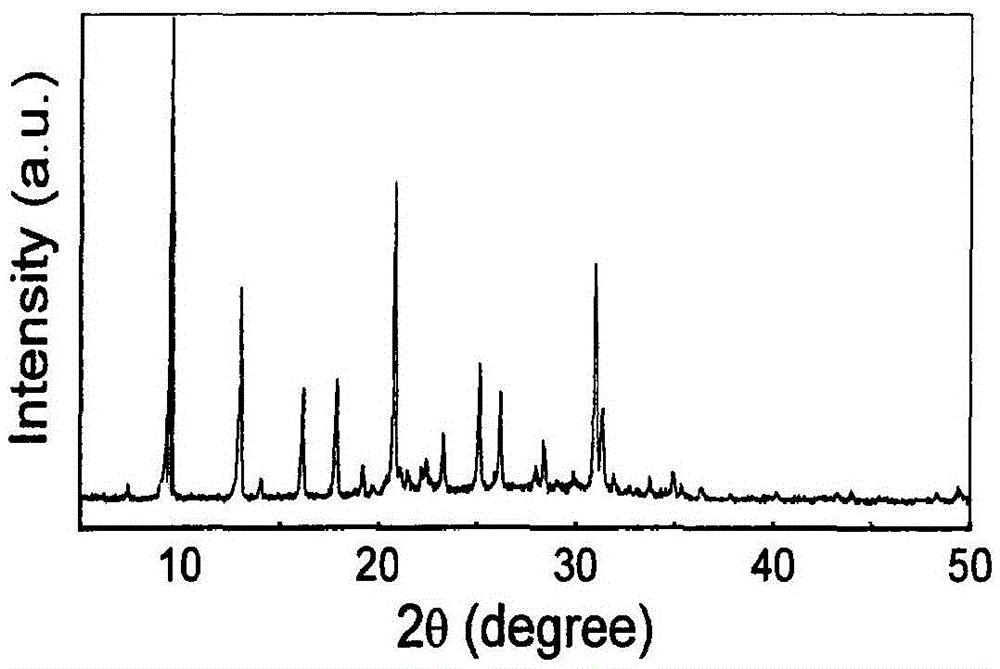

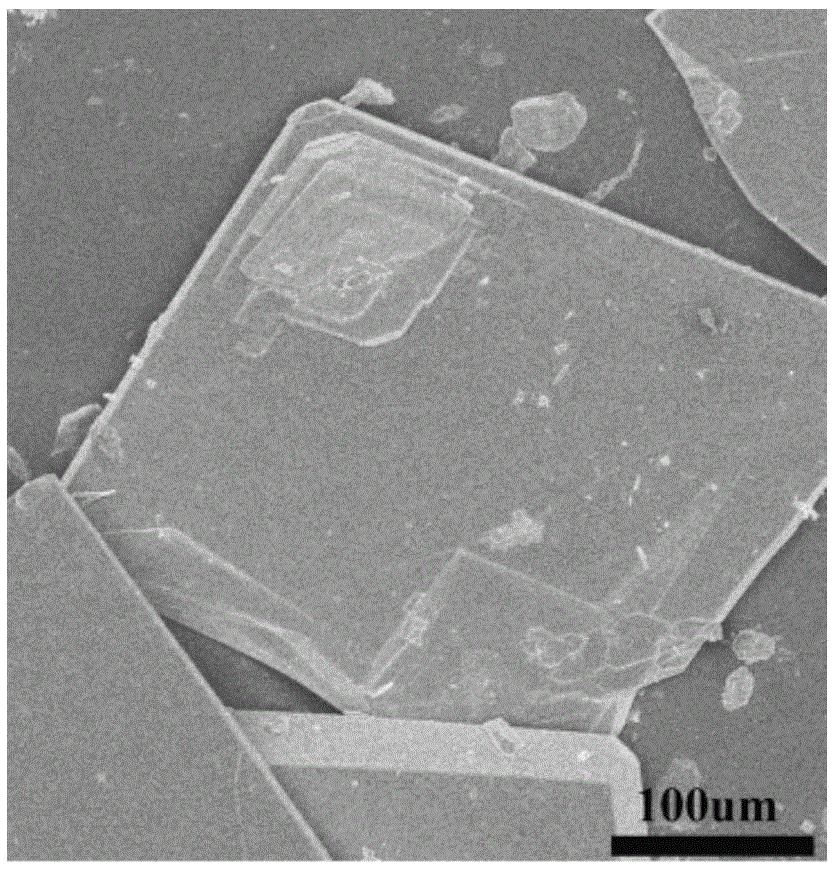

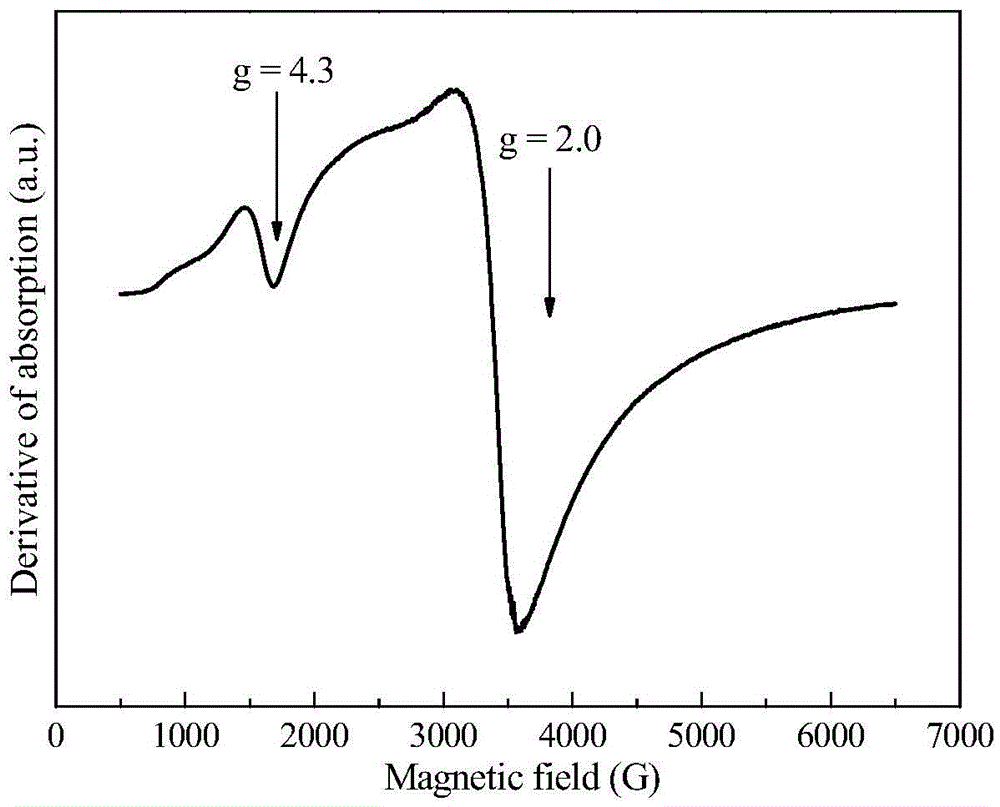

A kind of Fe-sapo-34 molecular sieve with high skeleton iron content and preparation method thereof

A SAPO-34, fe-sapo-34 technology, applied in the field of molecular sieve preparation, can solve the problems of low heteroatom metal content and low catalytic activity, achieve high metal content, high specific surface area, increase B acid and L acid center effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 10g of phosphoric acid and 10g of ethyl orthosilicate to 60ml of deionized water, stir for 15min, then add 11g of K 4 Fe(CN) 6 After continuing to stir for 60 minutes, 8 ml of diethylamine was added, and after 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and crystallized under autogenous pressure of 160° C. for 72 hours. Then the sample was suction-filtered, washed with deionized water until neutral, and dried at 100°C for 6 hours. at 1°C min -1 The rate was programmed to increase the temperature to 550°C, keep the temperature for 5h, and remove the template agent.

Embodiment 2

[0030] Add 10g of phosphoric acid and 12.1g of ethyl orthosilicate to 60ml of deionized water, stir for 15min, then add 11g of K 4 Fe(CN) 6 After continuing to stir for 60 min, 10 ml of diethylamine was added, and after 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and crystallized at an autogenous pressure of 160° C. for 72 hours. Then the sample was suction-filtered, washed with deionized water until neutral, and dried at 100°C for 6 hours. at 1°C·min -1 The rate was programmed to increase the temperature to 550°C, keep the temperature for 5h, and remove the template agent.

Embodiment 3

[0032] Add 8g of phosphoric acid and 12.1g of ethyl orthosilicate to 60ml of deionized water, stir for 15min, then add 11g of K 4 Fe(CN) 6 After continuing to stir for 60 min, 10 ml of diethylamine was added, and after 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and crystallized under autogenous pressure of 180° C. for 72 hours. Then the sample was suction-filtered, washed with deionized water until neutral, and dried at 100°C for 6 hours. at 1°C·min -1 The temperature was programmed to 550°C, and the temperature was kept for 5 hours to remove the templating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com