Gas-liquid distributor

A technology of gas-liquid distributor and gas-liquid flow, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex structure, low mass transfer efficiency, and only distribution, so as to achieve simple equipment structure and high mass transfer efficiency High, low pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

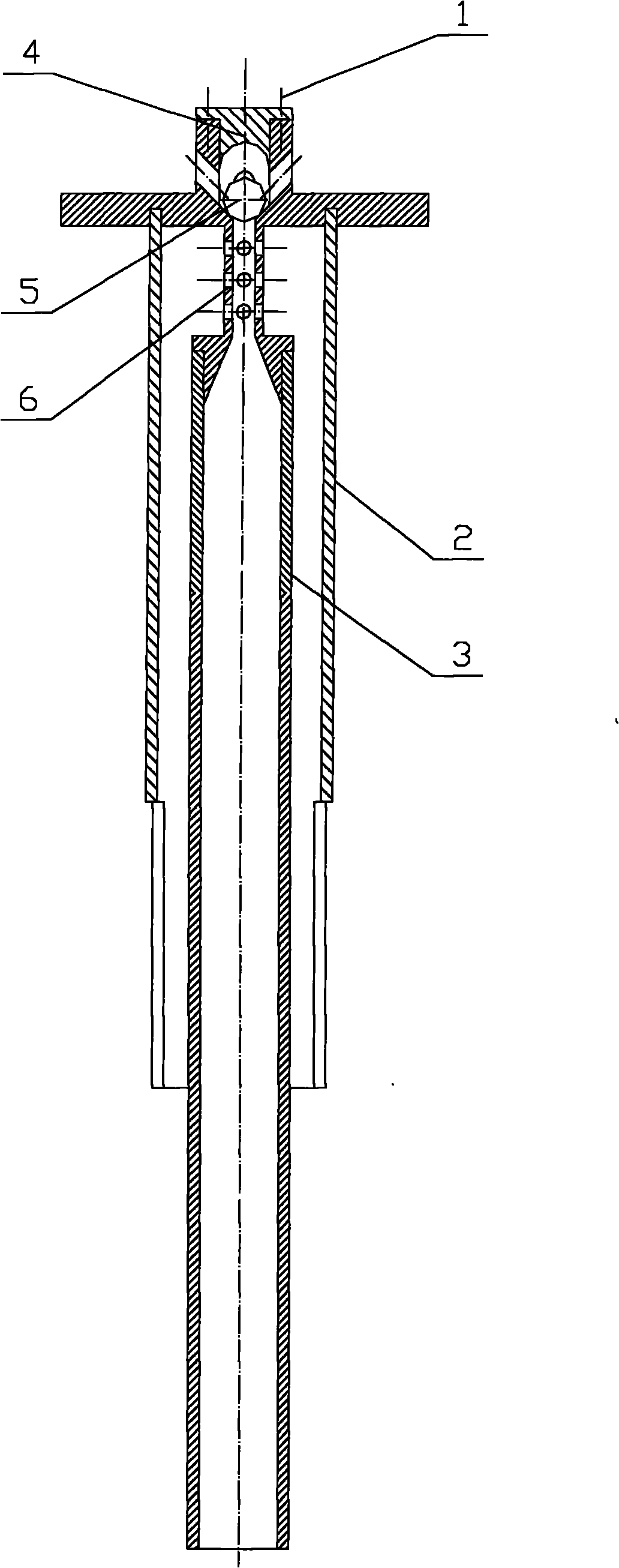

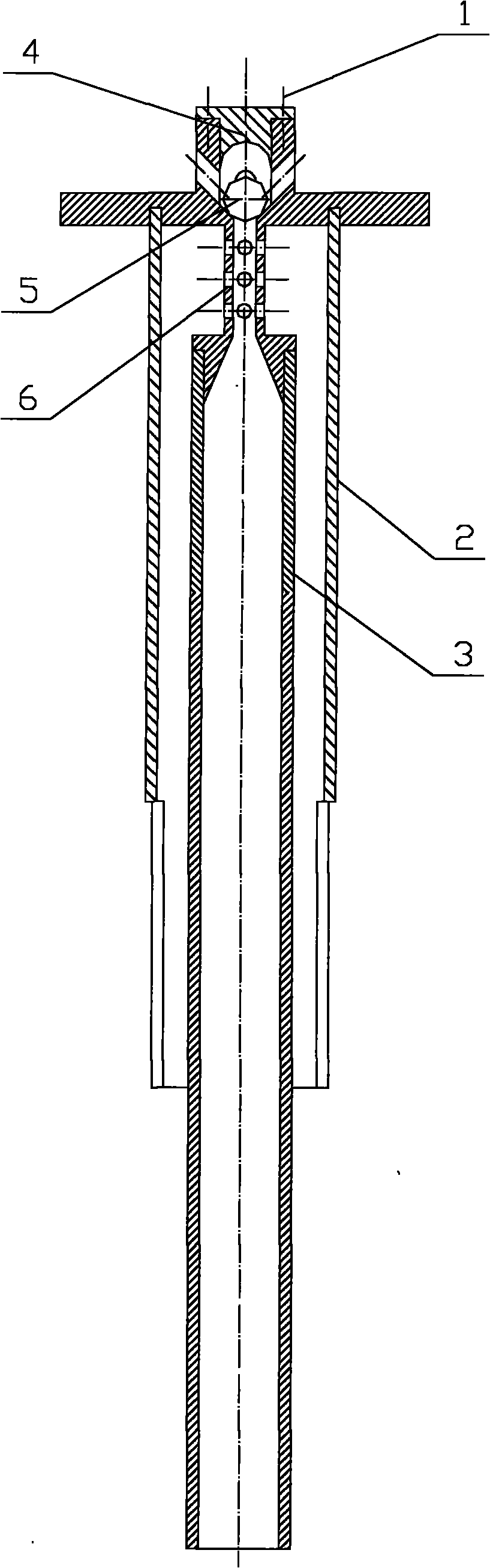

[0013] The gas-liquid distributor of the present invention will be further described in detail below with reference to the accompanying drawings. Such as figure 1 As shown, the gas-liquid distributor of the present invention is composed of a gas-phase cofferdam 2, a liquid catheter 3, a mixing component 6, a check ball 5, an end cap 4 and a screw 1 and the like.

