An evaporator flow path

A technology of an evaporator and a first flow path, applied in the direction of evaporator/condenser, refrigeration components, refrigerators, etc., can solve the problems of increased process requirements for air conditioning, inconsistent heat exchange length, low cooling effect, etc., and achieves excellent craftsmanship. , Wide range of safety, the effect of not easy to drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

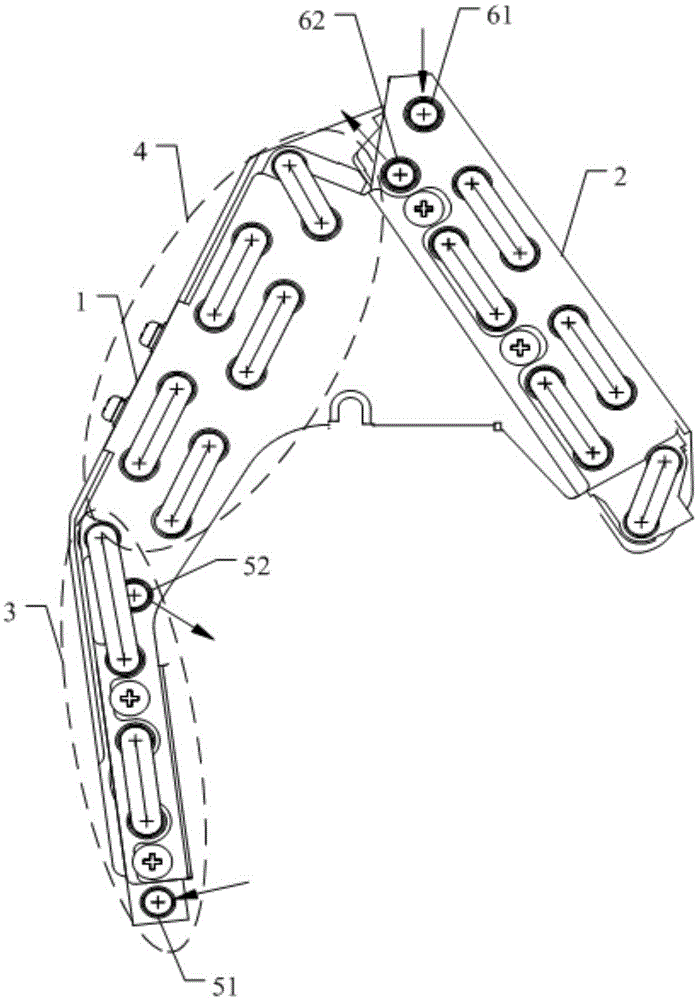

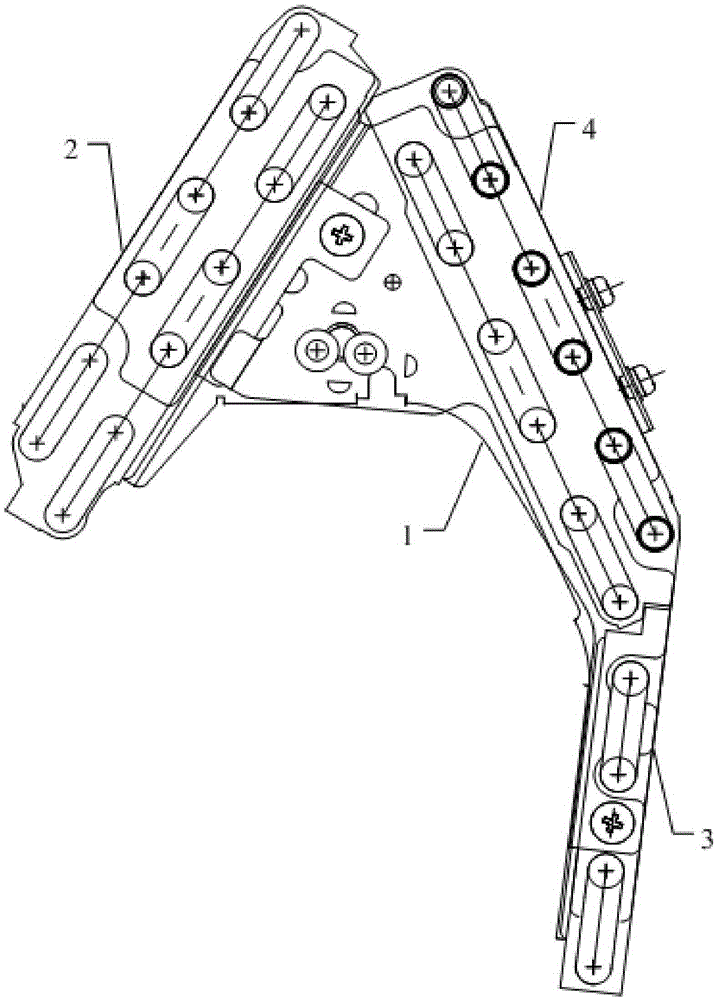

[0031] An evaporator flow path provided in this embodiment includes an evaporator, a first flow path, and a second flow path. The evaporator includes a left branch and a right branch 2, and the left branch is set as a single row of pipes. The lower left branch 3 is composed of the upper left branch 4 configured as a double row of pipes, the lower left branch 3, the upper left branch 4 and the right branch 2 configured as a double row of pipes are connected in sequence,

[0032] The first flow path includes the first liquid inlet pipe 51, the row pipe of the lower left branch 3, the cross pipe 7, the row pipe of the upper left branch 4 and the first liquid outlet pipe 52 connected in sequence, and the cross pipe 7 Connected to the row pipe at the upper end of the left lower branch 3 and the row pipe at the upper end of the left upper branch 4;

