Material filter

A filter and material technology, applied in the direction of filter screen, chemical instrument and method, solid separation, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

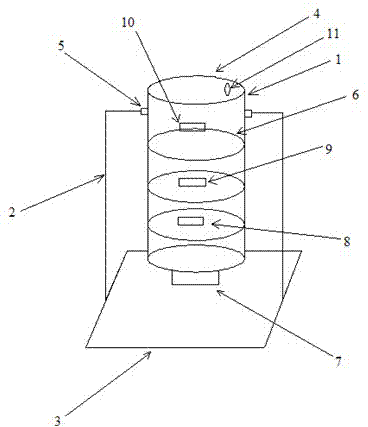

[0015] The material filter of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 Shown is a schematic diagram of a material filter according to the present invention, which includes a filter barrel 1, a support 2 and a base 3, the filter barrel 1 is connected to the support 2 through a rotatable shaft 5, the support 2 is fixedly connected to the base 3, and the filter The bottom of the bucket 1 is higher than the base 3, the top of the filter bucket 1 has a bucket cover 4, and the inside of the filter bucket 1 is provided with an upper, middle and lower three-layer filter screen 6, which divides the filter bucket 1 into four spaces, and each space has a corresponding discharge Ports 7, 8, 9 and 10, the pore diameter of the filter screen 6 gradually decreases from top to bottom, which can separate materials of different sizes from each other. In this embodiment, the filter barrel 1 is made of transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com