[0014] The gas-liquid distributor of the present invention comprises a gas-phase cofferdam 2 and a catheter 3, the gas-phase cofferdam 2 is set outside the catheter 3, and the two are fixed on the mixing part 6; 1 / 3 to 2 / 3; the annular area between the gas phase cofferdam and the catheter is 1 / 3 to 2 times the cross-sectional area of the catheter, preferably 1 / 2 to 1 times; the area between the gas phase cofferdam and the catheter The annular area forms a gas phase channel, and the catheter extends under the liquid layer to form a liquid phase channel.

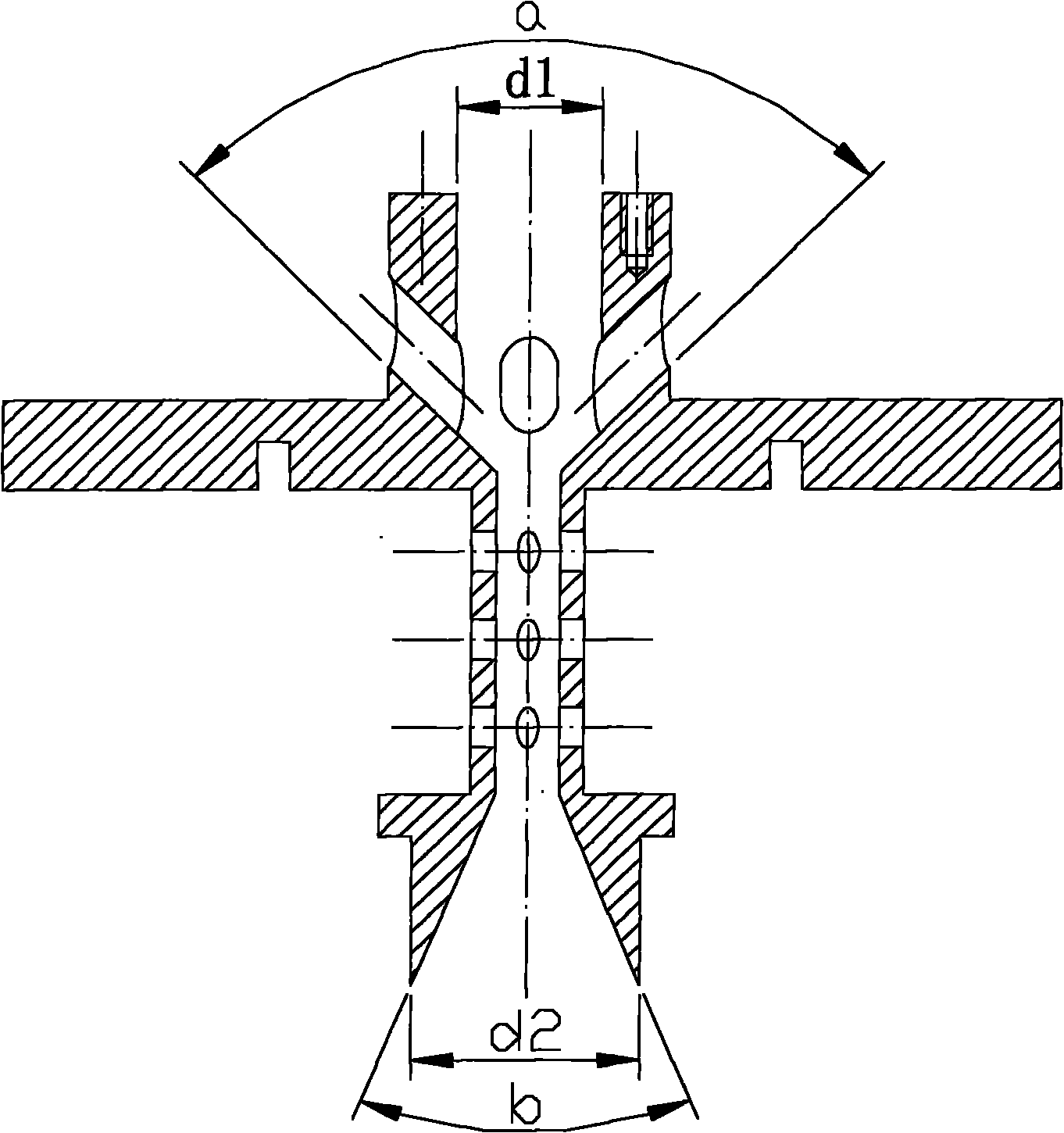

[0015] The mixing unit 6 is sequentially composed of a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com