Buffer device for food freezing-crusher

A technology of frozen pulverizer and buffer device, which is applied in the direction of grain processing, etc., can solve the problems of easy wear and high noise of the sealing rubber ring, and achieve the effect of protecting the sealing rubber ring, reducing noise and strengthening the shockproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

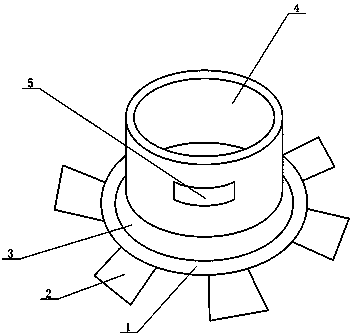

[0012] Such as figure 1 As shown, the present invention provides a buffer device for a frozen food grinder, comprising an annular support washer 1, a buffer boss 3 is fixedly connected to the support washer 1, and a buffer ring 4 is connected above the buffer boss 3. The outer wall of the buffer ring 4 is provided with a shock-absorbing convex strip 5, and an array of supporting protrusions composed of supporting protrusions 2 is arranged at intervals on the outer circumference of the supporting washer 1, and the space between every two supporting protrusions 2 of the supporting protrusion array is The spacing is 3cm, and the support projection 2 can also be set to be bendable, which can further play a sealing role. In specific implementation, it is considered to eliminate or reduce the impact and vibration brought to the sealing rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com