A Modular Reconfigurable Snake Robot

A snake-shaped robot and modular technology, applied in the field of robotics, can solve the problems of insufficient compact structure, poor control accuracy, long control cycle, etc., and achieve the effects of improving convenience, short control cycle, and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

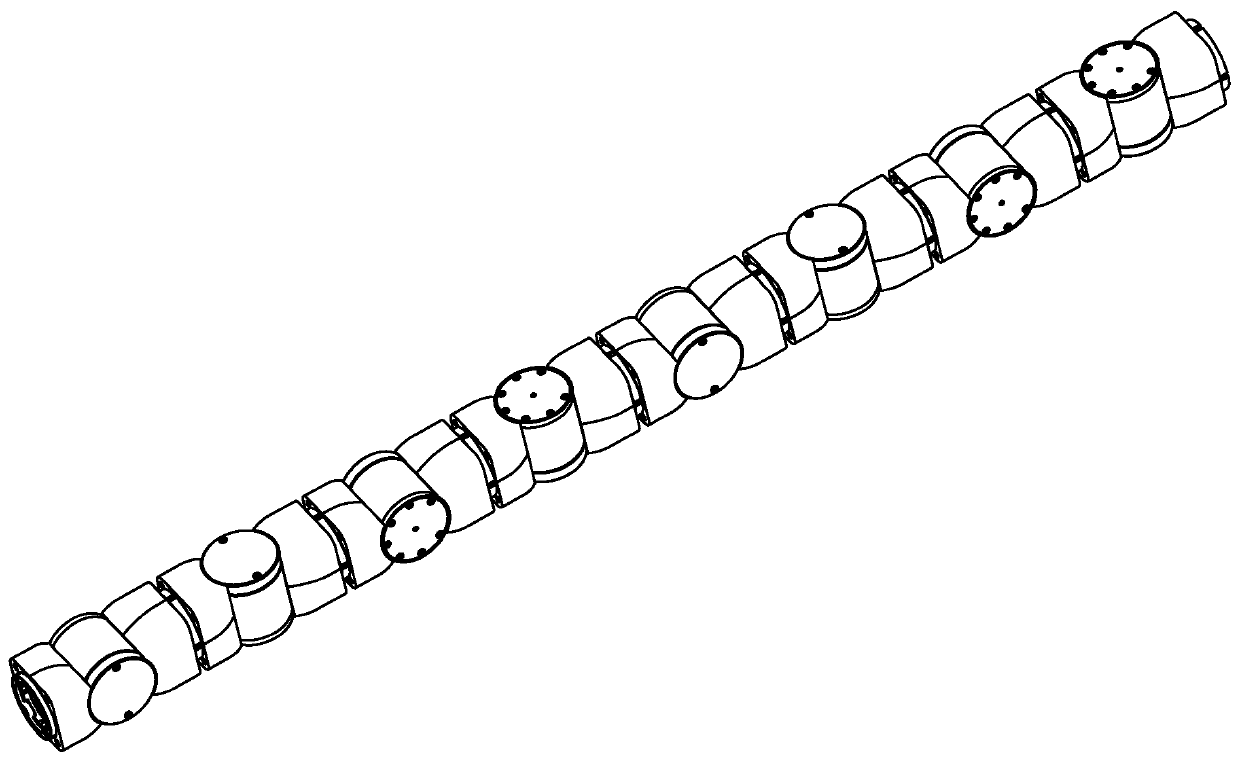

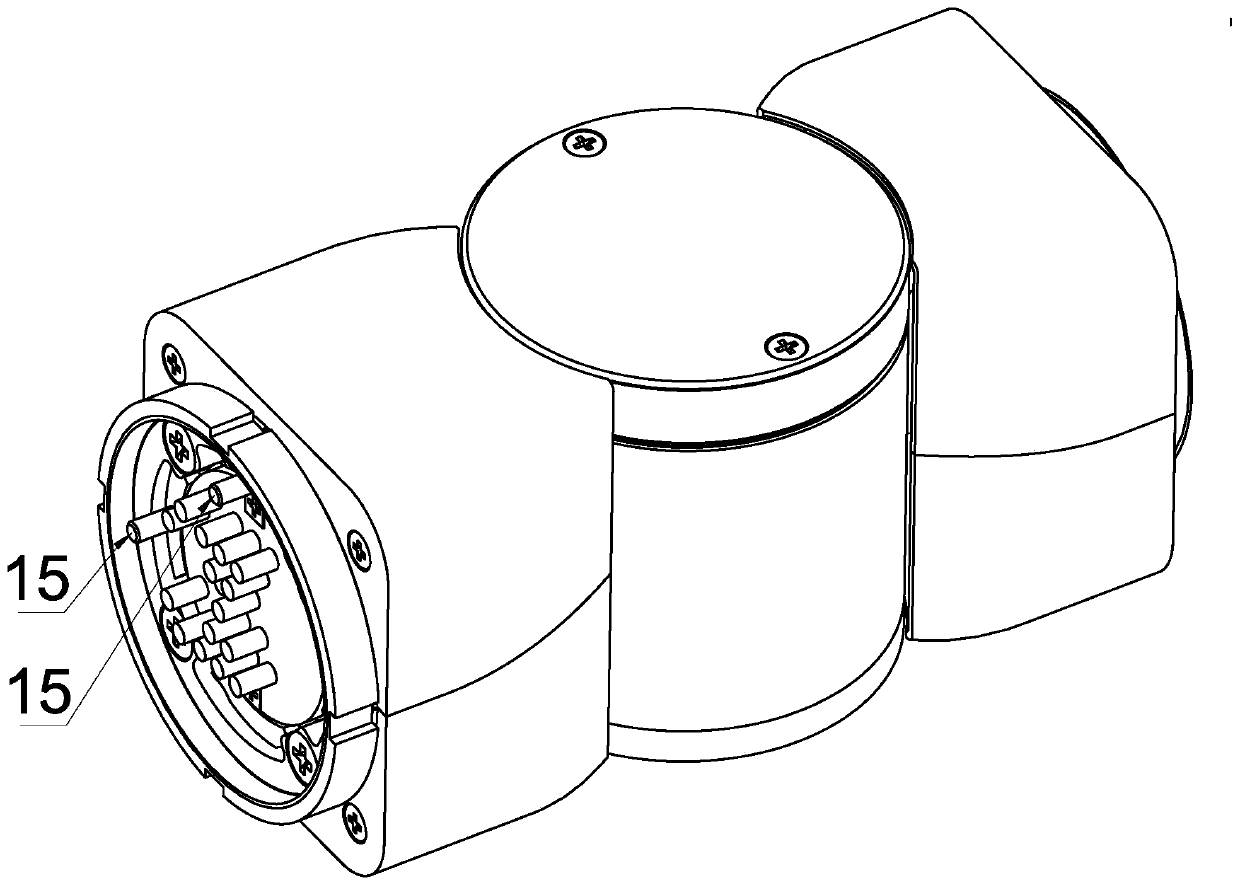

specific Embodiment approach 1

[0030] Specific implementation mode one: as Figure 1-5 As shown, the modular reconfigurable snake-like robot of this embodiment includes a plurality of modular joints connected end to end, two adjacent modular joints are rotated by 90°, and two adjacent modular joints are connected by cylindrical pins. The connection is positioned and arranged orthogonally. The modular joint includes a joint input piece, a joint output piece, an intermediate shaft section, a motor assembly and a harmonic reducer, and the two ends of the intermediate shaft section are respectively provided with a joint input piece and a joint output piece. The motor assembly and the harmonic reducer are arranged side by side inside the intermediate shaft joint, the output end of the motor assembly is connected with the harmonic reducer, the motor assembly drives the harmonic reducer to rotate, and the harmonic reducer drives the joint output Execute the swing motion with the intermediate shaft joint as the axi...

