Heat exchanger, in particular for an over critical cooling circuit

A technology of heat exchanger and refrigeration cycle, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of increasing pressure drop, affecting the effective power of cooling liquid cooler, and air heating, etc. To achieve the effect of reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

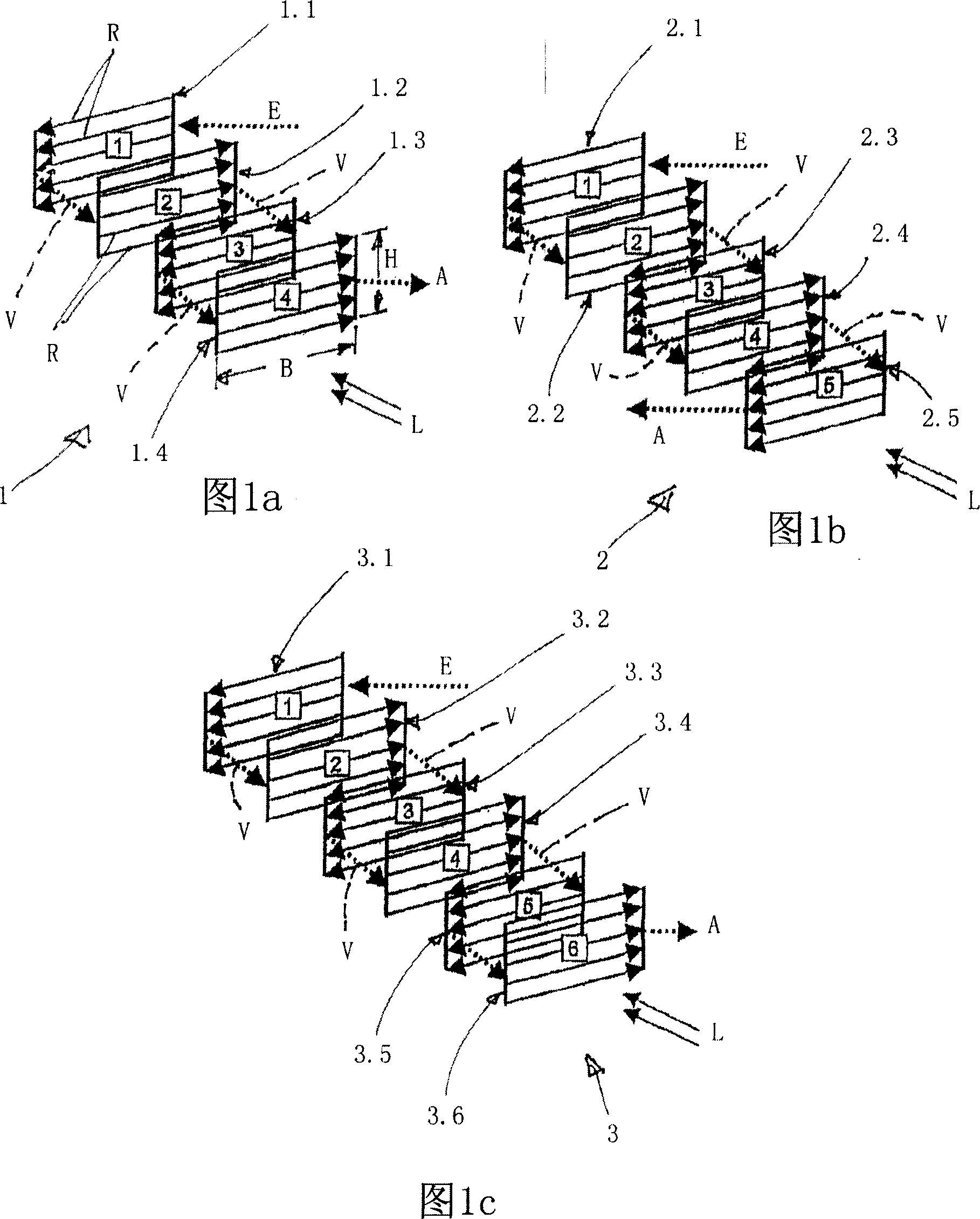

[0032] Figures 1a, 1b and 1c are schematic diagrams of a first embodiment of a heat exchanger according to the invention designed as a gas cooler for a supercritical refrigeration cycle. Such a gas cooler can be used in particular in vehicle air conditioning systems with CO2 (R744) as refrigerant.

[0033] In FIG. 1 a is a four-row pipe system for a gas cooler 1 through which the refrigerant CO2 flows and is cooled by the surrounding air, the flow direction being indicated by the arrow L. In FIG. The gas cooler 1 has four tube rows 1.1, 1.2, 1.3, 1.4 arranged one behind the other in the gas flow direction, each having mutually parallel tubes, which are indicated by arrows R in the figure. Each row of tubes in 1.1 to 1.4 has the same number of tubes, each of which is flowed in parallel. The rows of tubes are connected in series on the refrigerant side, that is to say they are connected to each other by refrigerant connections indicated by dashed arrows V. This connection V is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap