Capacitive touch screen automatic test method

A technology of capacitive touch screen and automatic test, which is applied in the field of testing, can solve problems such as large errors, capacitive touch screen sensing accuracy does not meet the requirements, and long test time, so as to reduce the defect rate, reduce test time, and improve test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

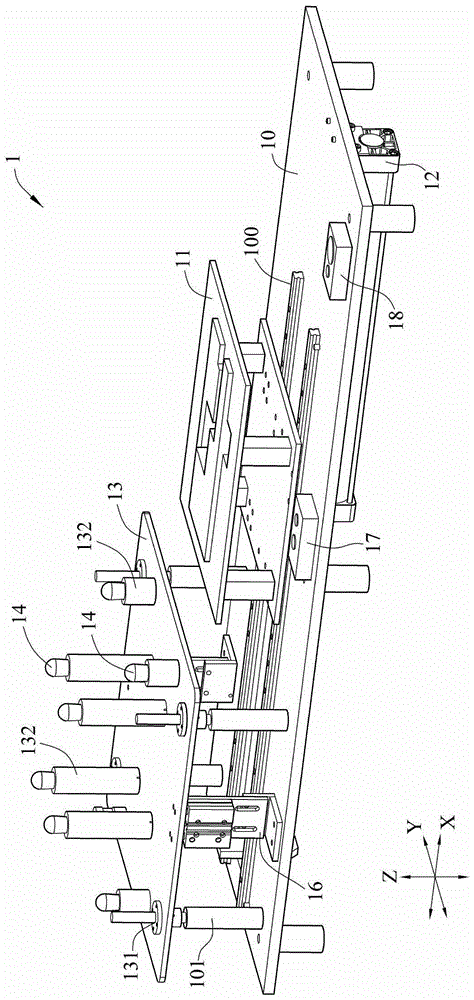

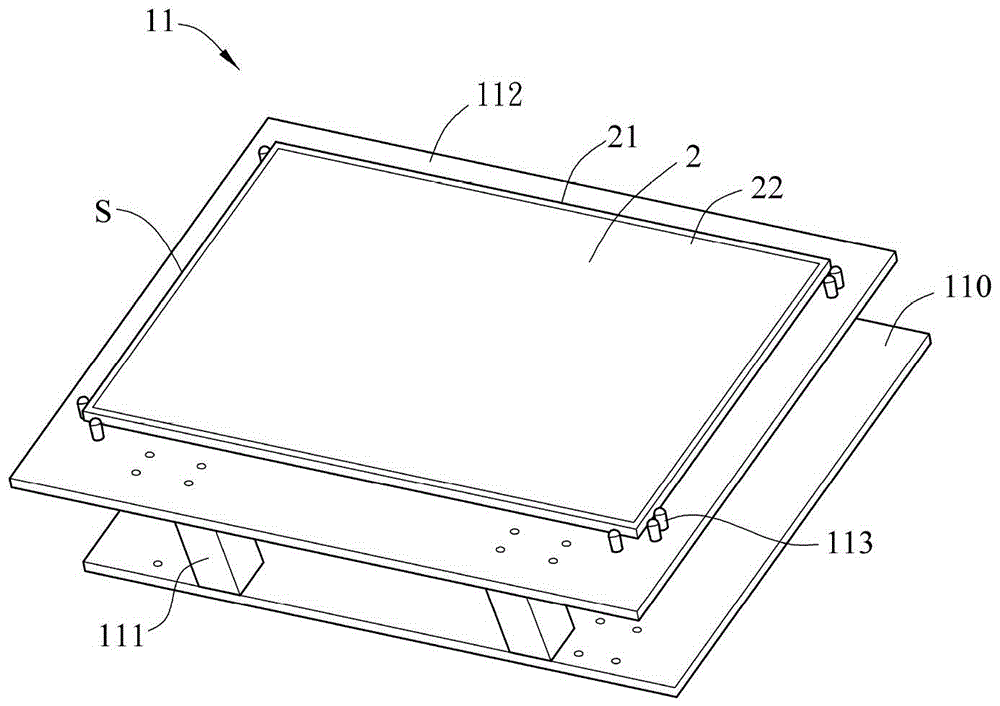

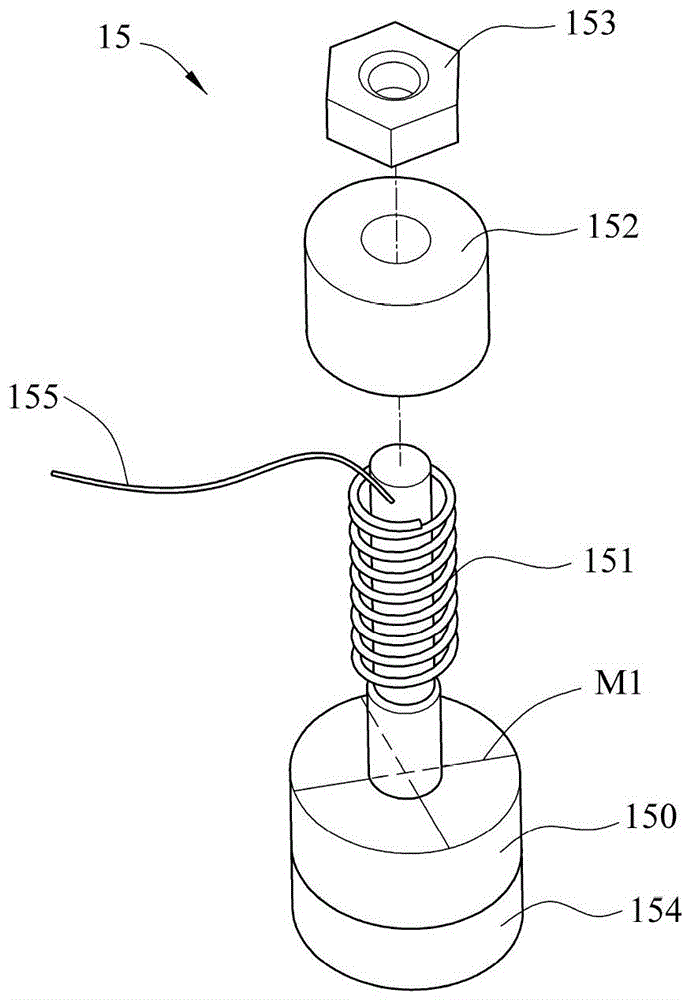

[0025] figure 1 It is a schematic diagram of a capacitive touch screen automatic testing device applying a capacitive touch screen automatic testing method according to a preferred embodiment of the present invention. Please refer to figure 1 . In this embodiment, capacitive touch screen automatic testing device 1 is used for testing capacitive touch screen 2 (such as figure 2 shown) of the display panel 21 (as figure 2 shown) with the sensing panel 22 (as figure 2 shown) assembly tolerances between. The capacitive touch screen automatic testing device 1 comprises a base 10, a carrying platform 11, a driver 12, a transparent substrate 13, a plurality of camera modules 14, conductive elements 15 (such as image 3 shown), cylinder 16 and control module 17. The carrying platform 11 is disposed on the base 10 . The driving member 12 is connected to the carrying platform 11 and the control module 17 . The transparent substrate 13 is movably disposed on the base 10 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com