specific Embodiment approach 2

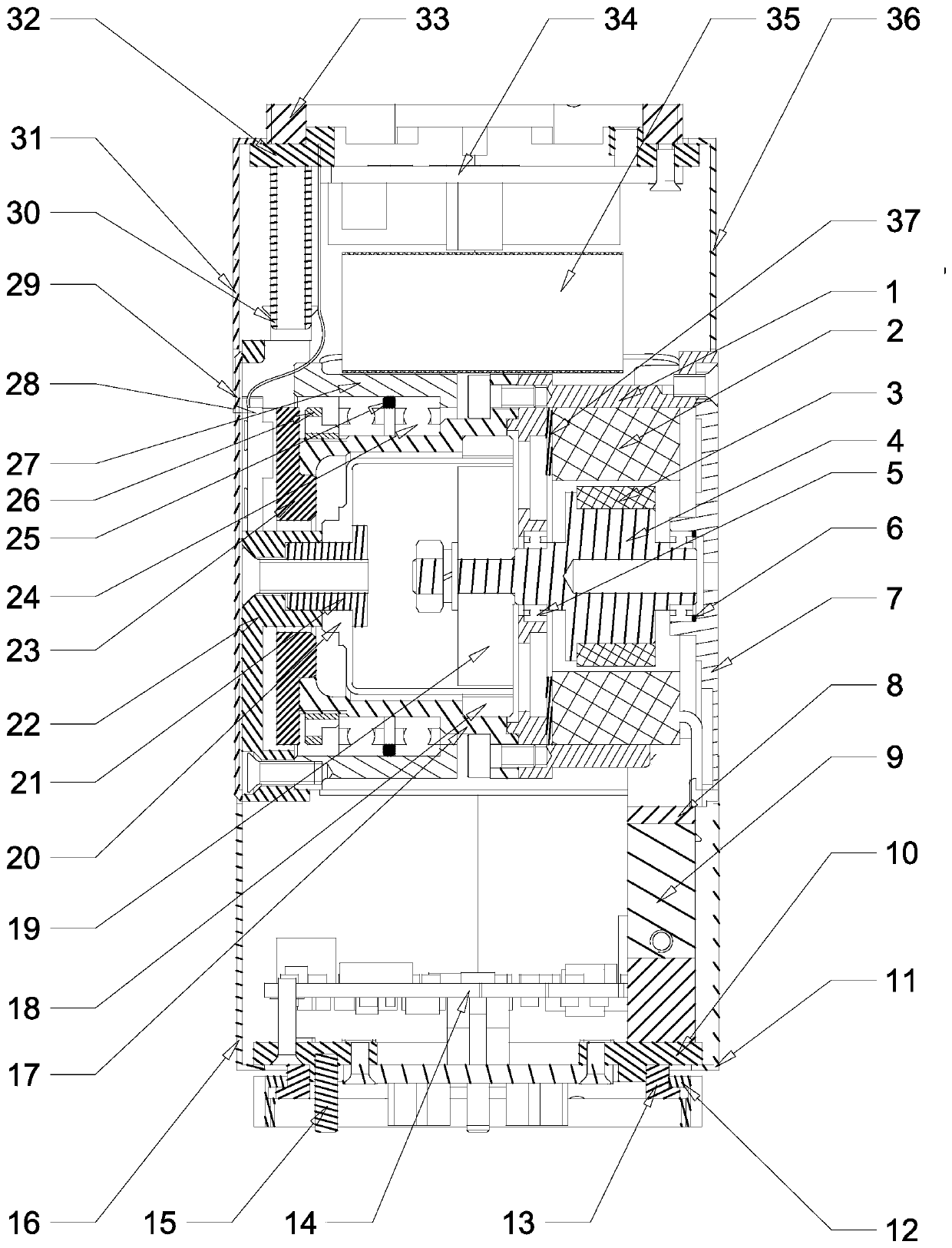

[0033] Specific implementation mode two: as figure 2 , image 3 and Figure 4 As shown, the motor assembly of this embodiment includes a motor housing 1, a motor stator 2, a motor rotor 3, a motor shaft 4 and a motor end cover 7, the motor housing 1 is a cylindrical shell, and the motor housing 1 is arranged inside the intermediate shaft joint. The motor shaft 4 is arranged inside the motor housing 1 and is connected to the motor end cover 7, the motor rotor 3 is set on the motor shaft 4, the motor stator 2 is set outside the motor rotor 3 and is fixedly installed on the inner wall of the motor housing 1, A spacer 37 is arranged between the motor casing 1 and the motor stator 2 .

[0034] In this embodiment, the motor stator 2 is fixedly connected to the motor casing 1 by glue bonding, and the motor rotor 3 is also fixedly connected to the motor shaft 4 by glue bonding. The motor shaft 4 and the first deep groove ball bearing 5 The inner ring is closely matched, and when t...

specific Embodiment approach 3

[0035] Specific implementation mode three: as image 3 As shown, the motor assembly of this embodiment also includes two first deep groove ball bearings 5 and a gasket 6, the motor shaft 4 is installed in the motor housing 1 through the two first deep groove ball bearings 5, and the gasket 6 is arranged on the motor Between the end cover 7 and the first deep groove ball bearing 5 . In this way, one end of the motor shaft 4 is connected to the motor casing 1 through a deep groove ball bearing 5, and the other end of the motor shaft 4 is connected to the motor end cover 7 through another deep groove ball bearing 5, and the motor end cover 7 is arranged on on the inner wall of the intermediate shaft joint. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com