Preparation method of high-security aluminum electrolytic capacitor-type lithium cobalt oxide lithium-ion battery

A technology for aluminum electrolytic capacitors and lithium-ion batteries, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrode carriers/collectors, etc., can solve problems such as high cost, poor safety, and restrictions on the popularization and application of lithium cobalt oxide, and achieve processing Convenience, avoiding explosion accidents, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

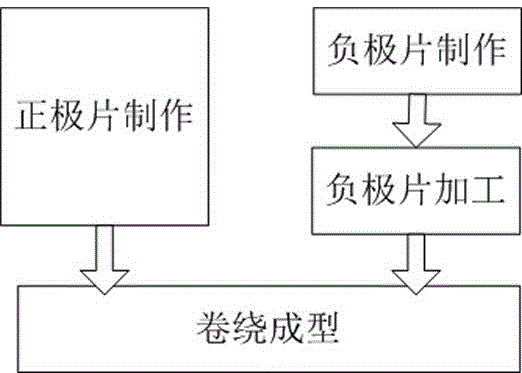

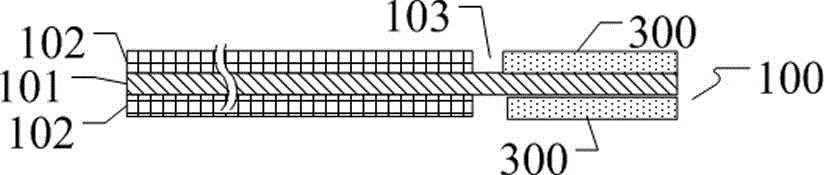

[0034] Such as Figure 1~5 As shown, the invention discloses a method for preparing a high-safety aluminum electrolytic capacitor type lithium cobalt oxide lithium-ion battery, comprising the following steps:

[0035] Positive sheet production: 85%-95% by weight of lithium cobalt oxide material is used as positive electrode active material, 1%-10% of conductive agent and 1%-15% of binder are dissolved in solvent to make lithium cobalt oxide positive electrode slurry , with the anode aluminum foil of an aluminum electrolytic capacitor as the positive electrode collector 201, the positive electrode slurry of lithium cobaltate is coated on both sides to the positive electrode collector to form the positive electrode active material layer 202, and the tail of the positive electrode collector 201 is provided with an uncoated positive electrode The positive electrode bare area 203 of the active material layer 202 is then dried to make a pole piece, and then the pole piece is rolled,...

Embodiment 2

[0044] Such as Figure 1~5 As shown, the invention discloses a method for preparing a high-safety aluminum electrolytic capacitor type lithium cobalt oxide lithium-ion battery, comprising the following steps:

[0045] Positive sheet production: 85%-95% by weight of lithium cobalt oxide material is used as positive electrode active material, 1%-10% of conductive agent and 1%-15% of binder are dissolved in solvent to make lithium cobalt oxide positive electrode slurry , with the anode aluminum foil of an aluminum electrolytic capacitor as the positive electrode collector 201, the positive electrode slurry of lithium cobaltate is coated on both sides to the positive electrode collector to form the positive electrode active material layer 202, and the tail of the positive electrode collector 201 is provided with an uncoated positive electrode The positive electrode bare area 203 of the active material layer 202 is then dried to make a pole piece, and then the pole piece is rolled,...

Embodiment 3

[0054] Such as Figure 1~5 As shown, the invention discloses a method for preparing a high-safety aluminum electrolytic capacitor type lithium cobalt oxide lithium-ion battery, comprising the following steps:

[0055]Positive sheet production: 85%-95% by weight of lithium cobalt oxide material is used as positive electrode active material, 1%-10% of conductive agent and 1%-15% of binder are dissolved in solvent to make lithium cobalt oxide positive electrode slurry , with the anode aluminum foil of an aluminum electrolytic capacitor as the positive electrode collector 201, the positive electrode slurry of lithium cobaltate is coated on both sides to the positive electrode collector to form the positive electrode active material layer 202, and the tail of the positive electrode collector 201 is provided with an uncoated positive electrode The positive electrode bare area 203 of the active material layer 202 is then dried to make a pole piece, and then the pole piece is rolled, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com