Winding wire threading mechanism used for motor stator of closed-type slot

A motor stator and winding wire technology, applied in the field of winding wire threading mechanism, can solve the problems of labor-consuming, low production efficiency, etc., and achieve the effects of reducing labor intensity, labor-saving operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

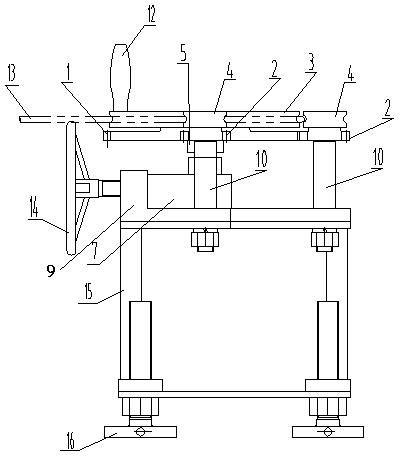

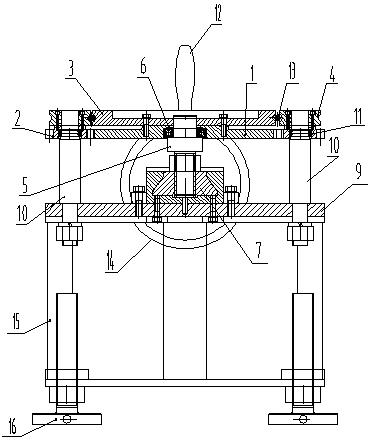

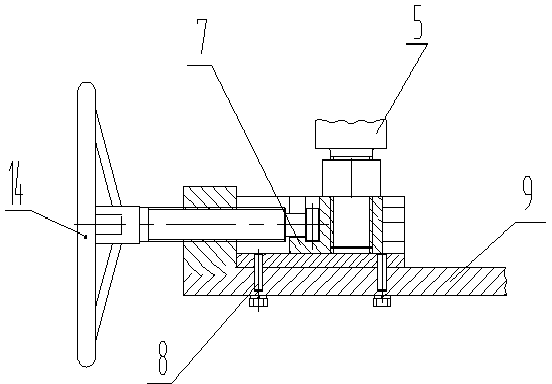

[0033] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0034] Such as Figure 7 and Figure 8 As shown, a winding wire threading mechanism for a closed slot motor stator according to the present invention includes a stator bracket 19 on which a stator core 20 is installed. The stator core 20 is a closed slot stator, and the closed slot silicon The winding wires on the steel sheet 21 cannot be made by winding or embedding, and the waterproof insulating winding 13 can only be passed into the corresponding wire groove of the stator core 20 by threading. In the prior art, the threading operation can only be done manually by using the stator bracket 19 in clear water. Soaking the waterproof insulating winding 13 in clear water for the threading operation has two functions: lubricating the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com