An online turbidity sensor with defoamer

A turbidity sensor and defoamer technology, applied in the field of detection sensors, can solve the problems of large heat generation, long optical path, large sampling amount, etc., and achieve the effect of obvious defoaming effect, high measurement accuracy and low heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, not to limit the scope of the invention.

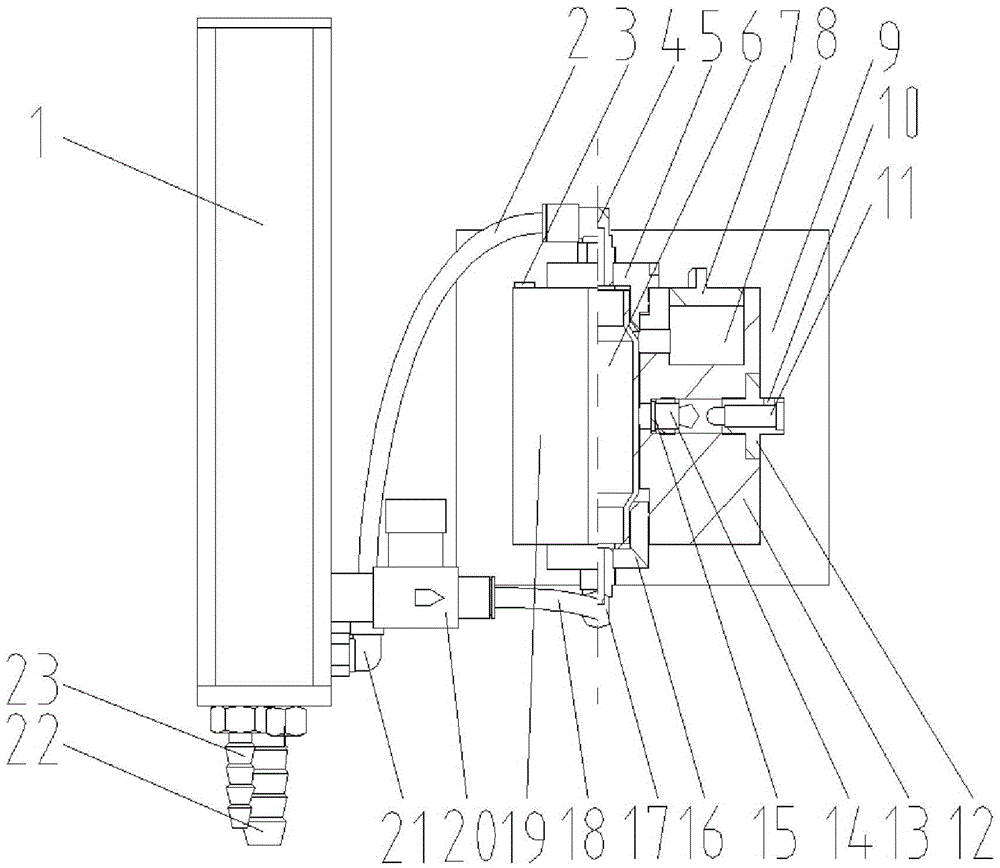

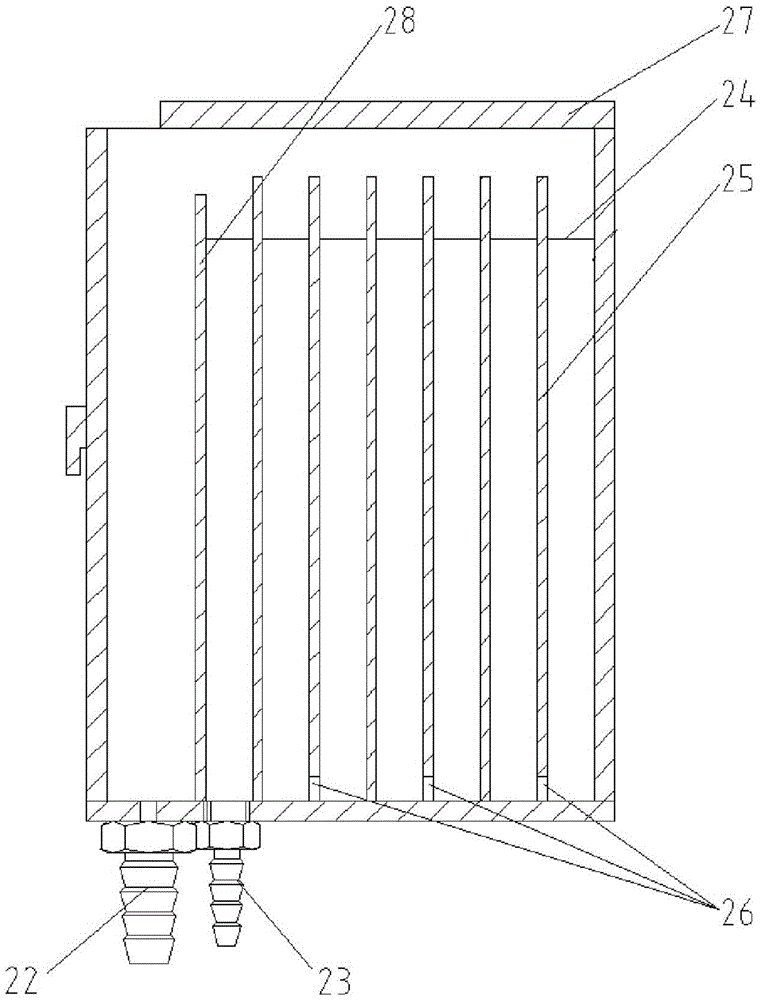

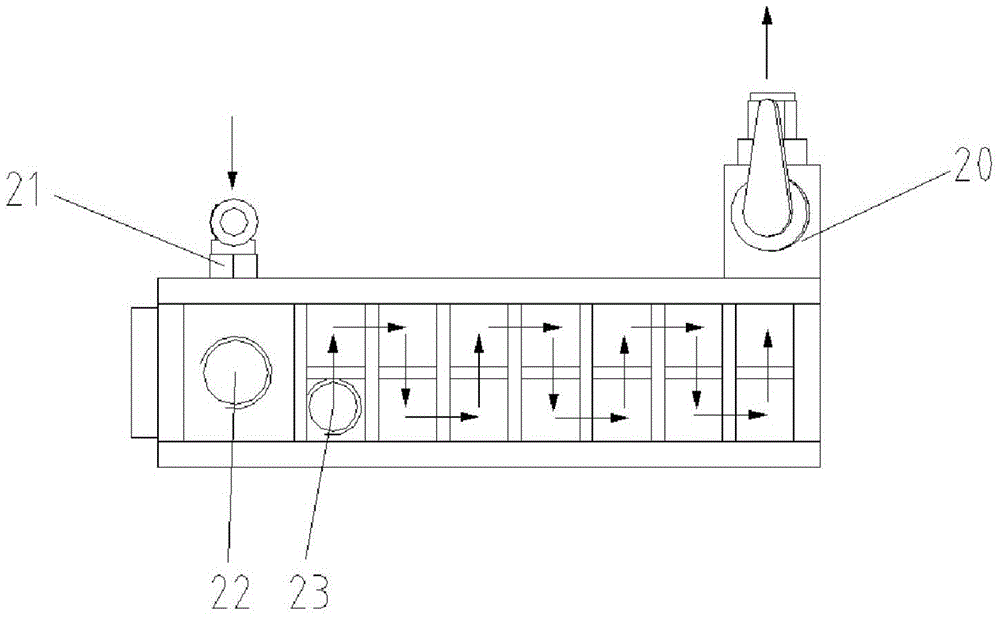

[0034] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, an online turbidity sensor with a defoamer includes a defoamer 1, a sensor, and a mounting plate 9 arranged vertically, and the defoamer 1 includes a shell with an open top and an inner cavity surrounded by the shell , the edge of one side of the bottom of the shell is fixedly provided with a liquid discharge joint 22 connected to the inner cavity, and at the bottom of the shell close to the liquid discharge joint 22 and away from the bottom edge of the shell is fixedly provided with a liquid inlet joint 23 connected with the inner cavity. A front liquid baffle 28 is vertically integrally formed between the bottom, the liquid discharge joint 22 and the liquid inlet joint 23,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap