Wire testing system and method

A testing system and wire technology, applied in the measurement of electricity, measuring devices, measuring electrical variables, etc., can solve the problems of poor scalability, unsuitable for batch testing, and inability to detect multiple wires at the same time, achieving simple software design and flexible testing. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

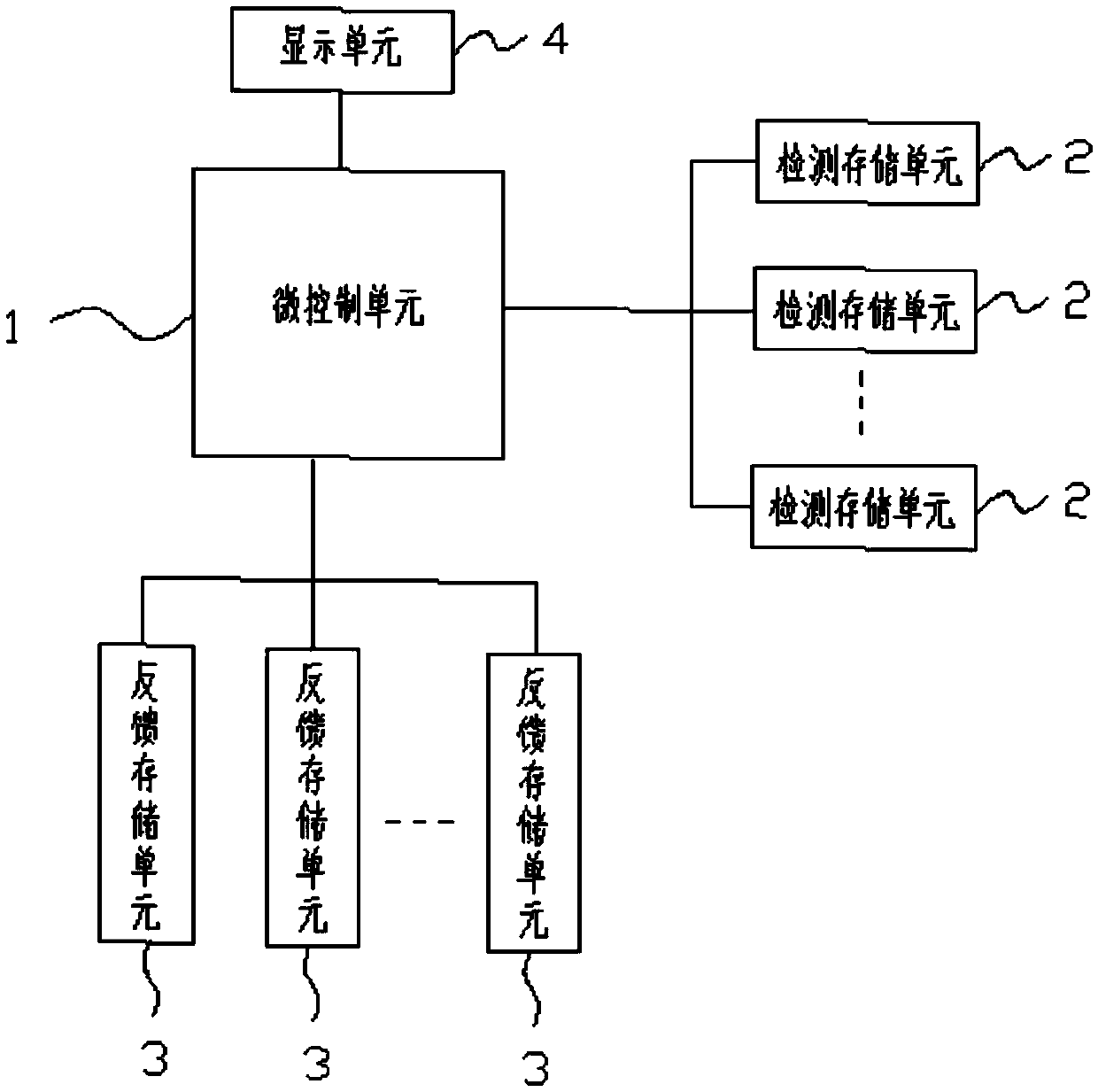

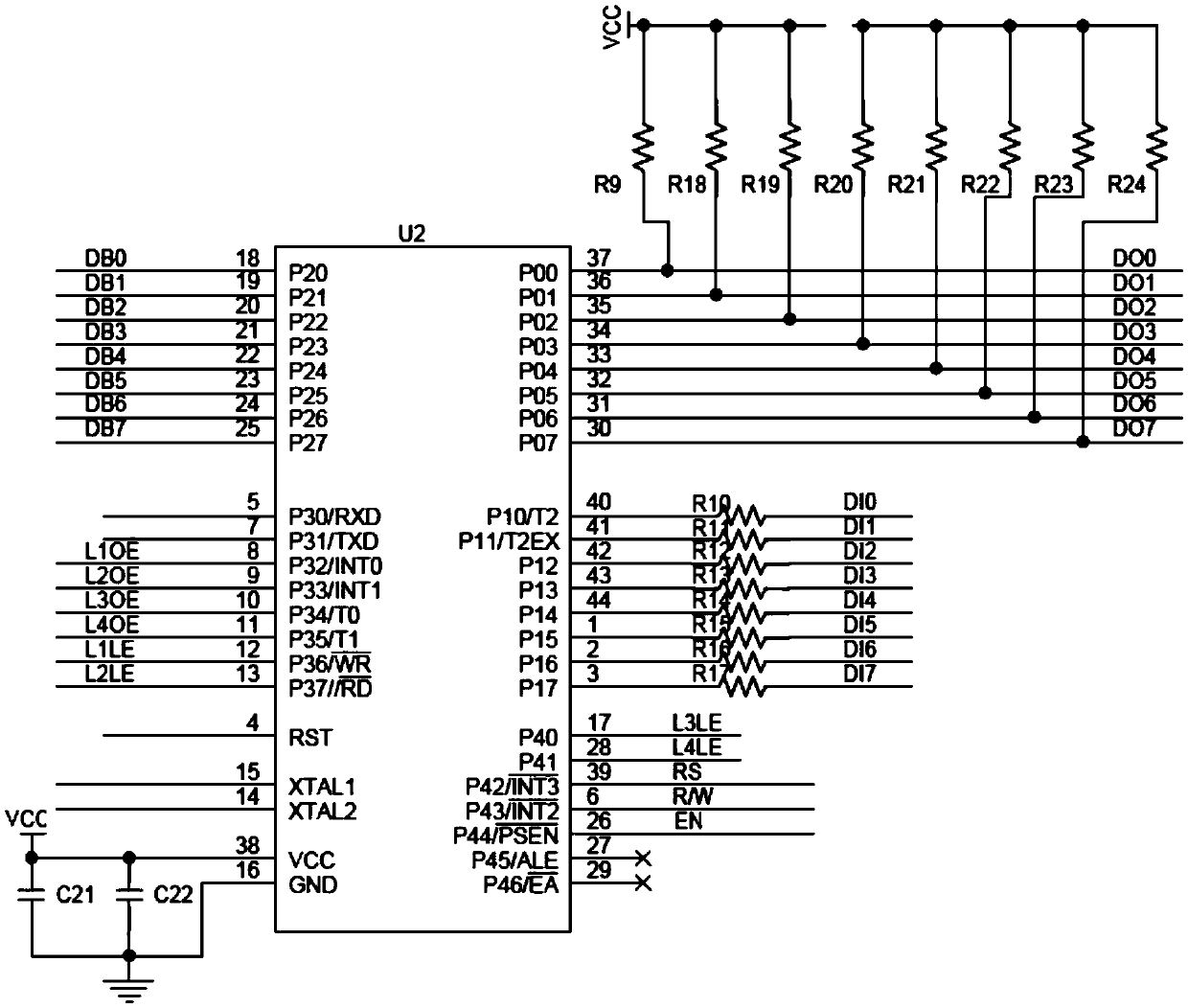

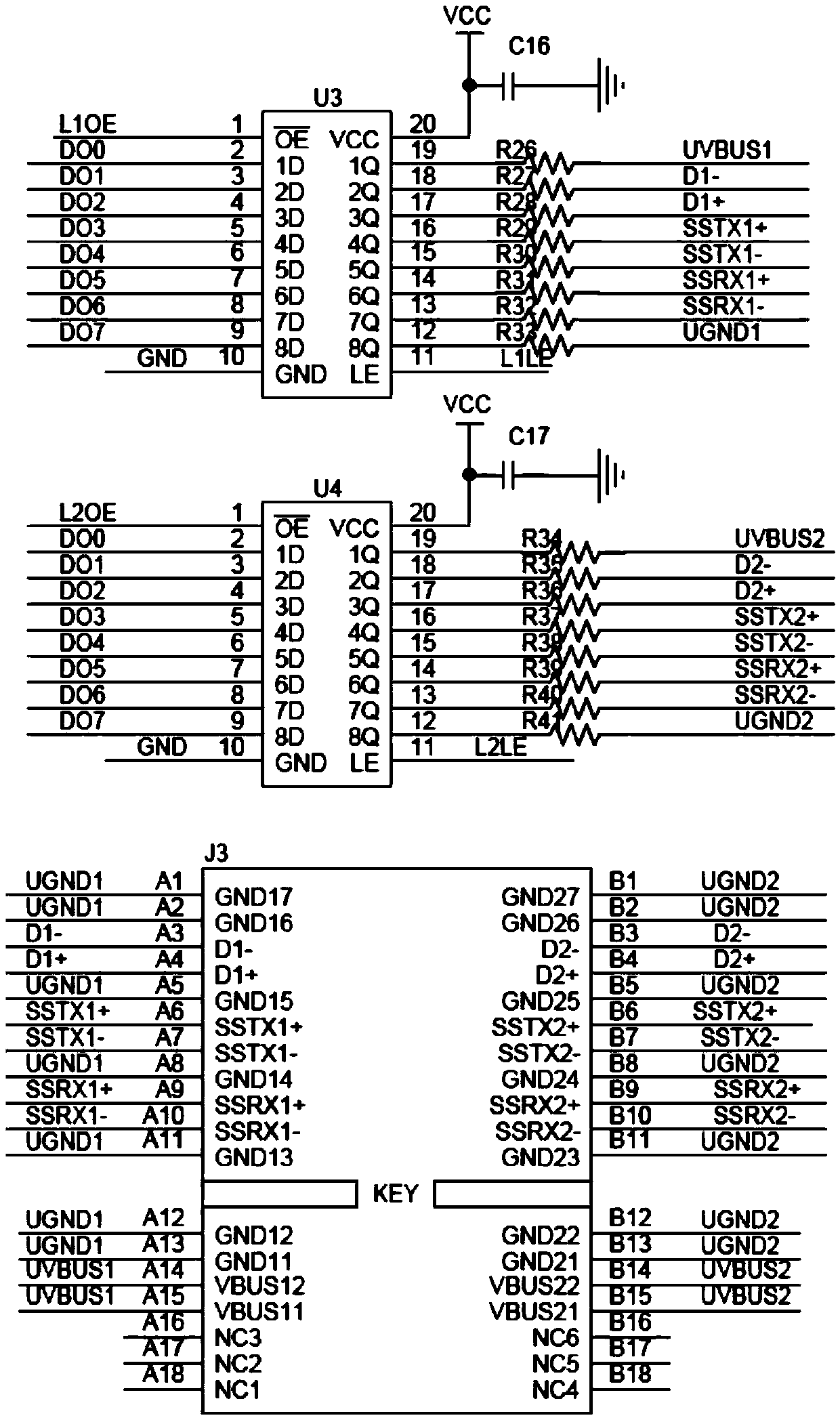

[0039] In order to solve the defects in the prior art that it is impossible to detect multiple wires at the same time, the scalability is poor, and it is not suitable for batch detection, the present invention provides a wire testing system and method, which introduces a detection storage unit and a feedback storage unit on the hardware, and the detection storage unit The detection signal can be cached, and the feedback storage unit can cache the feedback signal. Since the data input ports of all the detection storage units are connected in parallel to the micro control unit, and the data output ports of all the feedback storage units are connected in parallel to the micro control unit, Therefore, the expansion of the number of detection storage units and feedback storage units will not increase the burden on the IO port of the microcontroller unit. It is suitable for a large number of expansion detection storage units to test multiple wires at one time. It is suitable for batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com