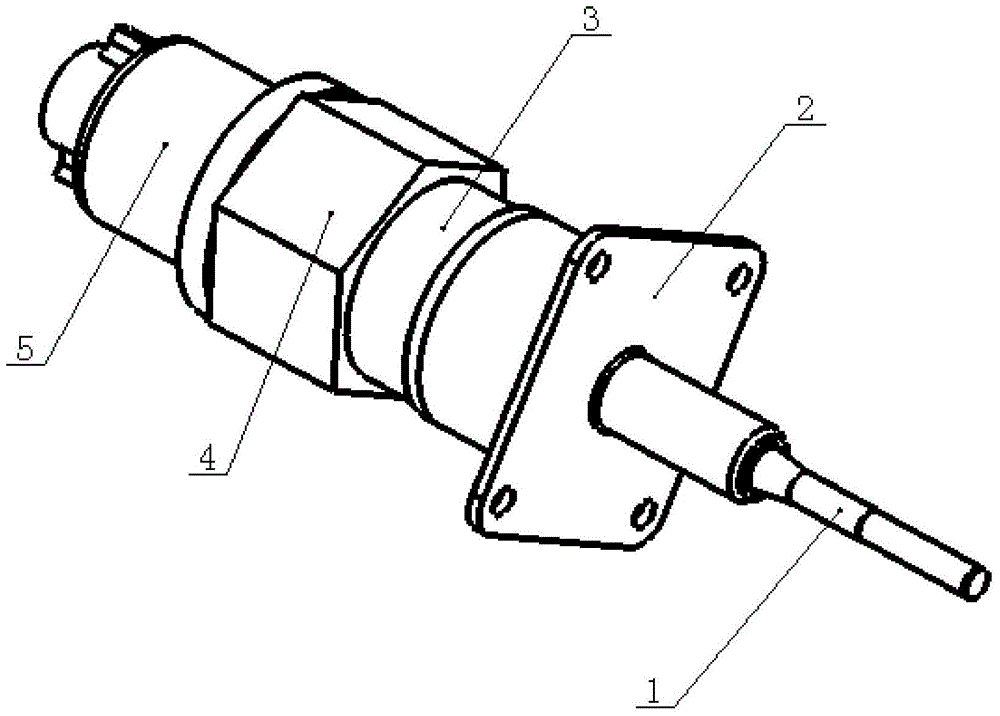

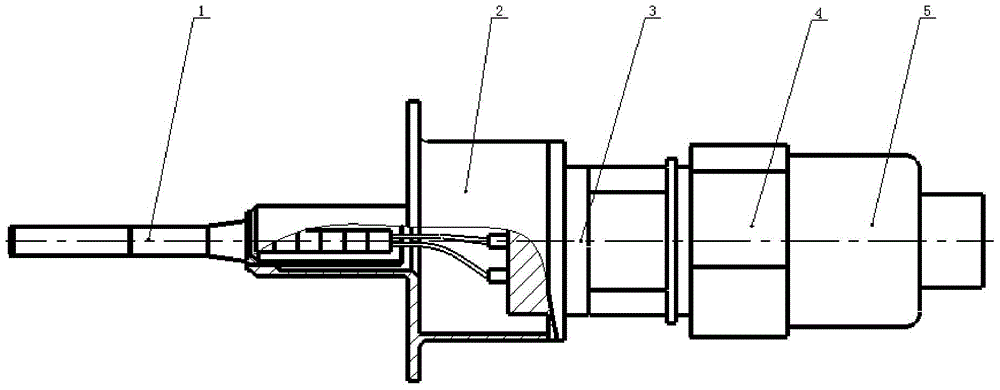

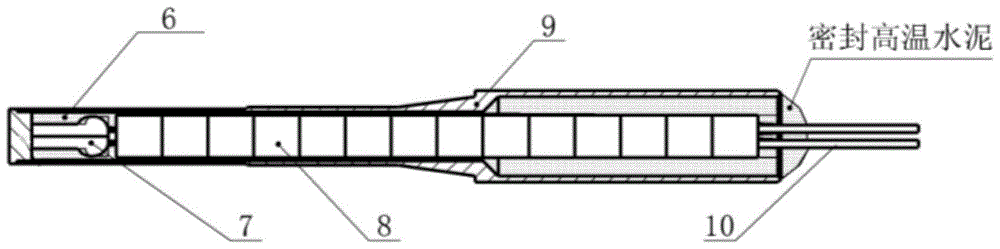

[0028] Such as Figure 1-6 As shown, a high-temperature temperature sensor includes a platinum resistance assembly 1, a mounting sleeve 2, a socket 3, a plug 4 and a tail piece 5 arranged in sequence; the platinum resistance assembly includes a protective cover 9 and a protective cover 9 Platinum resistor 7, insulating bushing 8, the lead wire of platinum resistor 7 is welded with nickel wire 10 and penetrates into insulating bushing 8; the material of insulating bushing 8 is alumina ceramics, which protects, isolates and insulates platinum resistor 7; The gap between the platinum resistor 7 and the protective cover 9 is filled with magnesia slurry 6 with good thermal conductivity, and the tail of the platinum resistor component 1 is sealed with high-temperature cement; the grade of high-temperature cement is 919; the problem ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com