Steam turbine valve control method, device and system supporting control logic reconfiguration

A technology of control logic and valve control, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of delay in response speed, flexible adjustment of basic control logic and additional logic, poor operability, etc., to reduce equipment costs, Fast processing cycle, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

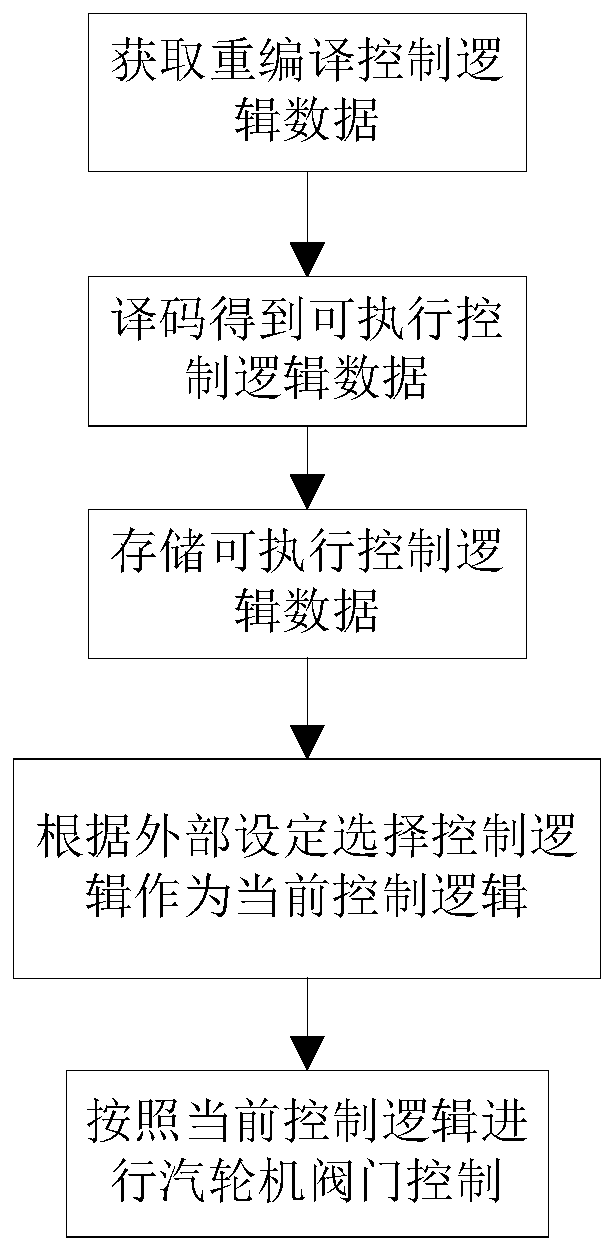

[0049] refer to figure 1 As shown, the present embodiment is a steam turbine valve control method, including:

[0050] Obtain corresponding recompilation control logic data in response to external input having recompilation control logic data;

[0051] Decoding the obtained recompiled control logic data to obtain corresponding executable control logic data;

[0052] Store the executable control logic data obtained by each decoding;

[0053] Select the corresponding executable control logic data according to the external command setting, and update it to the current control logic;

[0054] The steam turbine valve control is performed according to the current control logic.

[0055] In application, the method of this embodiment is executed by the valve control module of the steam turbine to realize the reconfiguration of the online control logic on the module side, thereby improving the response speed of the valve control of the steam turbine.

[0056] The method in this emb...

Embodiment 2

[0060] Based on the same inventive concept as Embodiment 1, this embodiment is a steam turbine valve control device, including:

[0061] The recompilation data acquisition module is used to obtain the corresponding recompilation control logic data in response to external input of recompilation control logic data;

[0062] A control logic decoding module, configured to decode the obtained recompiled control logic data to obtain corresponding executable control logic data;

[0063] The data storage module is used to store the executable control logic data obtained by each decoding;

[0064] The control logic update module is used to select the corresponding executable control logic data according to the external instruction setting, and update it to the current control logic;

[0065] The control logic execution module is used for controlling the steam turbine valve according to the current control logic.

