Thermoelectric conversion element and thermoelectric conversion method

A technology of thermoelectric conversion and components, applied in the direction of electrical components, thermoelectric devices, circuits, etc., can solve problems such as inability to convert

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

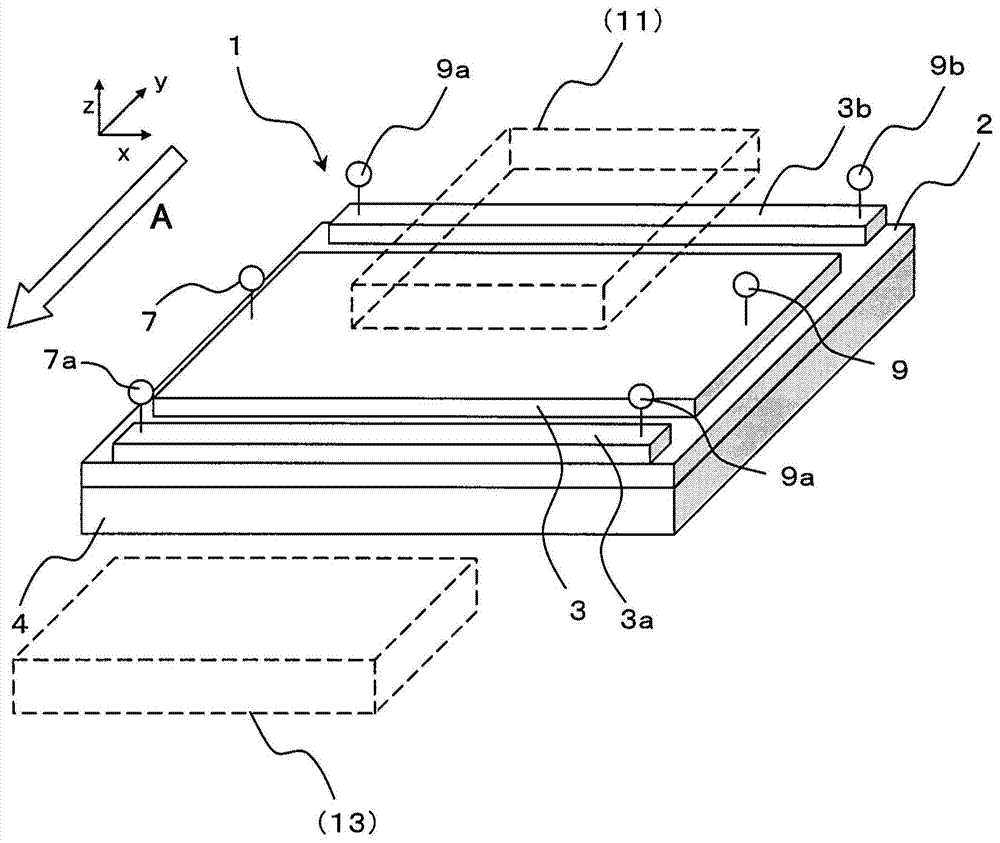

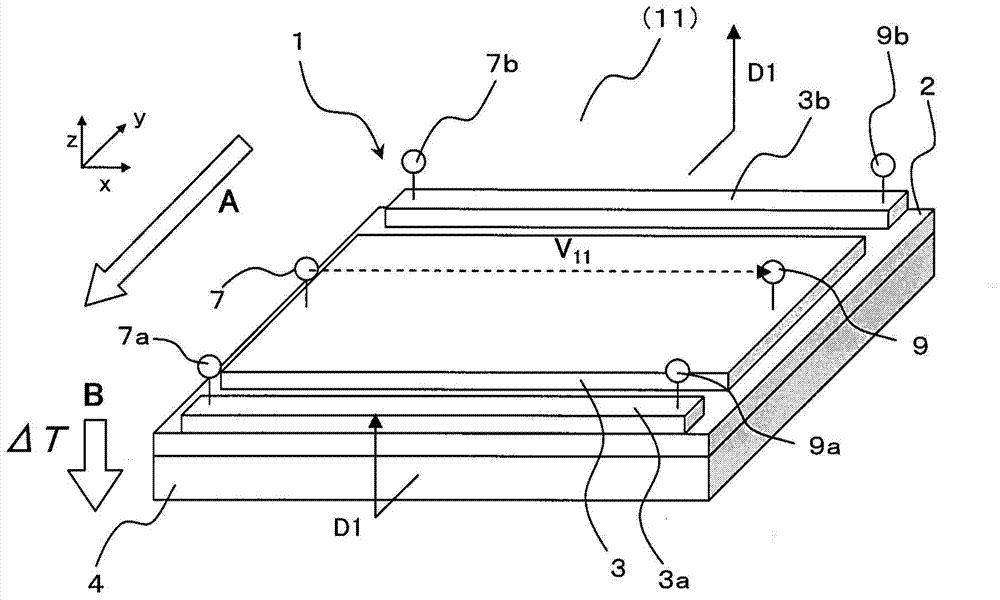

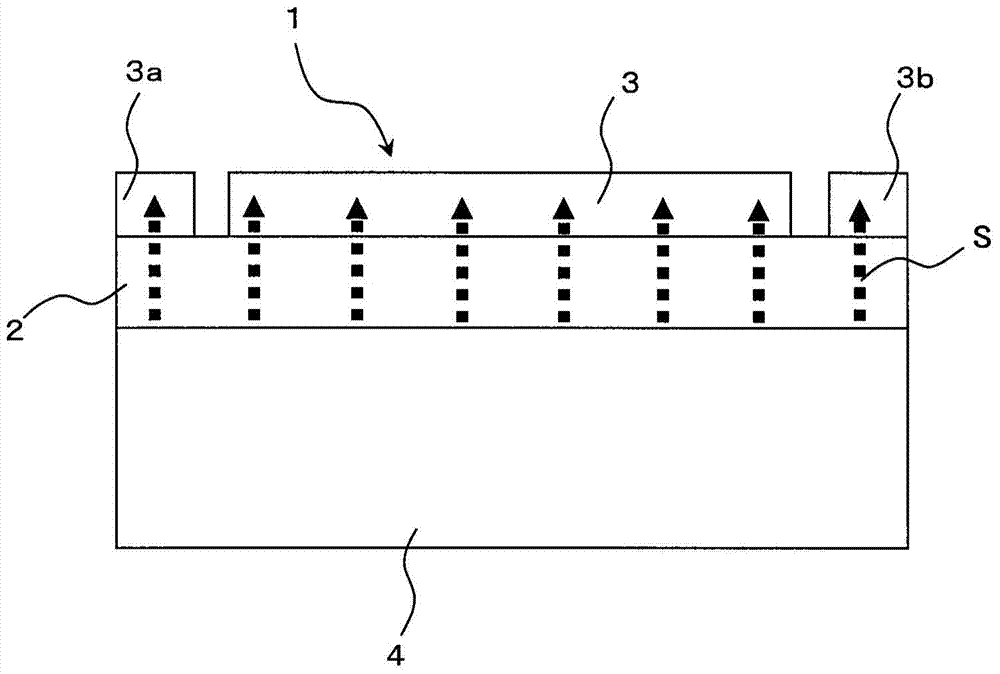

[0230] The thermoelectric conversion element 1 according to the first embodiment was manufactured. Specific steps are as follows:

[0231] First, as for the substrate 4, gallium-gadolinium-gallium garnet (hereinafter referred to as "GGG"; its composition is Gd 3 Ga 5 o 12 ) plane of the substrate (111). As for the magnetic film 2, an yttrium iron garnet film (the composition of which is BiY 2 Fe 5 o 12 ; hereinafter referred to as "Bi:YIG"). For the electrodes 3, 3a and 3b, Pt was used. In this case, the thickness of the GGG substrate was set to 0.7 mm, the thickness of the Bi:YIG film was set to 0.3 mm, and the thickness of the Pt electrode was set to 10 nm.

[0232] The Bi:YIG magnetic film 2 was formed by an aerosol deposition method. As for the raw material of Bi:YIG, Bi:YIG fine particles having a diameter of 300 nm were used. The Bi:YIG fine particles were stored in the aerosol generator container, and the GGG substrate was fixed to a holder provided in the fil...

example 2

[0235] A thermoelectric conversion element 1a according to the second embodiment was manufactured. Specific steps are as follows:

[0236] As the substrate 4a, a thermally conductive anisotropic substrate containing carbon fibers oriented in epoxy resin as a filler was used. The carbon fiber is oriented in a direction perpendicular to the plane with respect to the substrate, and has a large thermal conductivity in this direction.

