Slag juice separation device

A technology for separation of slag juice and clutch parts, which is applied in the field of slag juice separation devices, can solve the problems such as the complexity of the soybean milk maker, and achieve the effect of convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the above and other purposes, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and detailed descriptions are as follows:

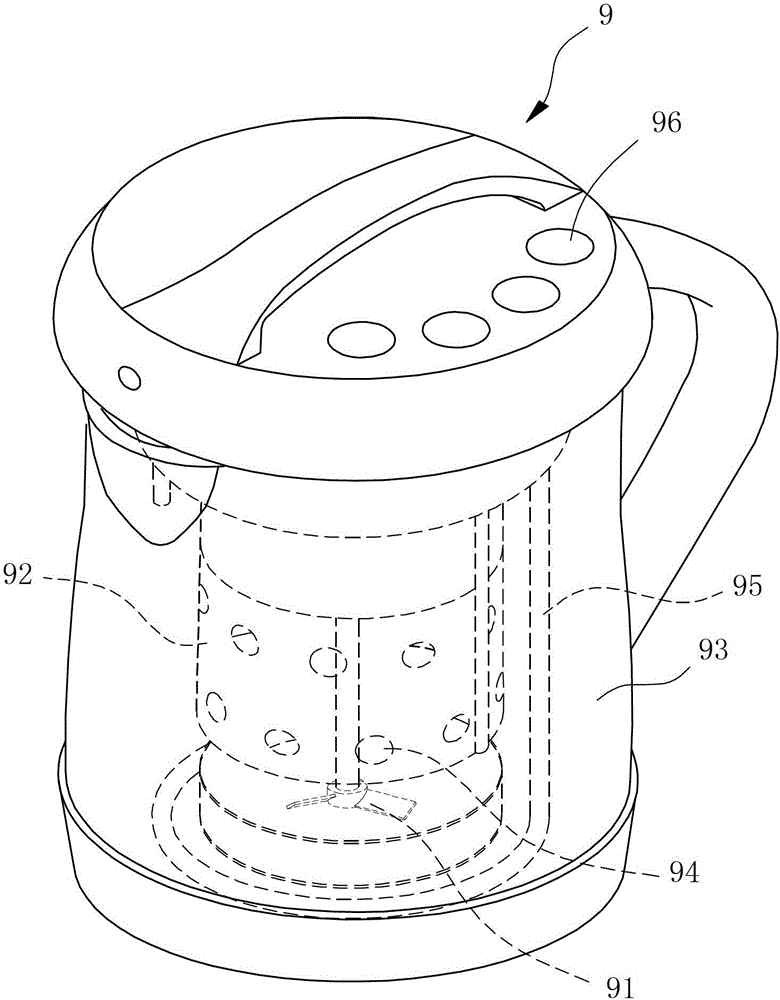

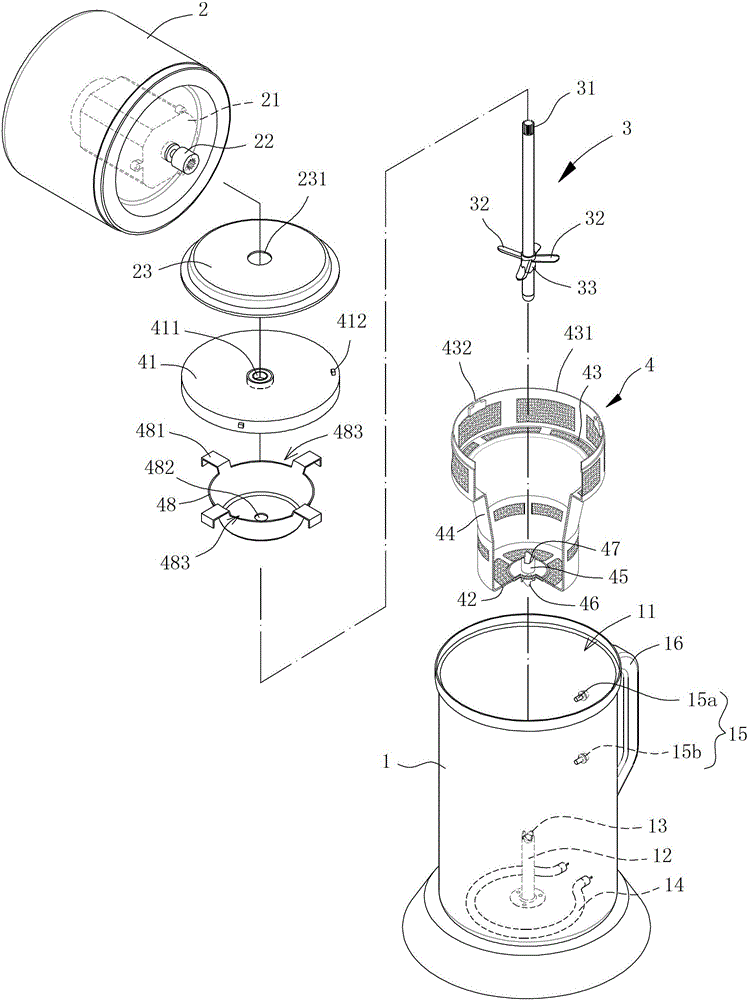

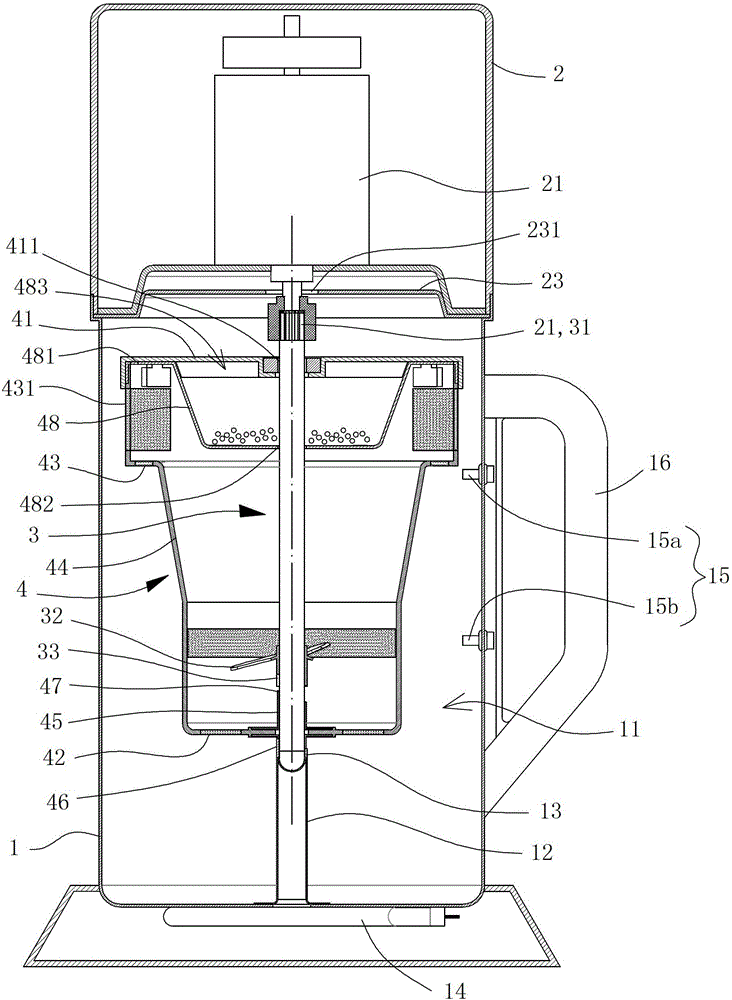

[0071] Please refer to figure 2 , 3 As shown, it is a preferred embodiment of the present invention, and the slag juice separation device of this embodiment is composed of a container 1, an upper seat 2, a rotating shaft 3 and a filtrate member 4. The upper seat 2 can be combined with the opening of the container 1, the rotating shaft 3 can pass through the filtrate part 4, and the rotating shaft 3 and the filtrate part 4 can be placed in the container 1; A power element 21 is driven to rotate in the first direction or the second direction for crushing or homogenizing the food material contained in the filtrate member 4; and the filtrate member 4 can be driven in the opposite direction via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com