A quick-mounted cold chain verification tester

A tester and cold chain technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems that there is no practical and feasible equipment realization, and it is difficult to achieve theoretical indicators, so as to achieve strong practicability and resistance Intrusive, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

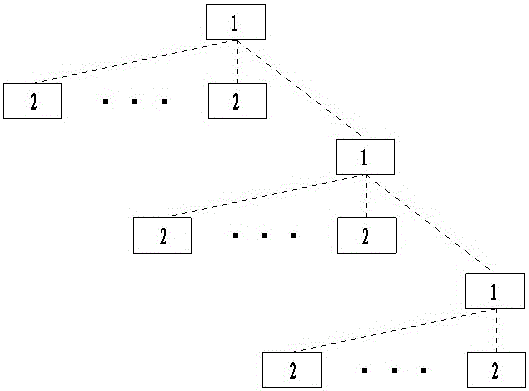

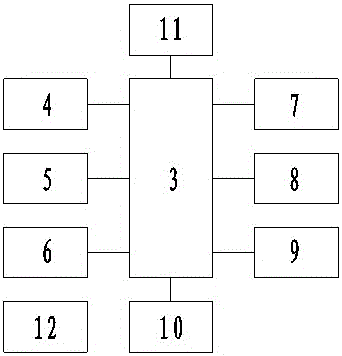

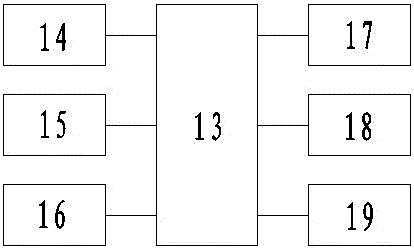

[0022] Such as figure 1 As shown, a quick-mounted cold chain verification tester of the present invention includes: a multi-layer wireless intelligent temperature and humidity monitoring network, figure 1 Shown is a 3-layer network, the wireless intelligent temperature and humidity monitoring network is composed of a wireless intelligent temperature and humidity monitoring management machine 1 and a wireless intelligent temperature and humidity monitoring terminal machine 2, and the wireless intelligent temperature and humidity monitoring management machine 1 communicates with The wireless intelligent temperature and humidity monitoring terminal 2 is connected to communicate, and the wireless intelligent temperature and humidity monitoring network and the superior wireless intelligent temperature and humidity monitoring network rely on their own wireless intelligent temperature and humidity monitoring management machine 1 to communicate through the wireless radio frequency netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com