Device and method for correcting motor rotor shaft

A technology of a motor rotor and a correction device, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of difficult control of the correction value, increased vibration and noise of the complete set of equipment, time-consuming and other problems, and achieves simple and convenient correction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

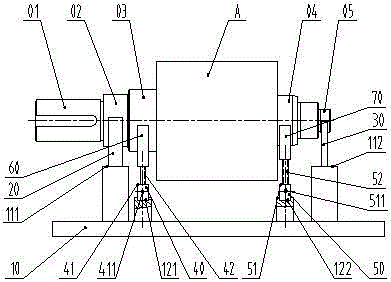

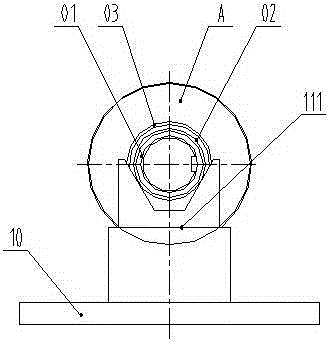

[0018] As shown in the figure, the motor rotor shaft correction device and method, the device includes a chassis 10, a front V-shaped block 20, a rear V-shaped block 30, a front support 40, a rear support 50, a front V-shaped bracket 60, and a rear V-shaped Support 70, the front support 40 includes a front stud 41 and a front screw 42, and the rear support 50 includes a rear stud 51 and a rear screw 52; when the shaft 01 beats, the front bearing block 02 of the motor rotor A rests on the front V block 20, the rear bearing gear 05 rests on the rear V-shaped block 30; when the output shaft is corrected, the front V-shaped bracket 60 is raised to support the front correction section 03, and the rear V-shaped bracket 70 is raised to support the rear correction section 04

[0019] In the above embodiment, the motor rotor output shaft correction device is: the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com