Construction Technology of Bridge Deep-buried Cap Platform Curtain Structure

A construction technology and curtain technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of insufficient rigidity of single-layer steel sheet piles, unsatisfactory water-stop effect, long construction period, etc., achieve obvious water-stop effect, improve construction efficiency, The effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

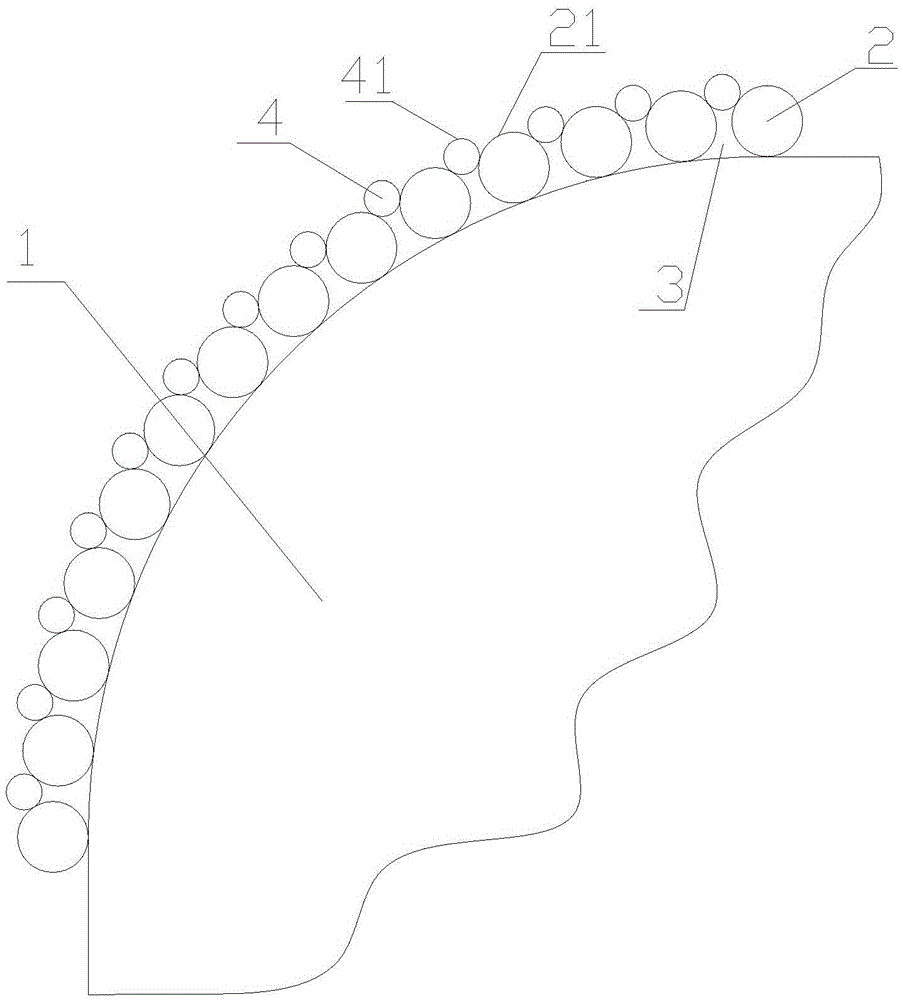

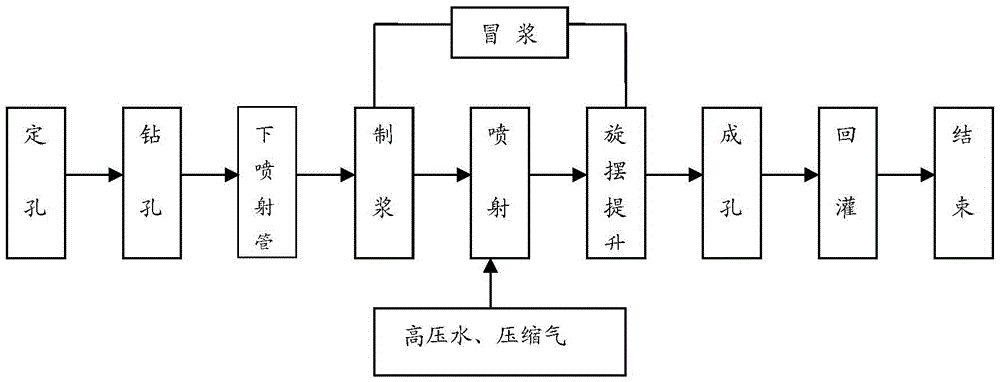

[0019] Referring to the accompanying drawings, it can be seen that the bridge's deep-buried platform cap curtain structure includes a cap contour 1 to be excavated, and is characterized in that a circle of bored piles 2 is arranged on the outer side of the cap contour 1, and the adjacent boreholes Between the cast-in-place piles 2 there is a gap 3 and a jet-spray pile 4 sealing the gap. The jet-spout pile 4 is located outside the bored cast-in-place pile 2, and the tops of the bored cast-in-place pile 2 and the jet-spray pile 4 are both Connected with crown beam.

[0020] The outer peripheral surface 41 of the jet grouting pile 4 is bonded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com