Embodiment 3

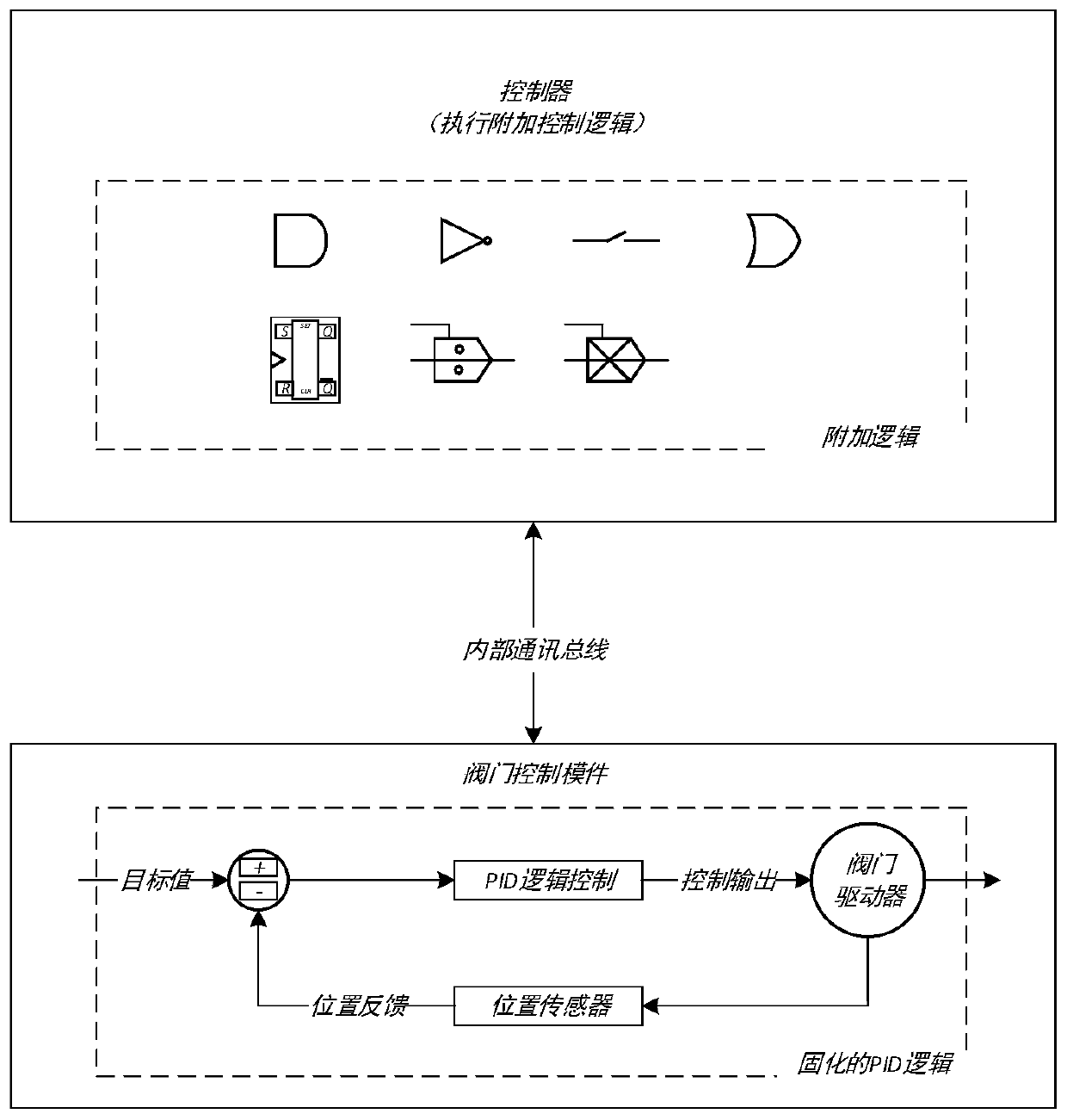

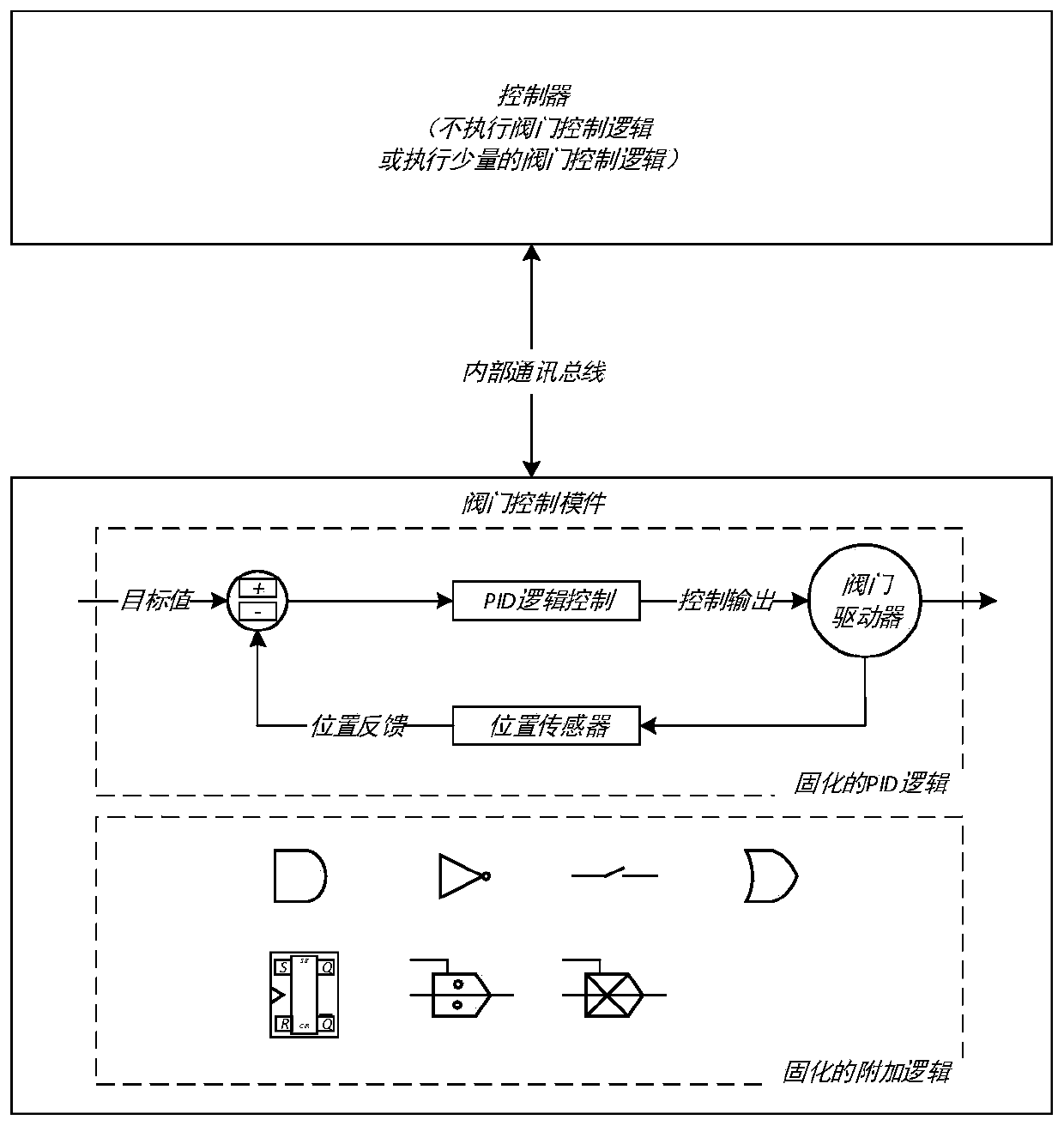

[0067] This embodiment is a steam turbine valve control module, refer to Figure 4 As shown, the module includes a control logic update interface, a host control interface, a data storage module and a data processing module, and the data processing module includes a control logic decoding unit, a control logic updating unit and a control logic execution unit;

[0068] The data processing module obtains the externally input recompiled control logic data through the control logic update interface, and then decodes the recompiled control logic data through the control logic decoding unit to obtain the corresponding executable control logic data and store it in the data storage module;

[0069] The data processing module obtains the external control logic setting instruction through the upper control interface, and then selects the corresponding executable control logic data according to the external instruction setting through the control logic updating unit, and updates it to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com