[0237] As for the magnetic film 2, a yttrium iron garnet film (BiY 2 Fe 5 o 12 ). For the electrodes 3, 3a and 3b, Pt was used. In this case, the thickness of the substrate 4a was set to 0.3 mm, the thickness of the Bi:YIG film was set to 0.1 mm, and the thickness of the Pt electrode was set to 10 nm.

[0238] The Bi:YIG magnetic film 2 was formed by an aerosol deposition method. As for the raw material of Bi:YIG, Bi:YIG fine particles having a diameter of 300 nm were used. Bi:YIG fine particles were stored in the aerosol generator container...

example 3

[0241] A thermoelectric conversion element 1b according to the third embodiment was manufactured. Specific steps are as follows:

[0242] As for the substrate 4b having anisotropic heat conduction characteristics, a polyimide substrate having a thickness of 0.3 mm having a rear surface on which slits are formed, each having a thickness of 0.1 mm, is used. width and depth of 0.2mm.

[0243] As the magnetic film 2, a Bi:YIG film was used. For the electrodes 3, 3a and 3b, Pt was used. In this case, the thickness of the Bi:YIG film was set to 0.1 mm, and the thickness of the Pt electrode was set to 10 nm.

[0244] The Bi:YIG magnetic film 2 was formed by an aerosol deposition method. As for the raw material of Bi:YIG, Bi:YIG fine particles having a diameter of 300 nm were used. The Bi:YIG fine particles were stored in the aerosol generator container, and the substrate 4b was fixed to a holder provided in the film forming chamber. In this state, Bi:YIG fine particles are suck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com