A stick-shaped safety socket for charging high-power autonomous robots

A technology of autonomous robots and safety sockets, applied in the direction of contact parts, etc., can solve the problems of the safety of charging sockets and the inapplicability of high-power autonomous robots, and achieve the effect of large electrode contact surface, easy operation and good contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

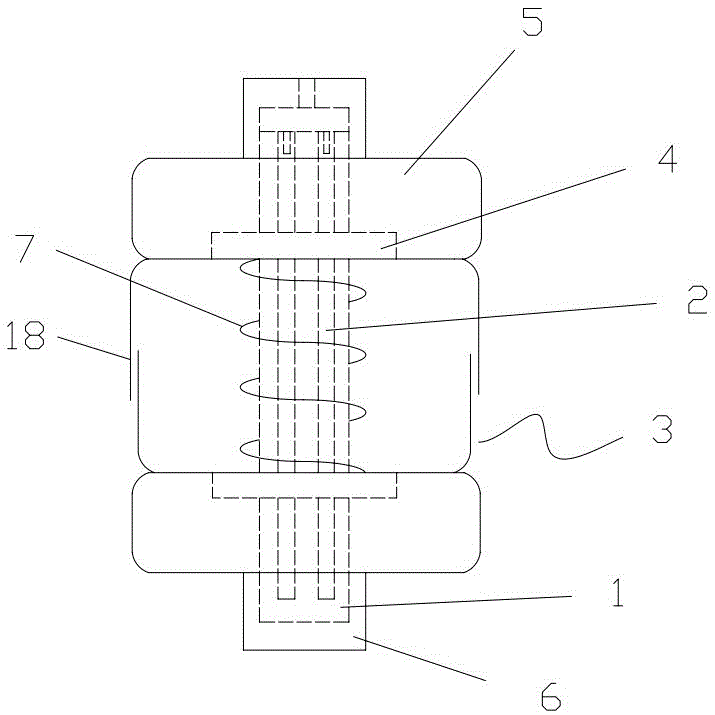

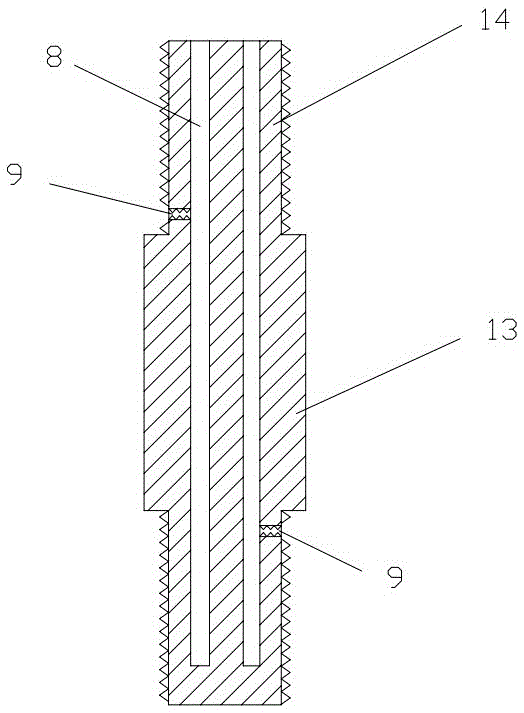

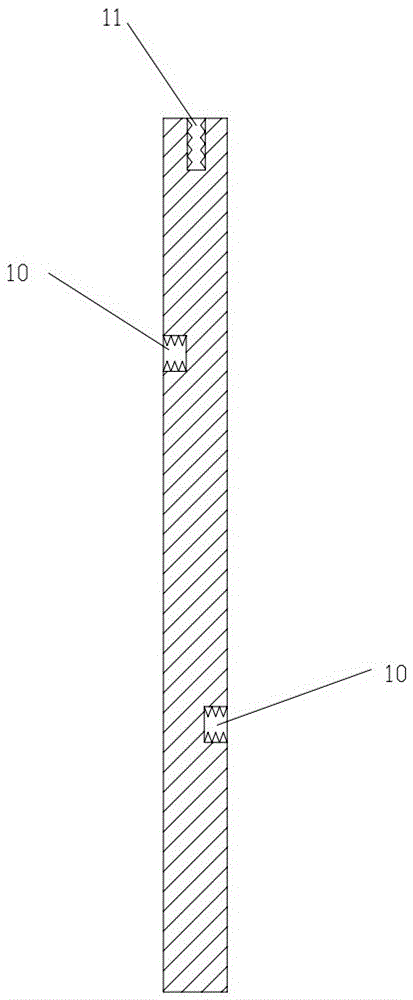

[0020] The rod-shaped safety socket for charging high-power autonomous robots described in the first embodiment, such as figure 1 As shown, the insulating support rod 1, the square copper terminal located in the insulating support rod 2, the movable spring insulating sleeve 3 which is tightly sleeved in the middle section of the insulating support rod, and the symmetrical spring insulating sleeve is located outside the spring insulating sleeve. Ring-shaped copper electrode 4, symmetrical electrode insulating cover 5 which is tightened on the upper and lower sections of the insulating support rod and the ring-shaped copper electrode and located outside the spring insulating sleeve, symmetrical insulating end cover 6 respectively tightened on both ends of the insulating support rod, and sleeved on the insulating support The spring 7 is placed on the rod and placed in the spring insulating sleeve; the insulating end cover, the electrode insulating cover and the spring insulating sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com