Lifting hook and crane provided with same

A hook and rope technology, applied to the hook and the field with the hook, can solve the problems of low work efficiency, heavy rope, time-consuming and labor-intensive, etc., and achieve the effect of improving work efficiency, simple structure and novel concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

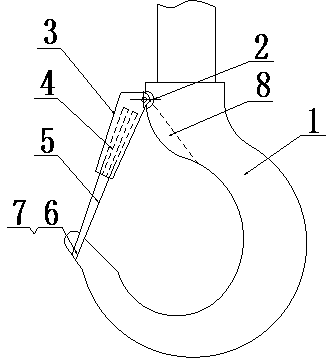

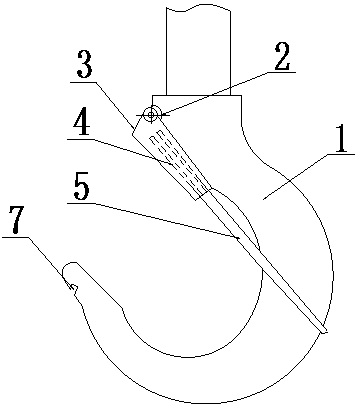

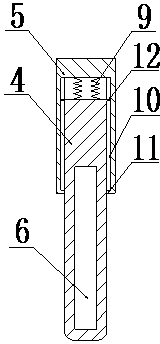

[0016] Depend on figure 1 , 2 It can be seen that a hook includes a hook body 1, an inner space and an opening for accommodating a lifting rope; a baffle mounting seat 2, which is located at one end of the upper opening of the hook body; There is a groove 8 at the side position; the hook also includes a baffle 3, the baffle is composed of a pivot end 4 and a free end 5, the pivot end is pivotally connected with the baffle mounting seat, and the pivot end is Hollow, with a parallel channel 10 inside, a stop protrusion 11 at the mouth of the channel, two springs 9 near the end of the baffle mounting seat at the pivot end; one end of the free end is set in the pivot end, connected with the spring, and the two A stop block 12 is arranged on the side, and the stop block is matched with the parallel channel, and the other end is provided with a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com