Novel bidirectional stroke compressor

A compressor and stroke technology, applied in contact operating parts, grain processing and other directions, can solve the problems that affect the normal operation of related equipment, the position of the actuator cannot be triggered in time, and the on-site adaptability is poor, so as to avoid the problem that the stroke switch cannot be triggered. , Reduce trigger dead zone, trigger sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

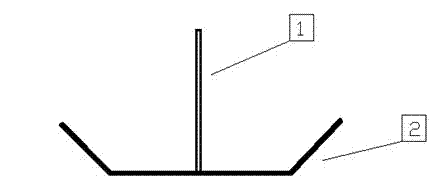

[0012] Such as figure 1 , 2 , as shown in 3, one A new type of two-way stroke compressor, including: a two-way trigger device and a fixing device. The two-way trigger device can meet the travel requirements of the opening direction and the closing direction. The distance between the trigger surface and the fixing device can be determined according to the actual situation on site. Situation adjustment, the total length of the fixing device can be based on the operation of the equipment, reducing the trigger dead zone, and avoiding the malfunction of the main equipment caused by the logical protection action caused by the switch trigger not in place.

[0013] Weld the fixing device part 1 to the plug plate of the outlet door of the coal mill. When the plug plate is opened, it will drive the compressor to move together. When the compressor touches the limit switch, it will press the switch and the open signal will be transmitted through the signal line. In the DCS control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com