[0033] The second flow path includes a second liquid inlet pipe 61 , a drain pipe of the right branch 2 , a drain pipe of the upper le...

Embodiment 2

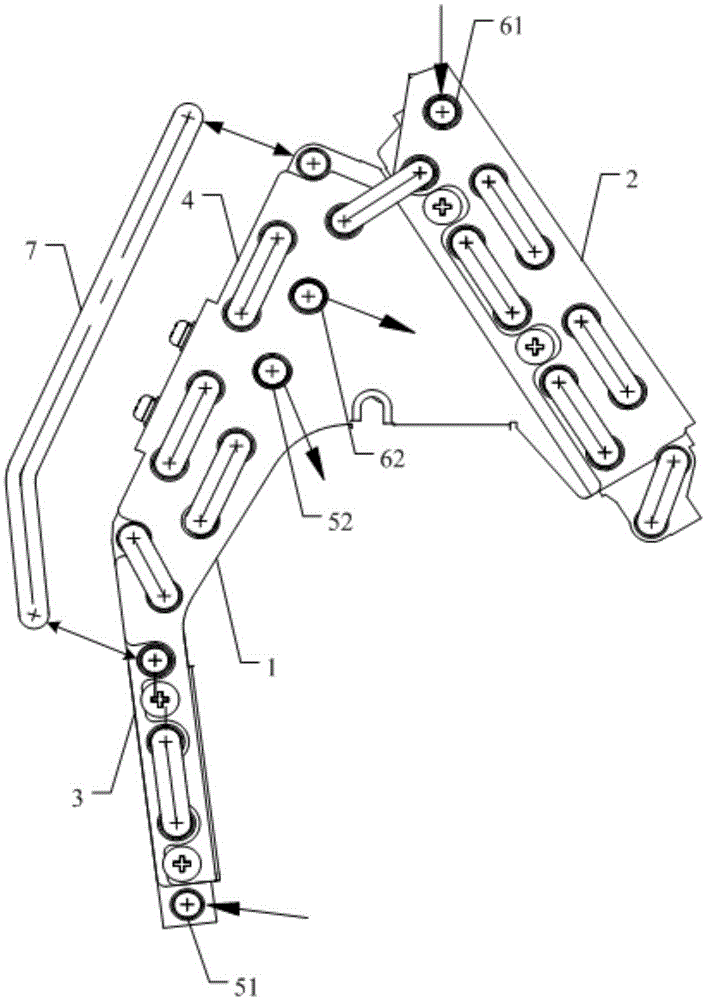

[0040] An evaporator flow path provided in this embodiment includes an evaporator, a first flow path, and a second flow path. The evaporator includes a left branch 1 and a right branch 2, and the left branch 1 is configured as a single The lower left branch 3 of the row of pipes is composed of the upper left branch 4 configured as a double row of pipes, the lower left branch 3, the upper left branch 4 and the right branch 2 configured as a double row of pipes are connected in sequence,

[0041] The first flow path includes the first liquid inlet pipe 51, the row pipe of the lower left branch 3, the cross pipe 7, the row pipe of the upper left branch 4 and the first liquid outlet pipe 52 connected in sequence, and the cross pipe 7 Connected to the row pipe at the upper end of the left lower branch 3 and the row pipe at the upper end of the left upper branch 4;

[0042] The second flow path includes a second liquid inlet pipe 61 , a drain pipe of the right branch 2 , a drain pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap