Scum juice separating device

A technology of separation of slag juice and clutch parts, which is applied in the field of slag juice separation device, can solve the complicated problems of soybean milk maker, and achieve the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the above and other objectives, features and advantages of the present invention more obvious and easy to understand, the following is a detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings:

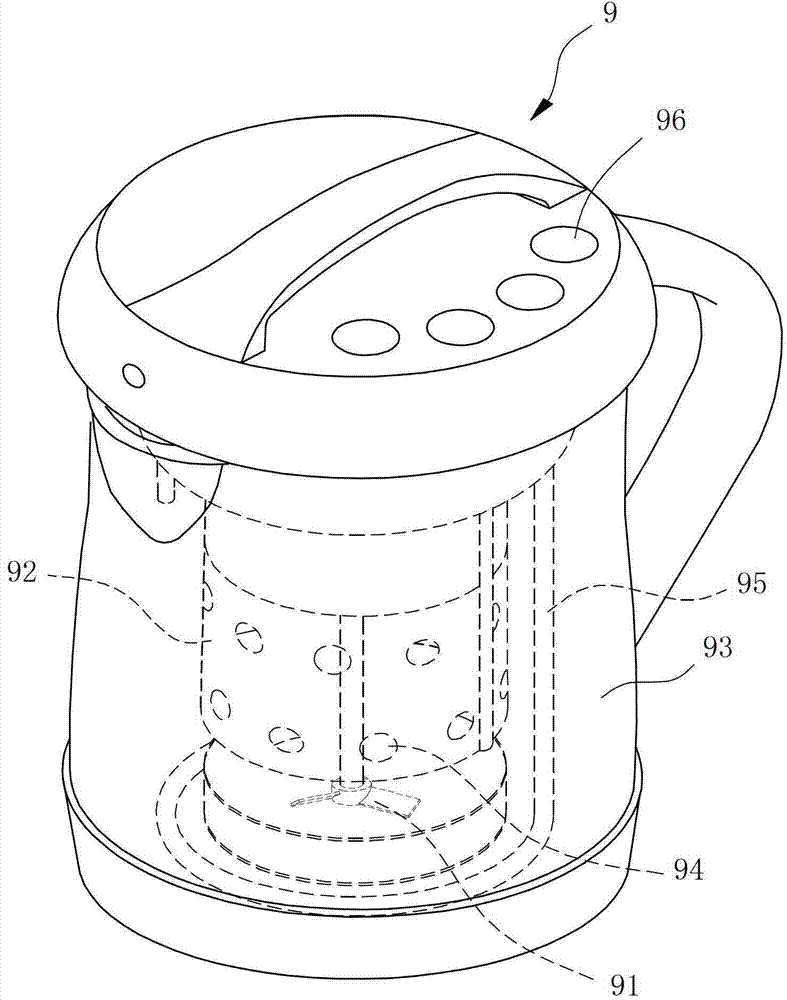

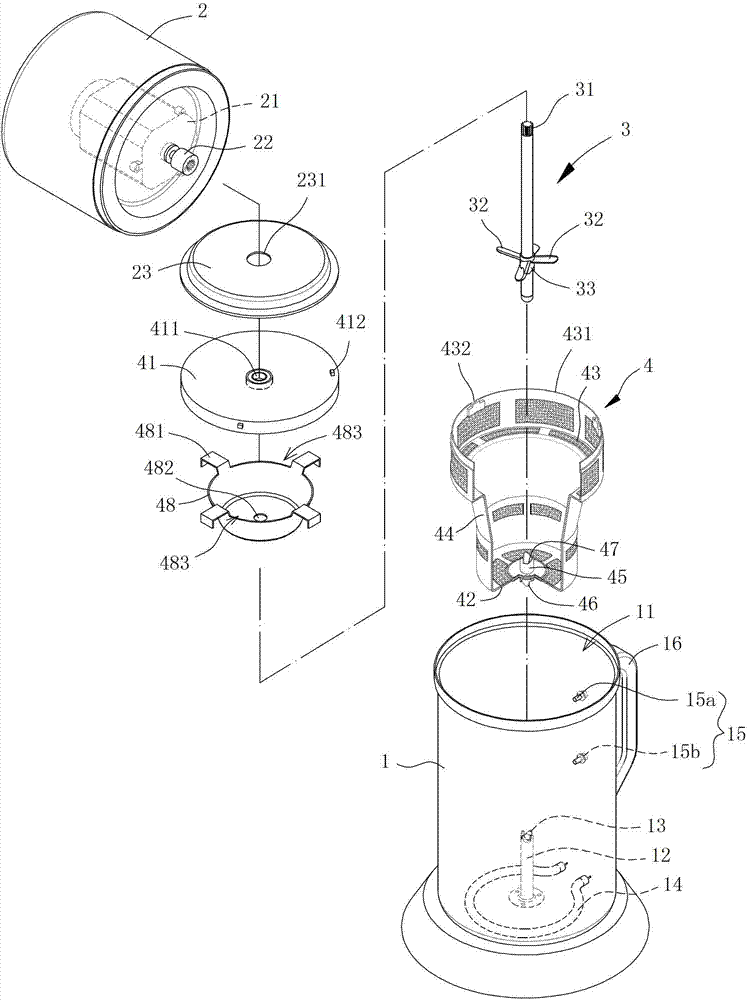

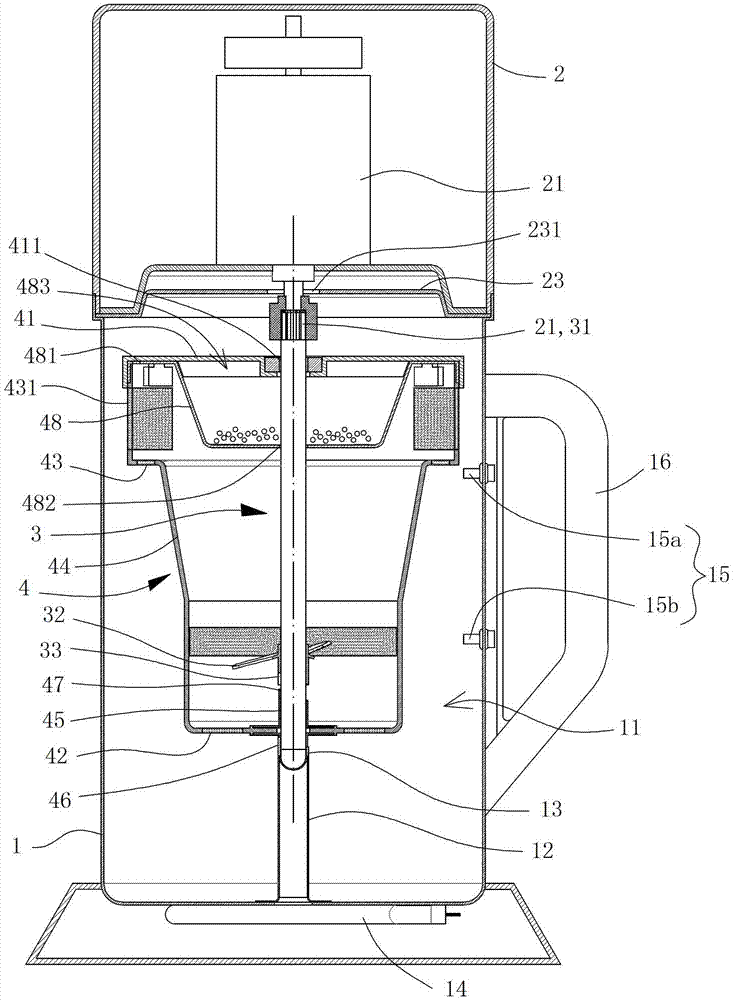

[0071] Please refer to figure 2 , 3 As shown, it is a preferred embodiment of the present invention. The slag juice separation device of this embodiment includes a container 1, an upper seat 2, a rotating shaft 3, and a filtrate member 4. The upper base 2 can be combined with the opening of the container 1, the rotating shaft 3 can penetrate through the filtrate member 4, the rotating shaft 3 and the filtrate member 4 can be placed in the container 1; the rotating shaft 3 can be A power element 21 drives the rotation in the first direction or the second direction to crush or homogenize the food contained in the filtrate 4; and the filtrate 4 can be driven in the opposite direction via the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com