A closed-loop control method for fuel cell water management

A fuel cell water and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, adaptive control, etc., can solve problems such as limited scope of application, and achieve the effects of short control period, clear control objectives, and favorable engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

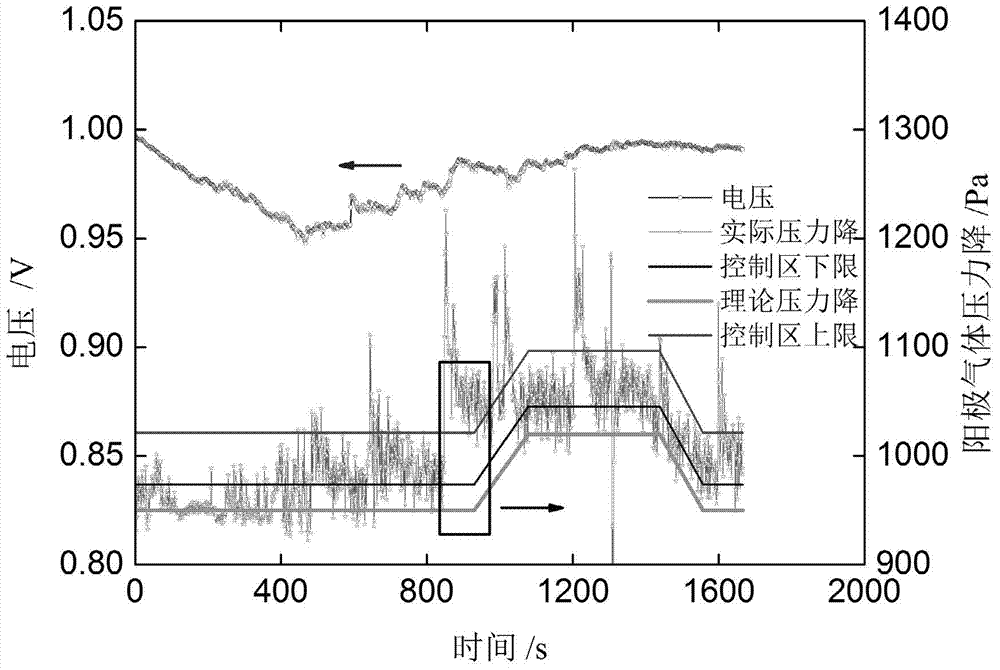

[0017] figure 1 is the experimental curve of the method of the present invention applied on a double-sheet fuel cell. exist figure 1 Among them, the method of the present invention can be explained as follows:

[0018] (1) The parameters of the anode gas pressure drop control interval of the fuel cell in this figure are designed as: α=1.025, β=1.075. The judgment time is designed as: t 1 =180,t 2 =60.

[0019] (2) From about 860s to 920s, the actual value of the anode gas pressure drop is continuously higher than the upper limit of the control interval and exceeds the judgment time t 2 , illustrating the tendency for fuel cell flooding to occur. Start the operation of the fuel cell water management closed-loop control method, increase the fuel cell temperature T, and obtain ΔT=5 through the state solution at this time.

[0020] (3) Incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com