Experimental device for simulating bolt-connected disk-and-drum rotor of aero-engine

An aero-engine and experimental device technology, applied in the field of rotor dynamics, can solve the problem of not considering the structural characteristics of the thin-walled cylindrical shell of the drum, the inability to characterize the structural characteristics of the flange-bolt connection, and the inability to truly reflect the dynamic characteristics of the disc-drum rotor and stress distribution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

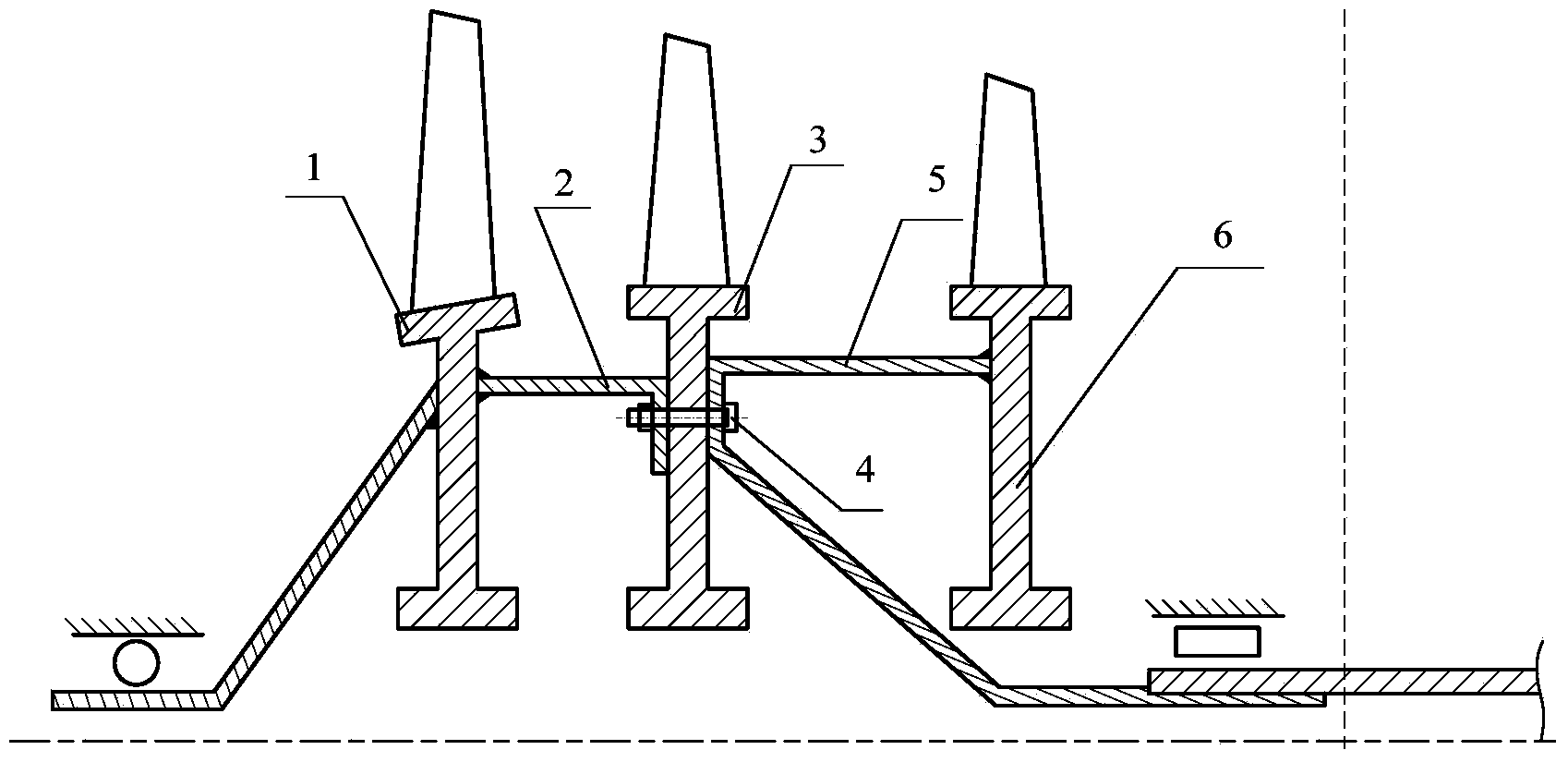

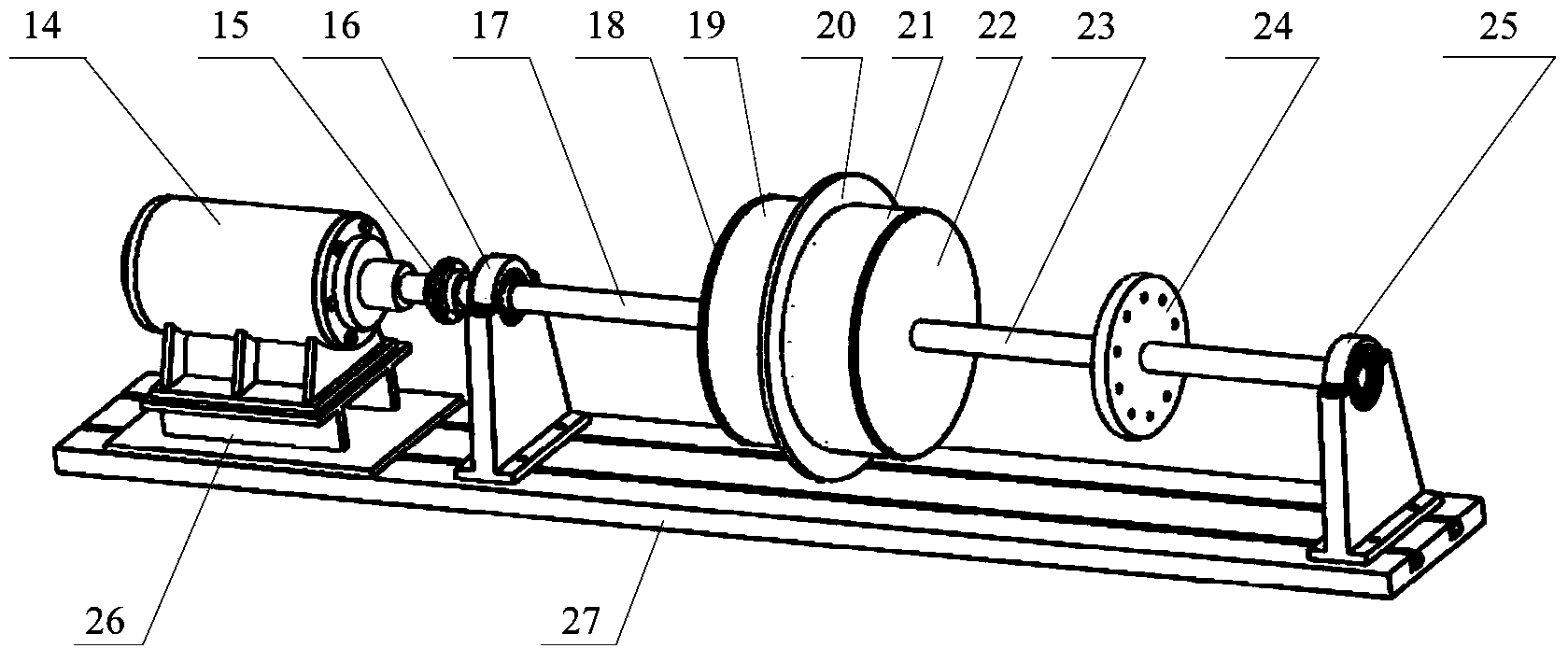

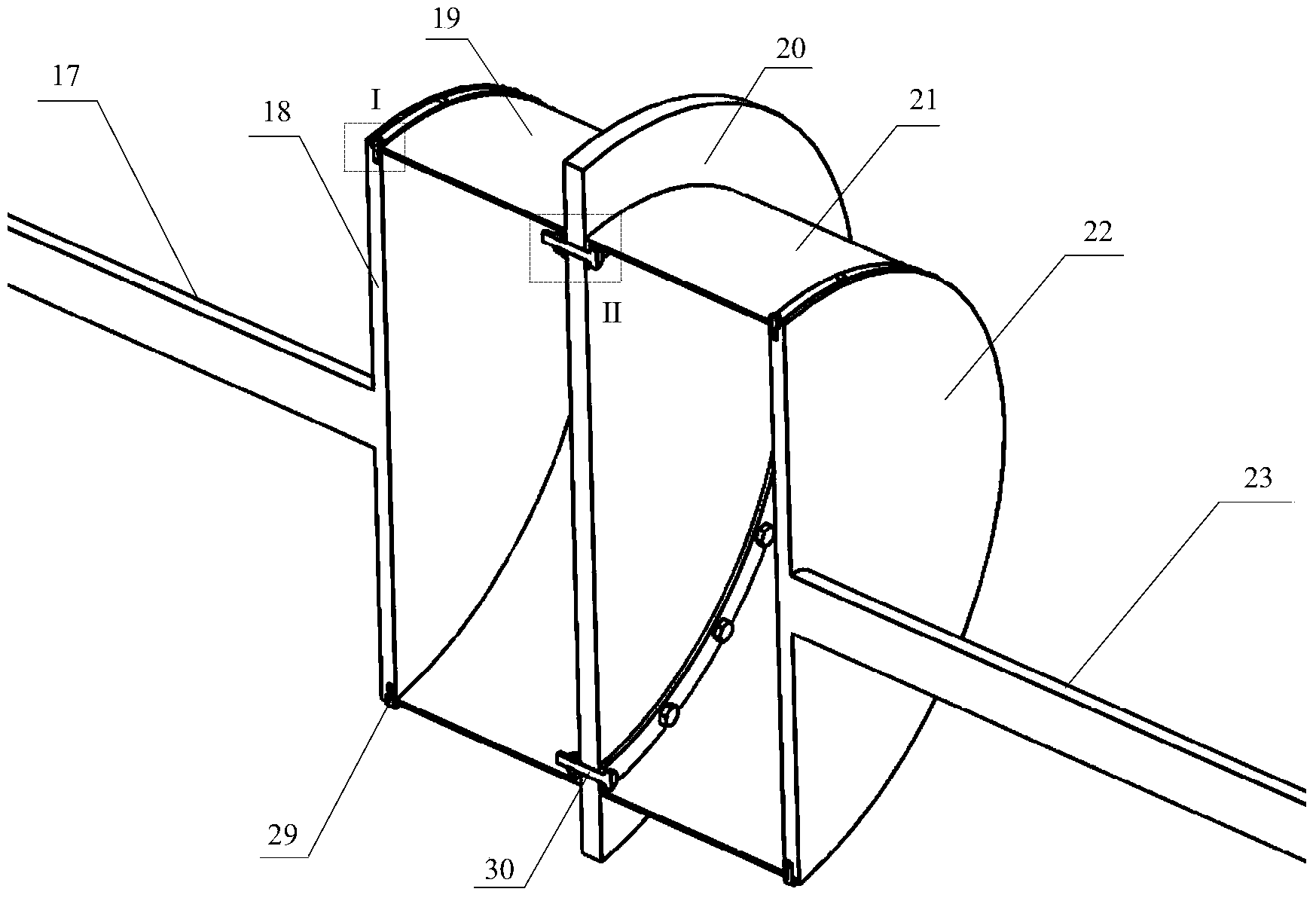

[0024] Such as figure 2 and image 3 As shown, the device is composed of a DC motor 14, an elastic coupling 15, a left bearing seat 16, a right bearing seat 25, a motor seat 26, a test bench base 27, and a disc-drum rotor; the left bearing seat 16, the right The side bearing seat 25 is arranged on the base 27 of the test bench, and a disc-drum rotor is installed between the left bearing seat 16 and the right bearing seat 25; a DC motor 14 is arranged on the outside of the left bearing seat 16, and the DC motor 14 passes through the motor seat. 26 is installed on the test bench base 27, links to each other with the left rotating shaft 17 of the disc-drum rotor stretching out the left side bearing seat 16 through the elastic coupling 15 and drives it to rotate.

[0025] The disc-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com